Titanium Alloy Mechanical Properties

Titanium alloy yana da ƙarfi mai ƙarfi da ƙarancin ƙima, kyawawan kaddarorin injiniyoyi, tauri mai kyau da juriya na lalata. Bugu da kari, titanium gami aiwatar yi ba shi da kyau, yankan wuya, a cikin zafi aiki, sosai sauki sha hydrogen oxygen nitrogen carbon da sauran impurities. Akwai juriya mara kyau, tsarin samarwa mai rikitarwa. An fara samar da titanium na masana'antu a cikin 1948. Ci gaban masana'antar sufurin jiragen sama ya buƙaci, ta yadda masana'antar titanium tare da matsakaicin haɓakar haɓakar shekara-shekara na kusan kashi 8%.

A halin yanzu, abin da ake fitarwa a duk shekara na titanium gami a duniya ya kai fiye da ton 40,000, kuma kusan nau'ikan titanium alloy iri 30. Mafi yadu amfani titanium gami ne Ti-6Al-4V(TC4),Ti-5Al-2.5Sn(TA7) da kuma masana'antu tsarki titanium (TA1, TA2 da TA3).

Ana amfani da allunan Titanium don kera sassan injinan jirgin sama, sai kuma sassan tsarin na rokoki, makamai masu linzami da kuma jiragen sama masu sauri. A tsakiyar shekarun 1960, an yi amfani da titanium da kayan haɗin gwiwarsa a masana'antu gabaɗaya don kera na'urorin lantarki don electrolysis, na'urorin kwantar da wutar lantarki, masu dumama don tace mai da tsabtacewa, da na'urorin sarrafa gurɓataccen ruwa. Titanium da kayan haɗin gwiwarsa sun zama nau'in lalata - kayan gini masu juriya. Bugu da ƙari, ana amfani da ita don samar da kayan ajiya na hydrogen da sifofin ƙwaƙwalwar ajiya.

A shekarar 1956, kasar Sin ta fara gudanar da bincike kan sinadarin titanium da titanium; A tsakiyar shekarun 1960, an fara samar da kayan aikin titanium na masana'antu da haɓakar TB2 gami. Titanium alloy wani sabon muhimmin abu ne na tsarin da ake amfani da shi a masana'antar sararin samaniya. Ƙarfinsa na musamman, ƙarfinsa da zafin sabis yana tsakanin aluminum da karfe, amma ƙayyadaddun ƙarfinsa yana da girma kuma yana da kyakkyawan lalatawar ruwan teku da ƙananan zafin jiki.

A shekara ta 1950, an fara amfani da jirgin F-84 mai bama-bamai a matsayin garkuwar zafi na baya, murfin iska, murfin wutsiya, da sauran abubuwan da ba su da ƙarfi. Tun daga shekarun 1960, an motsa yin amfani da gami na titanium daga fuselage na baya zuwa tsakiyar fuselage, wani sashi na maye gurbin tsarin karfe don yin mahimman abubuwan haɓaka kamar firam, katako da zamewar flap. Amfani da titanium gami a cikin jirgin sama na soja ya karu da sauri, ya kai 20% ~ 25% na nauyin tsarin jirgin.

Aiko mana da sakon ku:

-

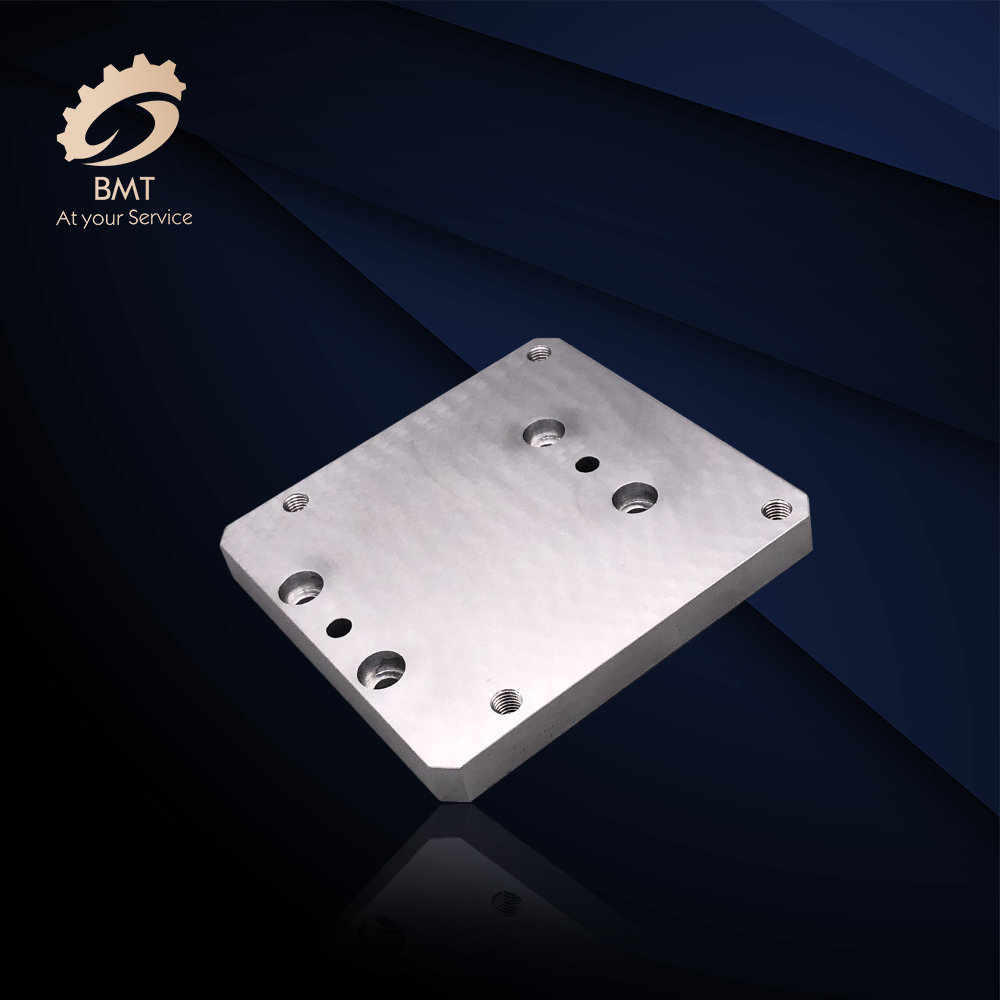

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes