Titanium Alloy Mechanical Properties

Titanium alloy yana da abũbuwan amfãni daga haske nauyi, high takamaiman ƙarfi, mai kyau lalata juriya, don haka ana amfani da ko'ina a cikin mota masana'antu, aikace-aikace na titanium gami ne mafi m inji tsarin.Akwai fa'idodi da yawa don yin sassan injin daga gami da titanium.Ƙananan ƙananan ƙarfe na titanium na iya rage yawan ƙananan motsi na sassa masu motsi, kuma titanium bawul spring zai iya ƙara yawan vibration kyauta, rage rawar jiki, inganta saurin injin da ƙarfin fitarwa.

Rage inertial taro na motsi sassa, don rage gogayya karfi da kuma inganta man fetur yadda ya dace na inji.Zaɓin alloy na titanium zai iya rage nauyin nauyin sassa masu dangantaka, rage girman sassa, don rage yawan injin da dukan abin hawa.Rage yawan abubuwan da ba a haɗa su ba yana rage girgizawa da hayaniya kuma yana inganta aikin injin.

Yin amfani da kayan aikin titanium a wasu sassa na iya inganta jin daɗin ma'aikata da kuma kyawun motoci.A cikin aikace-aikacen masana'antar kera motoci, gami da titanium ya taka muhimmiyar rawa wajen ceton makamashi da rage yawan amfani.Duk da waɗannan kyawawan kaddarorin, sassan titanium da gami har yanzu ba a yi amfani da su sosai a cikin masana'antar kera motoci ba saboda matsaloli kamar tsadar farashi, ƙarancin tsari da ƙarancin aikin walda.

Tare da haɓaka fasahar samar da kayan aikin kusa-net na titanium gami da fasahar walda ta zamani kamar waldar lantarki, walƙiya baƙar plasma da walƙiyar laser a cikin 'yan shekarun nan, matsalolin ƙirƙira da walƙiya na alloy na titanium ba sune mahimman abubuwan da ke hana aikace-aikacen ba. titanium alloy.Babban dalilin da ya sa yin amfani da aikace-aikacen duniya na titanium gami a cikin masana'antar mota shine babban farashi.

Farashin titanium alloy ya fi na sauran karafa, duka a farkon smelting da aiki na gaba na karfe.Farashin sassan titanium da aka yarda da masana'antar kera shine $ 8 zuwa $ 13 / kg don haɗa sanduna, $ 13 zuwa $ 20 / kg don bawuloli, kuma ƙasa da $ 8 / kg don maɓuɓɓugan ruwa, tsarin shayewar injin da kayan ɗamara.A halin yanzu, farashin sassan da aka samar da titanium ya fi waɗannan farashin.Kudin samar da takardar titanium ya fi sama da $33/kg, wanda shine sau 6 zuwa 15 na takardar aluminum da sau 45 zuwa 83 na takardar karfe.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

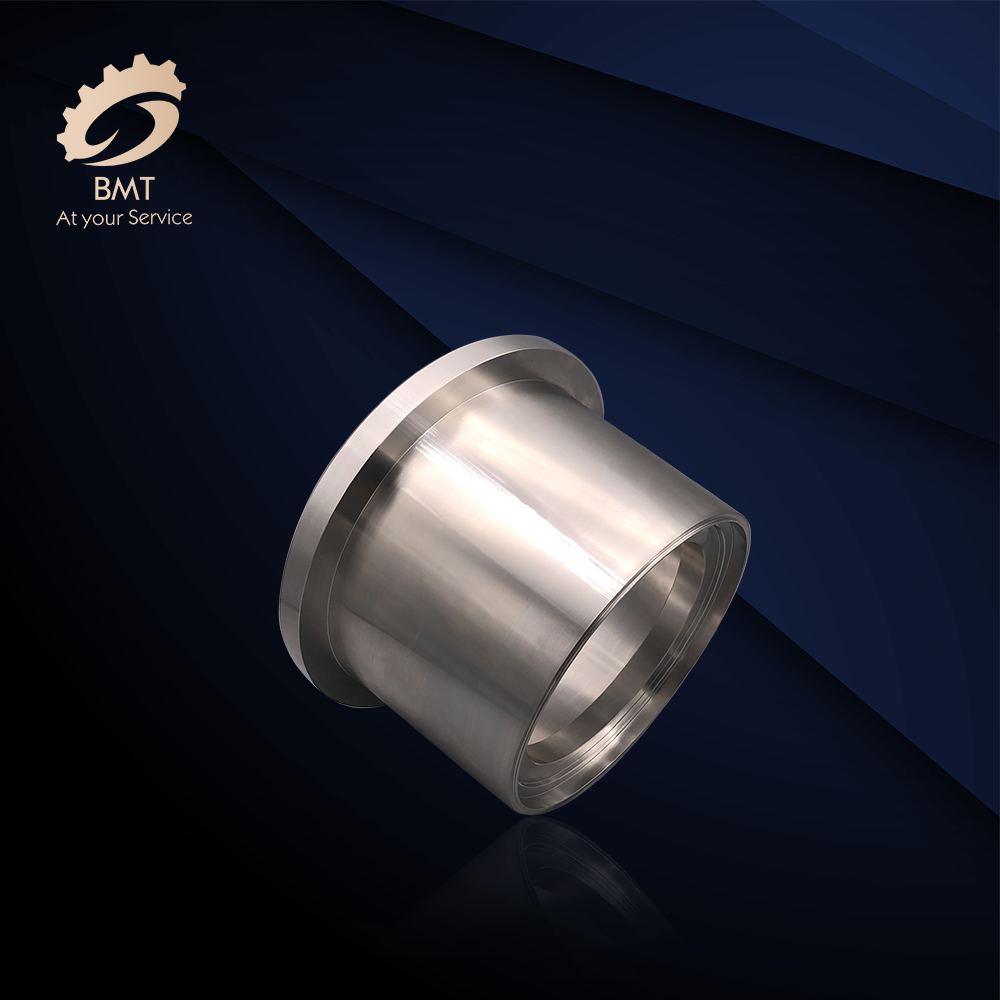

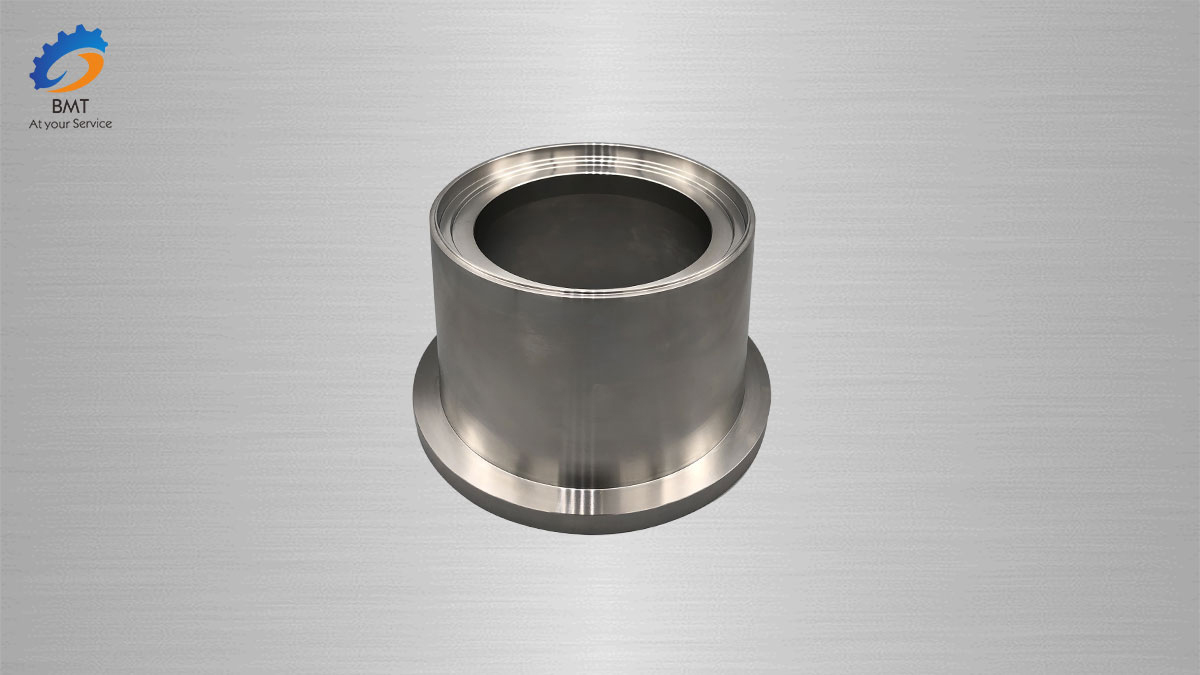

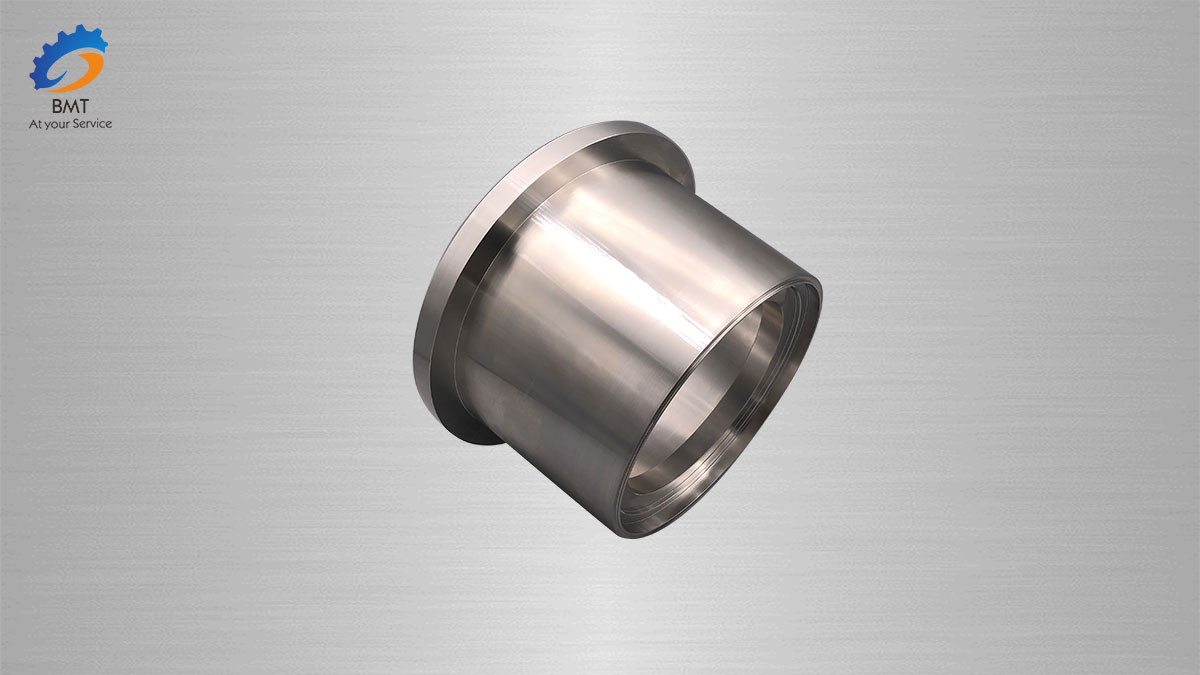

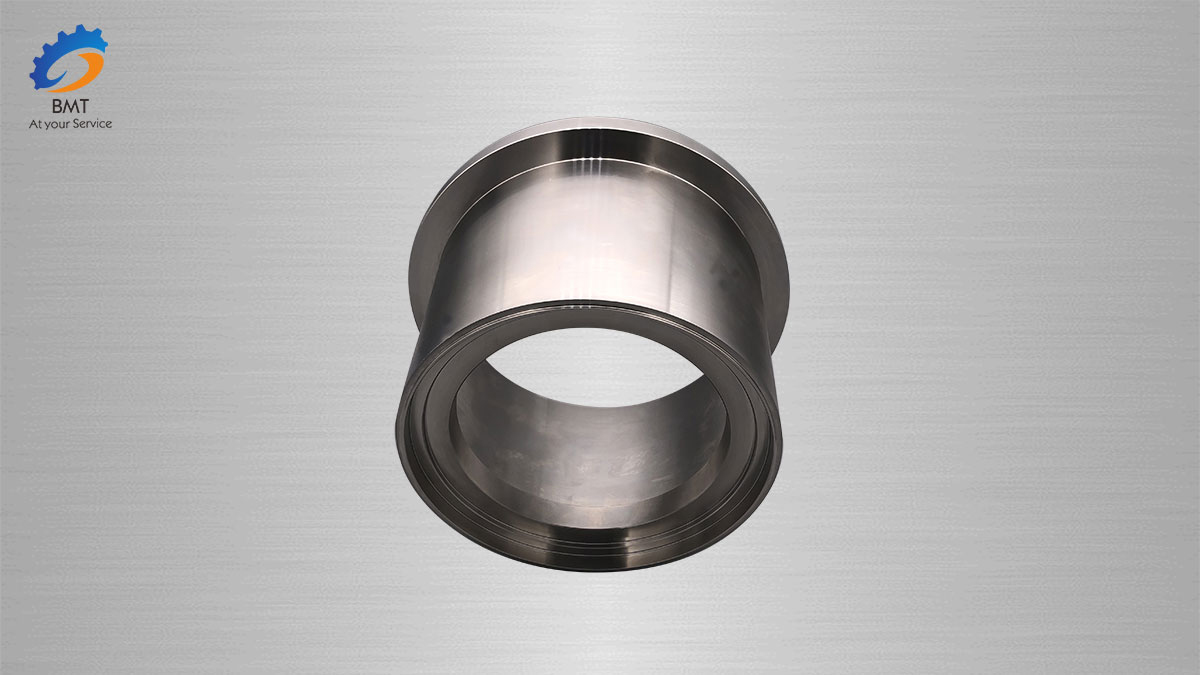

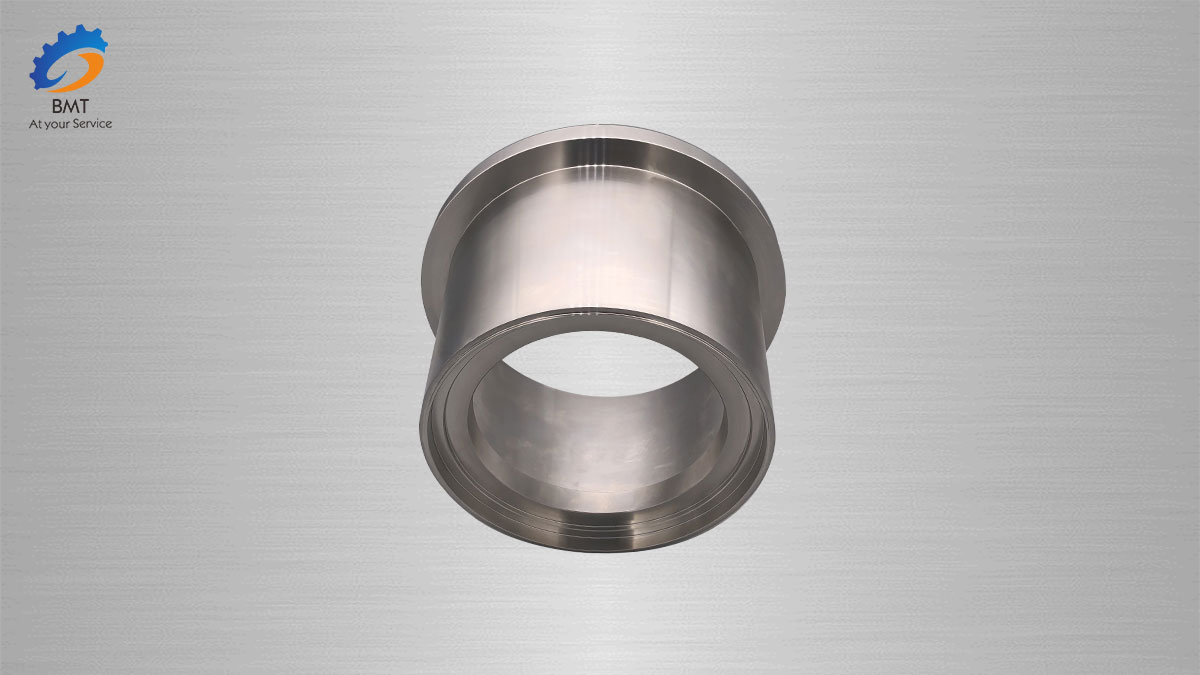

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes