CNC Machining mara daidaituwa

Mashin sarrafa lambobi wani nau'in aiki ne wanda ba daidai ba, wanda ke canza girman kayan aikin ko aikin aikin.Lokacin amfani da Injin CNC zuwa sassa na inji, mai fasaha dole ne ya rubuta duk tsarin fasaha, sigogin fasaha da bayanan ƙaura da aka haɗa cikin shirin, kuma ta hanyar bayanan dijital da aka rubuta a cikin matsakaicin sarrafawa don sarrafa sarrafa kayan aikin injin.

Don haka ana iya ganin cewa fasahar sarrafa na'ura ta CNC da fasahar sarrafa kayan aikin injin gabaɗaya kusan iri ɗaya ne a ƙa'ida, amma duk aikin sarrafa na'ura na CNC yana aiki kuma yana da kyau, duk da haka, yana da nasa halaye.

Hanyoyin sarrafa mashin ɗin ƙira na ƙima da kwararar tsari

1. Tsarin Samfura:

Tsarin musayar albarkatun ƙasa zuwa samfuran ana kiransa tsarin samarwa.Production tsari yafi hada da sufuri da kuma ajiya na albarkatun kasa, samar da shirye-shiryen, shirye-shiryen na aiki blank, inji aiki, surface jiyya, taro, gwaji, debugging, anti-oxidation aiki da shiryawa na kayayyakin, da dai sauransu

Hakanan za'a iya raba tsarin samarwa zuwa tsarin samar da injin gabaɗaya ko tsarin samar da sashe ɗaya, dangane da tsarin samar da dukkan haɗin gwiwar masana'anta ko tsarin samar da bita guda ɗaya.

2. Tsarin Fasaha:

A cikin ƙayyadaddun tsari na samarwa, canza siffar da girman kayan da ba komai ba kai tsaye, canza zuwa samfurin da muke buƙata, kuma sanya samfuran da aka gama ko samfuran da aka gama da su da aka sani da tsarin fasaha.Tsarin fasaha muhimmin bangare ne mai mahimmanci kuma mai mahimmanci na dukkanin tsarin samarwa.Babban ɓangare na aikin sarrafa masana'anta shine tsarin samar da kayan aikin injiniya.

Menene Abubuwan Gudun Tsarin Tsarin mMachining?

1. Shirye-shiryen Tsarin Injini:

Machining tsarin yana nufin wani aiki ko saitin ma'aikatan aiki, aiki a wani ƙayyadadden wuri ko a ingantattun injunan sarrafawa, don ɗayan ko fiye da sassa don kammalawa ta hanyar aikin mashin ɗin, tsarin mashin ɗin shine tushen sashin layin sarrafa injin. , Har ila yau, shine ginshiƙi na tsara sashin shirin samarwa;

2. Shigar da Kayan Aiki:

Matsa sashin akan injin a lokaci ɗaya ana kiransa tsarin shigarwa.Wani lokaci, a cikin wannan tsari, aikin aikin na iya buƙatar shigar da shi sau da yawa don cimma manufa ta ƙarshe.Ya kamata a lura a nan cewa ya kamata a rage yawan adadin shigarwa a cikin aikin sarrafawa, don rage kuskuren shigarwa da kuma adana karin lokaci.

3. Matakin Tsari:

A cikin sassan sarrafa kayan aiki, ƙarƙashin yanayin kayan aiki mara canzawa, saurin gudu da ciyarwa, ci gaba da aiwatar da aiwatar da wannan ɓangaren ana kiransa matakin tsari.Matakin tsari shine ainihin sashin aikin injin;

4. Tashar sarrafawa:

Domin kammala wani tsari, bayan danne lokaci guda, kayan aiki da na'urar da za a iya motsi ta kowane matsayi, misali, tare da kan mai nuna alama don niƙa hexagonal, kowane juyi ana kiransa tashar sarrafawa.

5. Ciyarwa:

A cikin wannan mataki na tsari, idan aikin yana da girma, kana buƙatar amfani da kayan aiki iri ɗaya, a cikin sauri da kuma ciyarwa, a kan kayan aiki guda ɗaya na sau da yawa yankan, kowane yankan ana kiransa abinci.

