BMT CNC Machining Services Capabilities

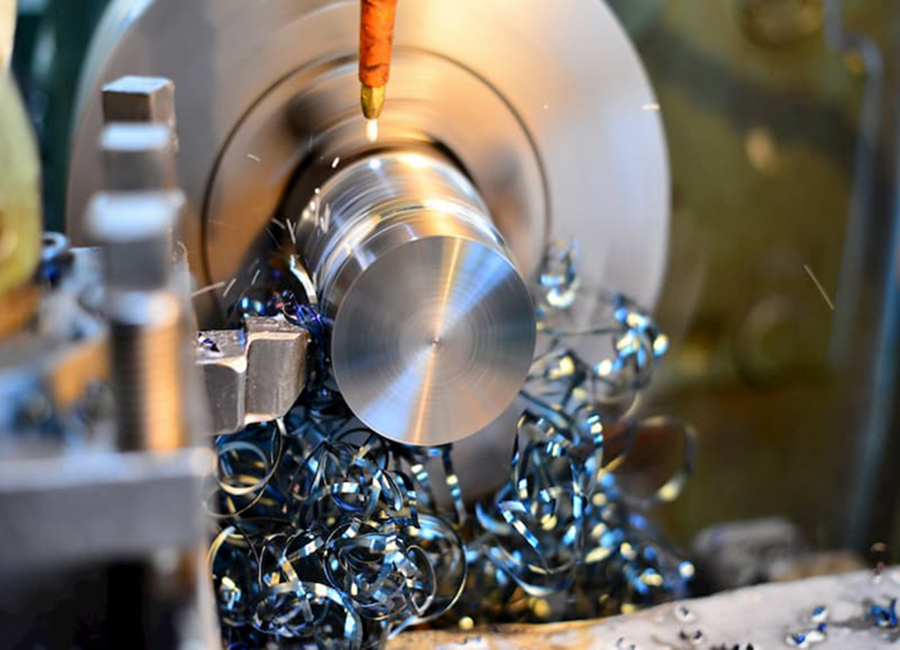

A matsayin ɗaya daga cikin masu samar da mashin ɗin CNC mafi saurin girma, BMT yana cikin Kasuwanci don Manufa ɗaya.don Magance Matsalolin Samar da Saurin Juyi.Wadannan manyan damar injina a BMT suna samuwa don biyan buƙatun ku na CNC MACHINED PARTS, kama daga saurin samfuri zuwa madaidaicin sassa da injinan kayan aiki, da samar da ƙarshen amfani.

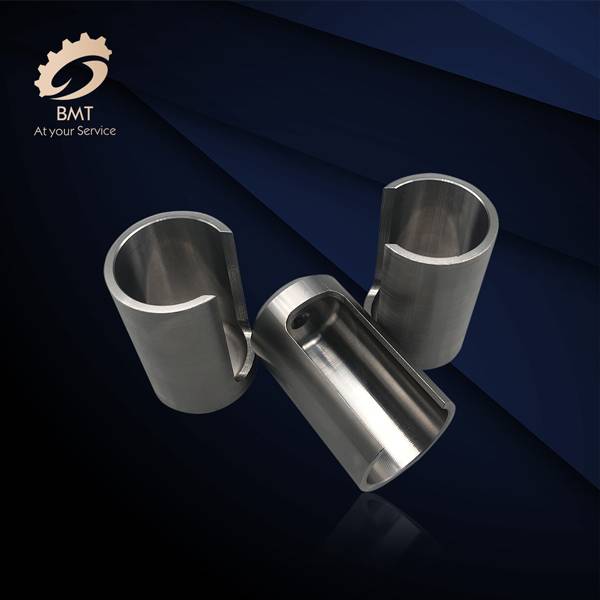

CNC Juya:Wani tsari na masana'anta wanda aka gudanar da sanduna na abu a cikin chuck da juyawa yayin da aka yi amfani da kayan aiki, tare da kayan aiki na yanke don cire kayan aiki don ƙirƙirar siffar da ake so.Ko, za mu iya cewa fasahar ta hanyar abin da block abu gyarawa a kan CNC juya cibiyar ko lathe juyawa tare da babban gudun, yayin da yankan kayan aiki motsi a cikin juyawa axis don aiwatar da workpiece, don samun CNC juya sassa tare da ainihin zane masu girma dabam.

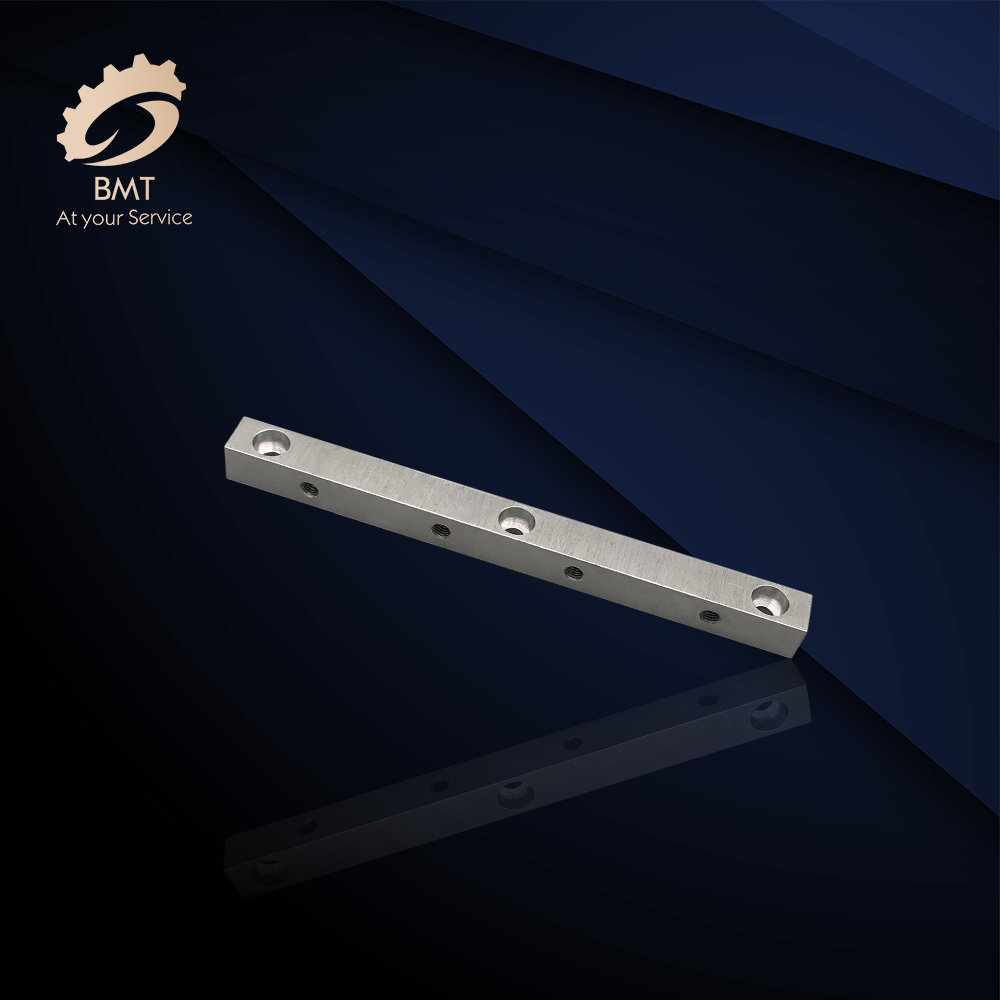

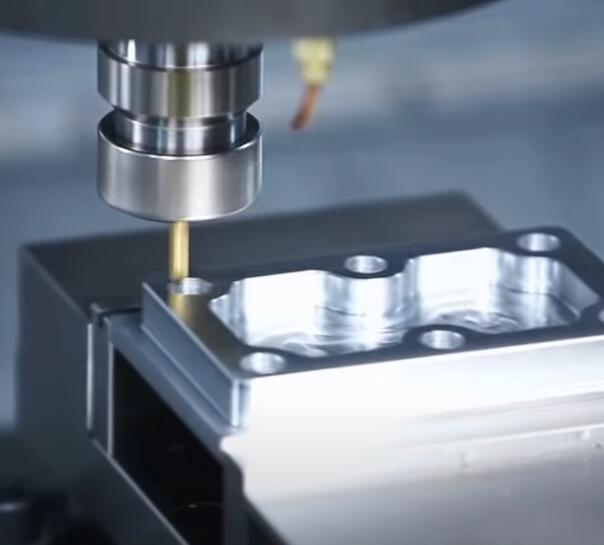

CNC Milling:Mafi na kowa machining tsari wanda utilizes kwamfuta controls da kuma juyawa Multi-point yankan kayan aikin cire abu daga workpiece da kuma samun al'ada tsara samfurin duk lokacin da wasu ƙirƙira hanyoyin kamar Laser yankan ko plasma yankan iya samun guda sakamakon;mutane sun gwammace su zabi mai rahusa.Amma waɗannan hanyoyin ba za su iya kwatanta su da ƙarfin CNC milling ba.Ana amfani da wannan tsari na yau da kullun don sarrafa kayan aiki da yawa, kamar ƙarfe, filastik, gami, tagulla, da dai sauransu Lokacin da injin ɗin ke aiki akan wani yanki mai rikitarwa, mun fi son yin amfani da abin yankan niƙa na CNC don yin motsi madauwari da ƙirƙirar niƙa. sassa masu wasu siffofi, gami da ramummuka, ramuka, tsagi, da sauransu.

CNC hakowa:A yankan tsari da yin amfani da rawar soja yin rami na madauwari giciye-sashe a cikin m abu a cikin abin da workpiece aka gyarawa a kan lathes, niƙa ko hakowa inji da rawar soja bit yawanci Rotary sabon kayan aiki;mai yankan zai kasance daidai da tsakiyar rami kuma ya juya don yin ramukan zagaye.Ana yin aikin hakowa ta hanyar matsar da ɗigon ramin cikin rami tare da gajerun motsi da aka maimaita da sauri.CNC Drilling yana da fa'idodi masu zuwa: daidaito mara daidaituwa tare da haɓaka yawan aiki, rage kashe kuɗi da ingantattun layin samarwa;versatility da reproducibility.

