Abubuwan Da Suke Tasirin Ruɗin Sashe

- Girman Sashe

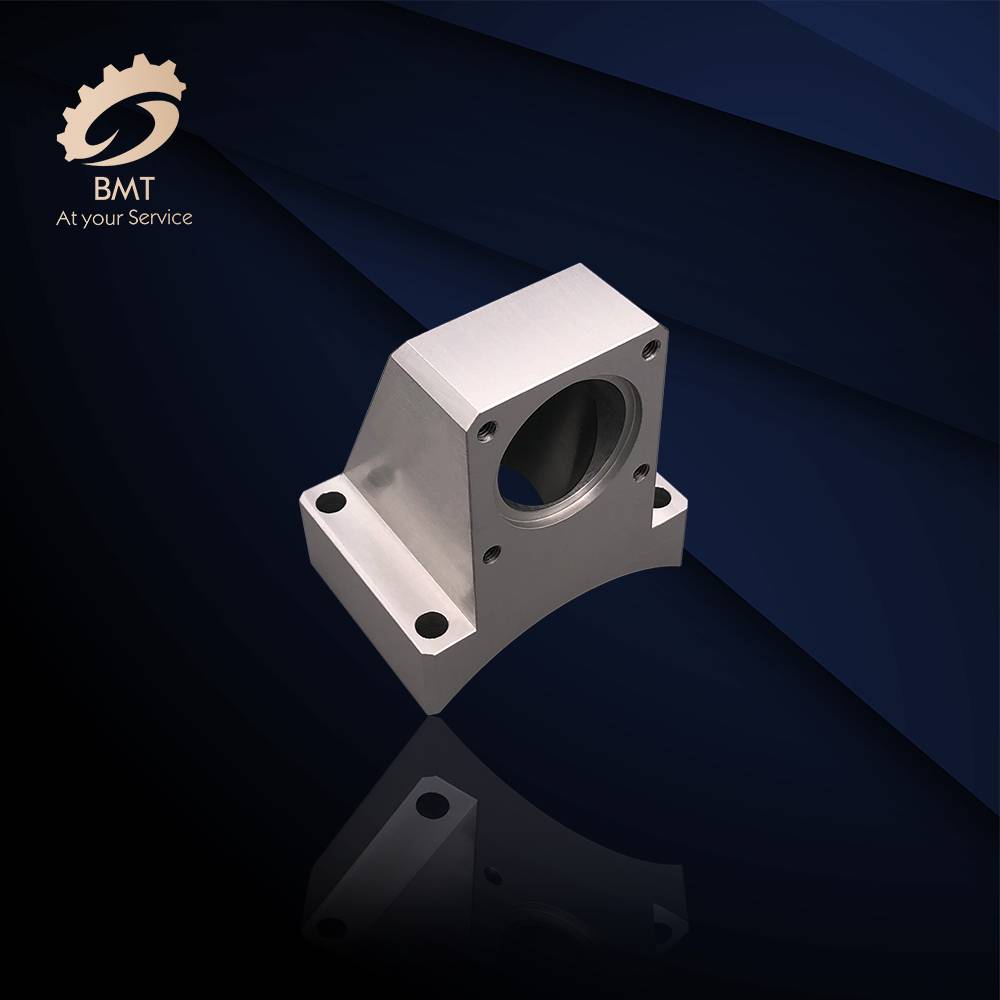

Girman kawai ba ya ƙayyade ƙayyadaddun ɓangaren ba, amma yana iya zama dalili.Yi la'akari, lokaci-lokaci manyan sassan shirin ba su da ƙalubale fiye da ƙananan sassa masu rikitarwa.Har ila yau, la'akari da girman nau'in siffofi na mutum, saboda wannan yana rinjayar girman kayan aikin yanke wanda za a yi amfani da shi.Mafi girma, kayan aiki mai saurin sauri zai iya cire kayan aiki da sauri, rage lokacin mashin.

- Sarrafa sashi

Adadin ayyuka, shiga tsakani da bincike da ake buƙata a ɓangaren kuma za su yi tasiri ga rikitarwar ɓangaren.Dangane da lissafin lissafi, ƙarewa da haƙuri da sauransu, tsarin ayyuka na iya zama mai rikitarwa, mai cin lokaci da daki-daki.Misali, wani sashe mai sarkakkiya na iya buqatar sauye-sauye da yawa da sa hannun hannu.Lokaci-lokaci, injin axis 5 ko injin juyi na iya zama na'ura mafi dacewa, misali, idan yana da tsada don samarwa ko yana buƙatar ƙarancin farashi.

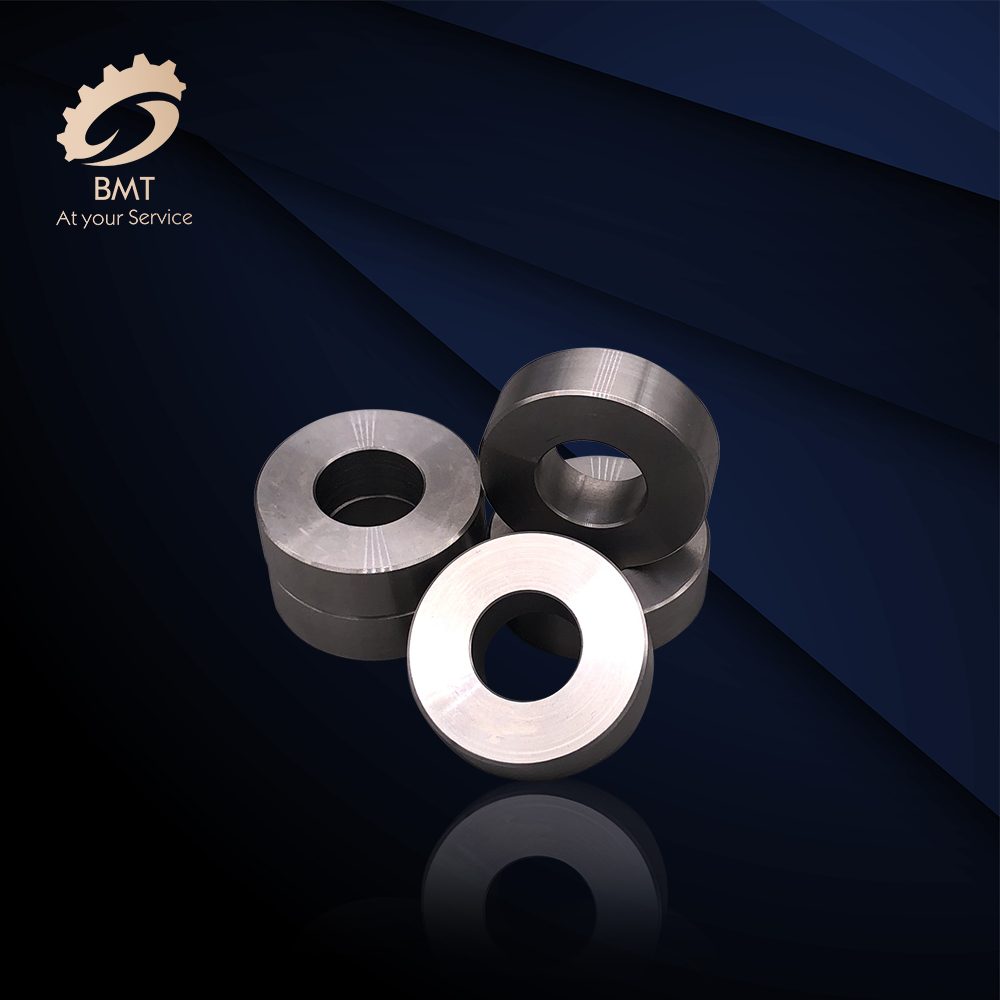

- Haƙuri sashi

Haƙurin ɓangaren na iya yin tasiri ga zaɓin injin CNC da aka yi amfani da shi kuma yana iya shafar farashi da lokacin jagora.Haƙurin da za a iya cimmawa kuma yana tasiri ta kayan aiki, saurin injina da kayan aiki.A taƙaice, ƙara ƙarfin haƙuri, ƙarin ɓangaren ku zai biya.Haƙuri mafi girma yana ba da damar ƙarin daidaito, amma kuma yana iya haɗawa da ƙarin matakai, ayyuka, da kayan aiki da injuna, don haka ƙara farashi.

Nau'in gamawa

- Ƙwaƙwalwar ƙaya

Bead blasting ya ƙunshi cire kowane adibas ko ajizanci a ɓangaren ɓangaren don sutura mai kyau, gamsarwa.Beads masu siffar sphere suna tabbatar da daidaiton ƙarewa kuma ana amfani da su don ba da ƙare matt.Hakanan za'a iya amfani da beads masu kyau don ƙarin satin-kamar ƙare ko maras kyau.

- Anodized ya ƙare

Ƙarshen Anodized yana ba da ƙayyadadden shafi mai jure lalacewa, yawanci ana samun su cikin launuka masu yawa.Anodizing gabaɗaya m, kuma Layer yawanci bakin ciki ne don haka tabbatar da la'akari da alamun CNC Machine akan saman.

- Kamar yadda mashin

Wani gamawa zai bar tarkacen saman yayin da ake sarrafa yanki.Ana ƙayyade ainihin ƙarancin sabis ta amfani da ƙimar Ra.Yawanci ƙarancin ƙasa don sassan injinan CNC shine Ra 1.6-3.2µm.

Rahoton Binciken CMM

Menene rahoton CMM kuma me yasa nake buƙatar ɗaya?

Binciken Injin Auna Daidaitawa (CMM) ya ƙunshi amfani da na'ura mai daidaitawa don duba girman ɓangaren don tabbatar da ko wani ɓangaren ya cika takamaiman buƙatun haƙuri.Ana amfani da na'ura mai aunawa don auna inganci da halayen abu.

Za a buƙaci binciken CMM don auna sassa masu rikitarwa don tabbatar da sun dace da ƙayyadaddun bayanai.Sau da yawa za a haɗa su don ɓangarorin madaidaicin madaidaicin inda ake buƙatar ingantaccen inganci da daidaito.A wannan lokaci, za a kuma bincika abubuwan da aka gama sumul don tabbatar da cewa sun dace da zane da ƙira.

CMM yana aiki ta amfani da bincike wanda ke auna maki akan kayan aiki.3 gatari suna samar da tsarin daidaita mashin ɗin.Sauran tsarin shine tsarin haɗin kai, inda gatura 3 ke da alaƙa / dacewa da fasali da bayanan aikin aikin.

Amfanin Binciken CMM

Za a gudanar da binciken CMM kamar yadda kuma lokacin da ake buƙata, kuma wani lokaci zai zama tilas.Rahoton binciken CMM na iya adana lokaci da rage yawan kuɗin da ake kashewa ta hanyar tabbatar da cewa ɓangaren an ƙera shi daidai da ƙira.Wannan yana tabbatar da cewa babu wani abu da aka bari ga kwatsam kuma ana samun kowane sabani daga ƙira ko kuskure kafin jigilar kaya.

Dangane da masana'antar, ƙetare ƙayyadaddun ƙayyadaddun bayanai na iya zama bala'i (Misali, masana'antar likitanci, ko masana'antar sararin samaniya.) Wannan duban ingancin inganci na ƙarshe zai iya ba da tabbaci kafin a kashe ɓangaren kuma a kai ga abokin ciniki.