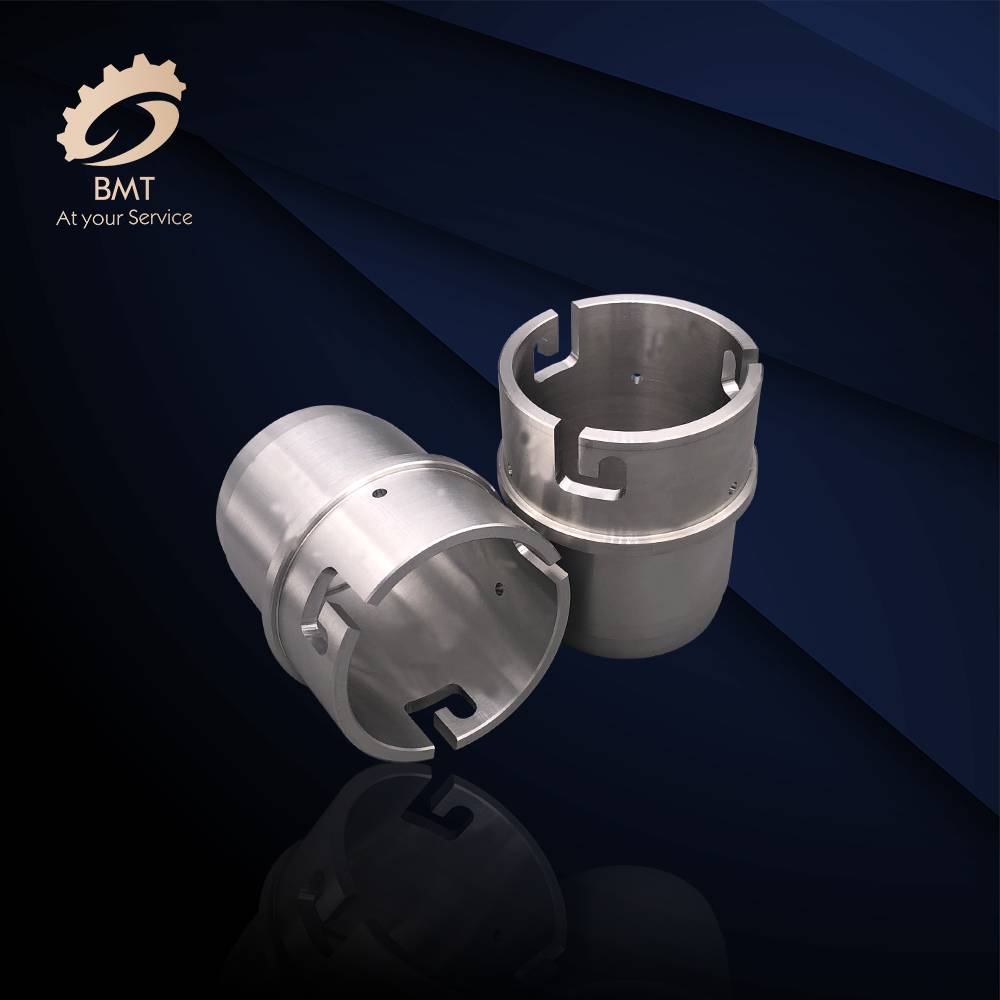

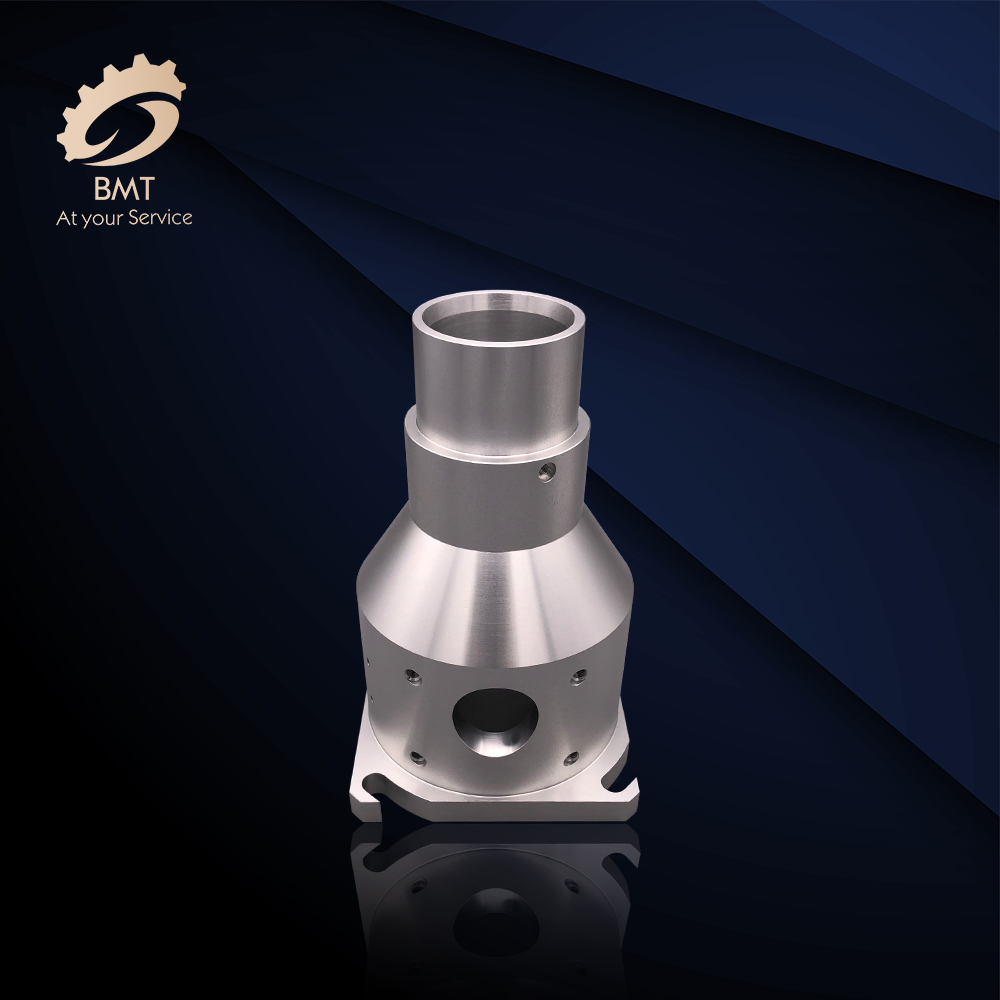

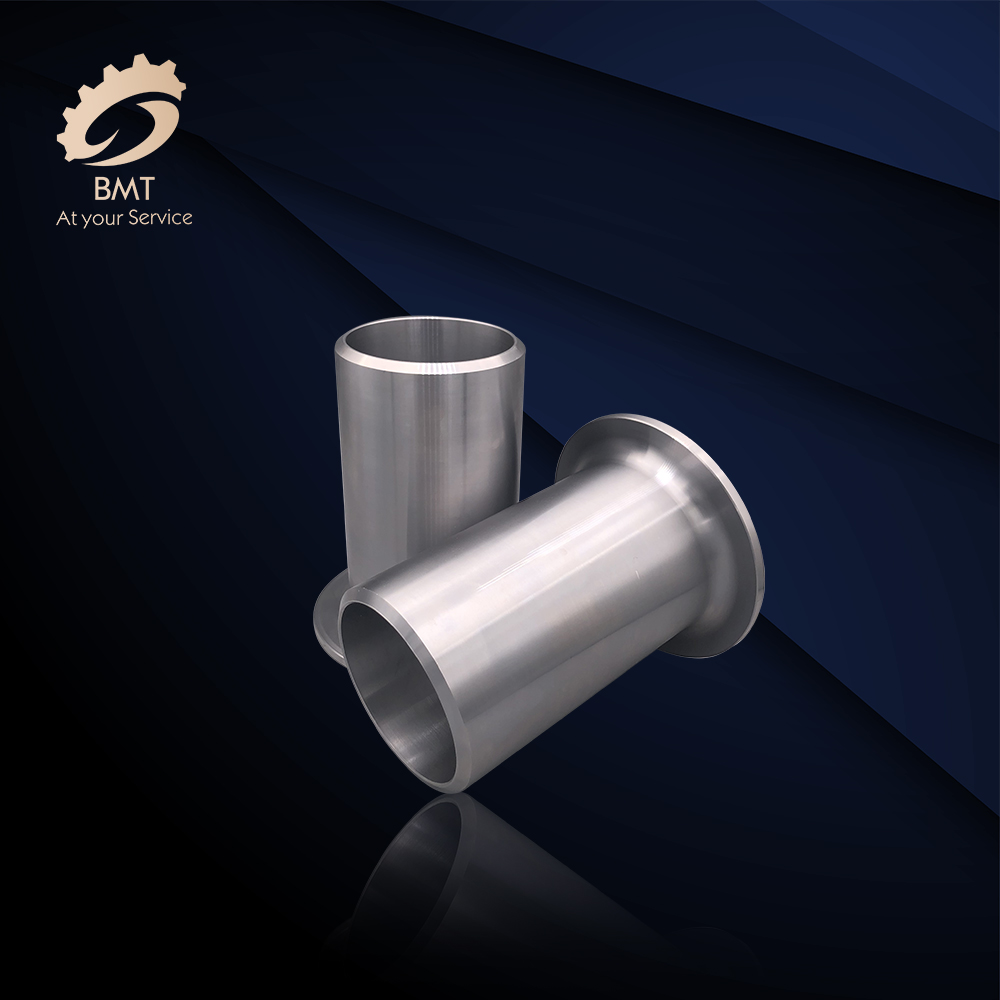

BMT ƙwararrun masana'antun injinan CNC ne, masana'anta sun mallaki injunan sarrafa madaidaicin, samar da CNC, injin injin da sauran ayyuka.

BMT yana da wadataccen gogewa a fagen kera motoci, sararin samaniya, injina, abinci, makamashi, mai, aikin gona, da sauransu, muna karɓar sassan sassa na al'ada kuma muna maraba da ku ga kowane shawarwari.