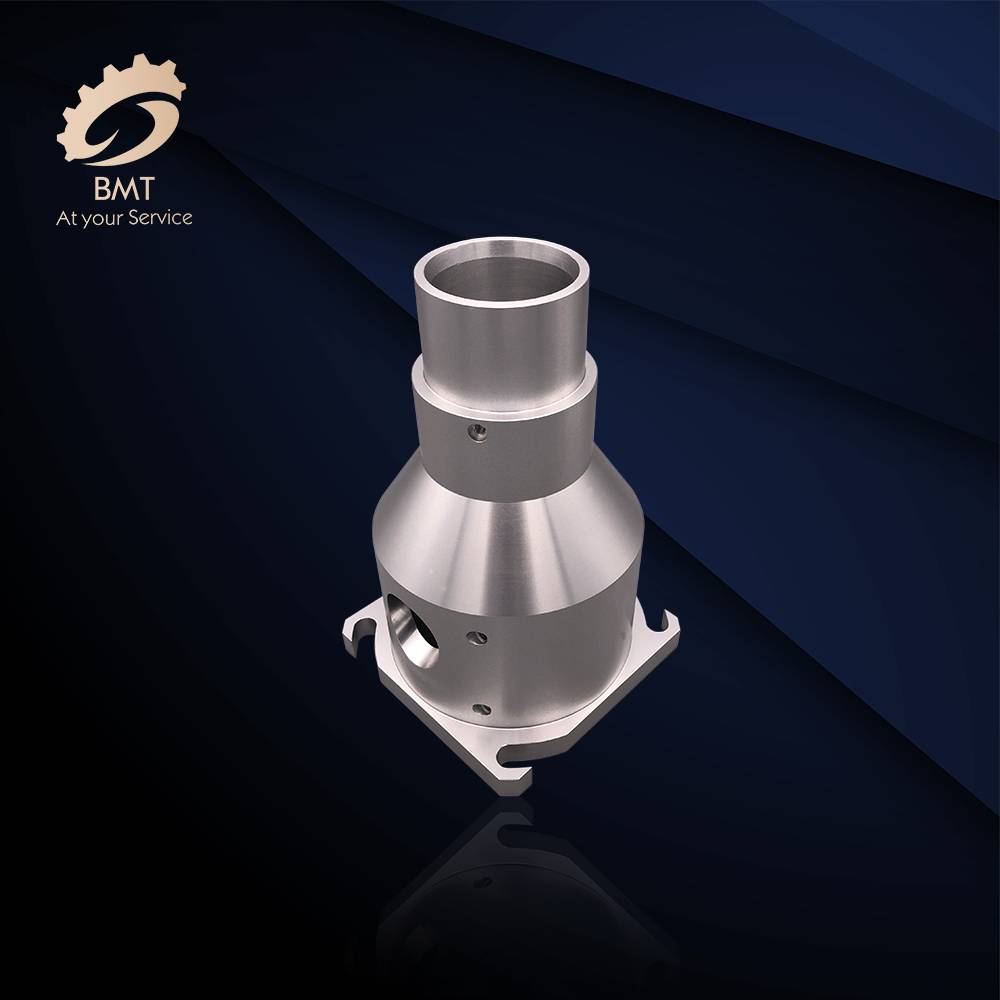

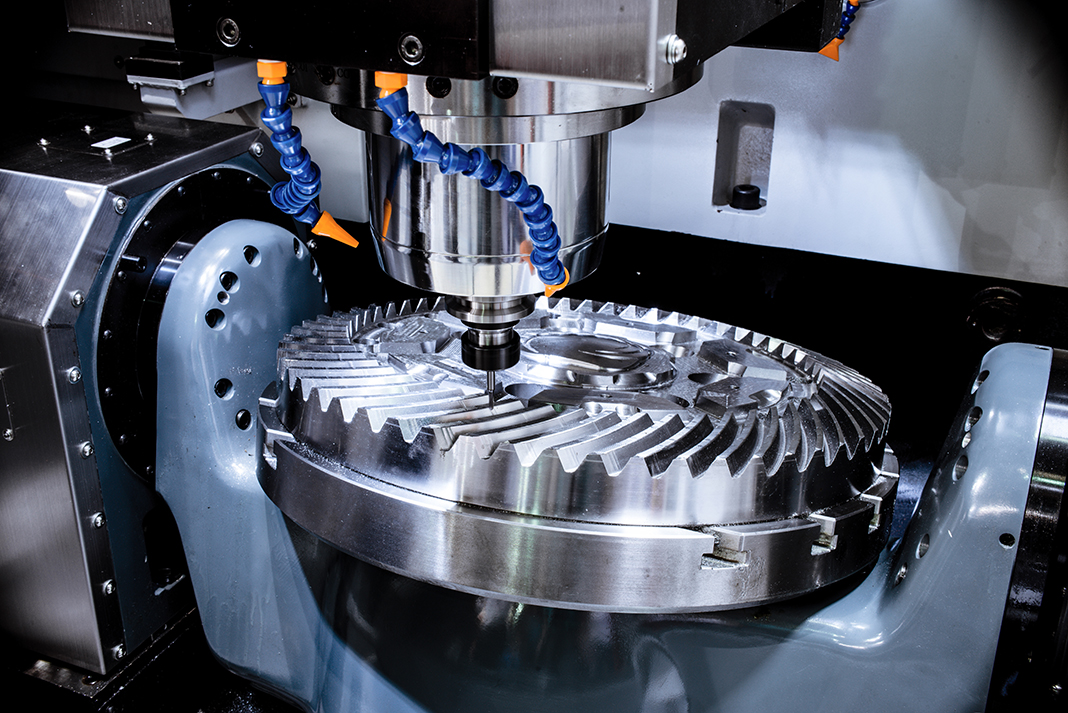

CNC Milling da Juyawa:A al'ada, juyawa da niƙa matakai ne na gama gari guda biyu waɗanda ke cire kayan aiki daga kayan aiki tare da taimakon kayan aikin yankan.Zuwa wani ɗan lokaci, lokacin da aka haɗa niƙa da juyawa tare, an ƙirƙiri ci-gaba CNC Milling da Juyawa.Fasaha ce mai haɗaɗɗiya wacce kayan aikin yankan da kayan aiki duka suna juyawa ta hanyar saitin shirye-shirye a cikin tsarin sarrafa lambobi na kwamfuta, don samar da hadaddun sassa masu lankwasa ko siffa ta musamman ta ƙera nau'ikan ayyuka da yawa.Tare da wannan fasaha ta fasaha mai zurfi, dukkanin sassa masu rikitarwa za su kasance cikin sauƙi ta hanyar shirye-shirye daban-daban.

Bayanin Samfura