Bayanin Tsarin Mashin ɗin CNC

Da yake magana game da tsarin sarrafa ma'auni na ƙididdigewa, tsari ne na masana'antu wanda ke amfani da sarrafa kwamfuta don yin amfani da CNC Machines da kayan aikin yanke don samun sassan da aka tsara tare da karafa, robobi, itace ko kumfa, da dai sauransu. mahimman ka'idodin tsari iri ɗaya ne.Babban tsarin injin CNC ya haɗa da:

▶ Zane ta CAD;

▶ Mayar da CAD zuwa Shirin CNC;

▶ Shigar da shirin a cikin Injin CNC;

▶ Gudanar da aikin injin;

▶ Samun abubuwan da aka tsara.

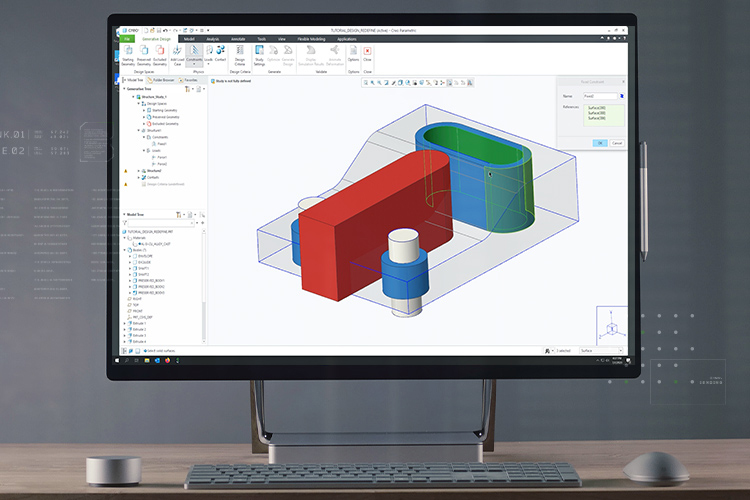

Zane ta CAD

Tsarin mashin ɗin CNC yana farawa da software na 2D ko 3D waɗanda ƙwararrun masu ƙira suka yi.CAD, Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwararren Ƙwaƙwalwa na Ƙadda ) ya yi, ya ba da damar masu ƙira da masana'antun su samar da samfurin sassan su bisa ga ƙayyadaddun fasaha, ciki har da girma, buƙatun fasaha da bayanan masu zanen kaya.Zayyana na CNC Machined Parts an iyakance ta da damar CNC Machines da Yankan kayan aiki, da aikace-aikace na workpieces.Misali, yawancin kayan aikin CNC Machine suna da silindi, sabili da haka, ɓangaren da aka tsara geometries yana iyakance yayin da kayan aikin ke haifar da sasanninta.Bugu da kari, kaddarorin kayan, kayan aikin injin da kuma damar rike injina suna iyakance damar nadi, kamar mafi ƙarancin kauri, matsakaicin girman sassa, da fasalulluka na ciki, da sauransu.

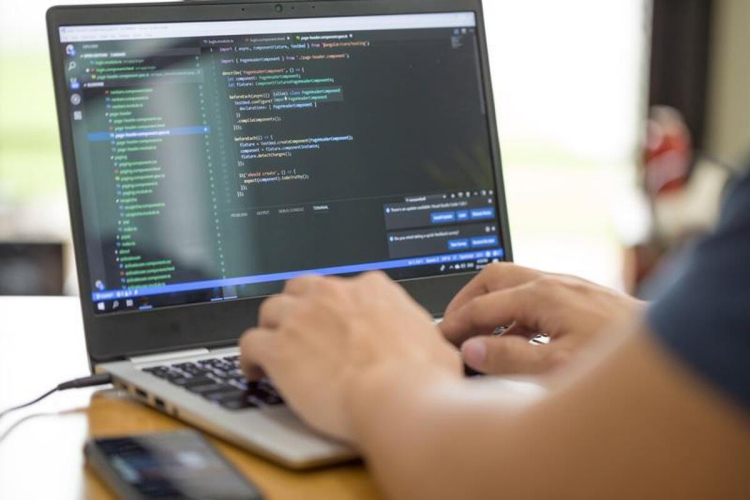

Cjuya CAD zuwa Shirin CNC

Da zarar an gama ƙirar CAD, mai ƙira yana shigar da shi zuwa fayil ɗin STEP.Fayilolin ƙirar CAD suna aiki ta hanyar shirin don cire sassan geometries kuma suna haifar da lambar shirye-shiryen da za ta sarrafa injina da kayan aiki don samar da sassan da aka tsara na al'ada.Injin CNC suna amfani da yarukan shirye-shirye da yawa, kamar G-code da M-code.G-code shine yaren shirye-shiryen da aka fi sani, wanda ke sarrafa lokacin, a ina da kuma yadda kayan aikin injin ke motsawa, misali, lokacin da na'ura ta kunna ko kashewa, saurin tafiya zuwa wani wuri, hanyoyin da za a bi, da dai sauransu. M-code yana sarrafa ayyukan taimako na inji, kamar cirewa ko maye gurbin murfin injin lokacin da ake buƙata ta atomatik.Da zarar an samar da shirin CNC, mai aiki yana loda shi zuwa injin CNC.

Saita Injin

Kafin mai aiki ya gudanar da shirin CNC, dole ne su shirya na'urar CNC don aiki.Waɗannan shirye-shiryen sun haɗa da gyara kayan aikin akan injin, daidaita mashin ɗin injin da kayan aikin injin.Haɗa kayan aikin da ake buƙata, irin su ƙwanƙwasa ƙwanƙwasa da injina na ƙarshe, zuwa kayan aikin injin da ya dace.Da zarar an gama saita na'ura, mai aiki zai iya tafiyar da shirin CNC.

Aikin Kisa na Machining

A matsayin umarnin na'urar CNC, shirin CNC yana ƙaddamar da umarnin kayan aiki da motsi zuwa kwamfutar da aka haɗa ta na'ura, wacce ke aiki da sarrafa kayan aikin injin don yin aiki akan kayan aikin.Shirye-shiryen farawa yana nufin injin CNC yana fara aiwatar da mashin ɗin, kuma shirin yana jagorantar injin a duk lokacin da ake aiwatar da shi don samar da wani ɓangaren da aka ƙera.CNC machining tafiyar matakai za a iya kashe a cikin gida idan kamfanin yana da nasu kayan aikin CNC-ko fita-sourced zuwa sadaukar CNC machining masu samar da sabis.

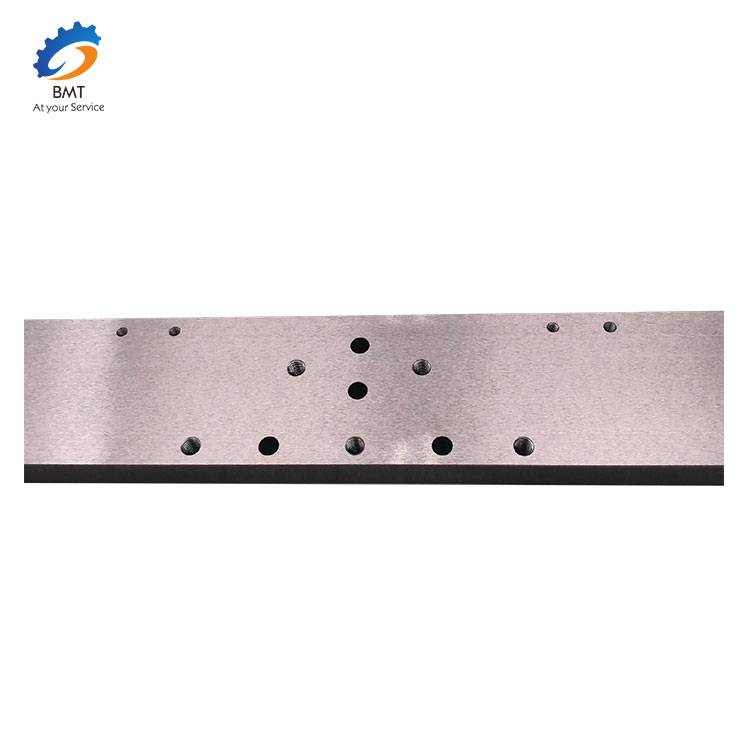

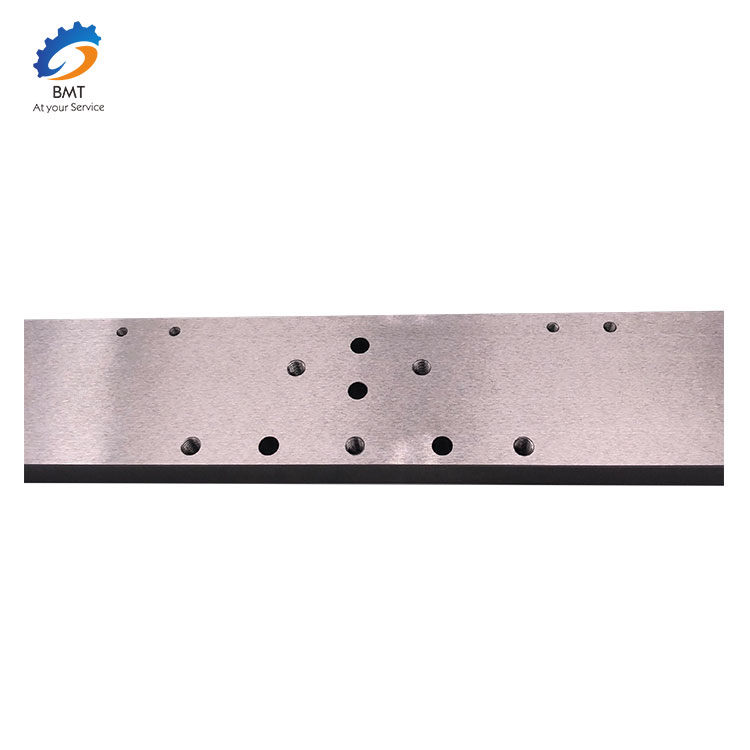

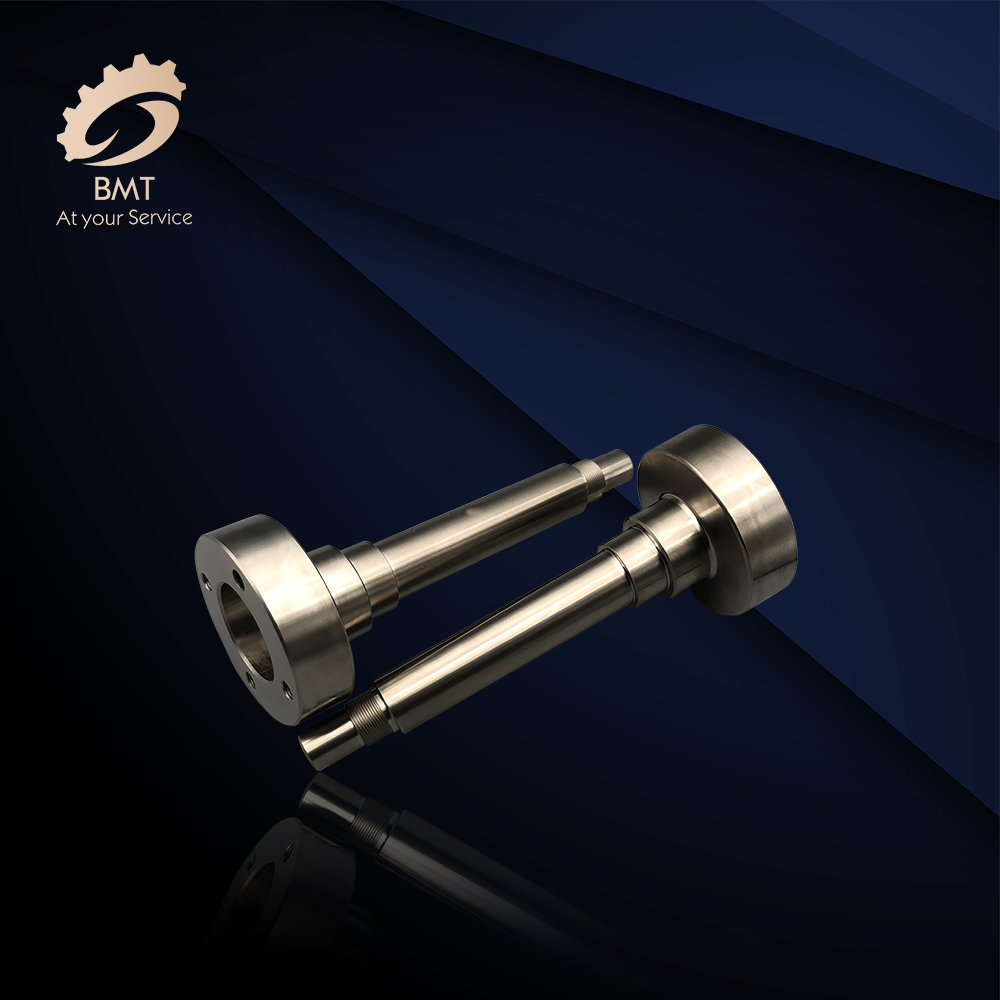

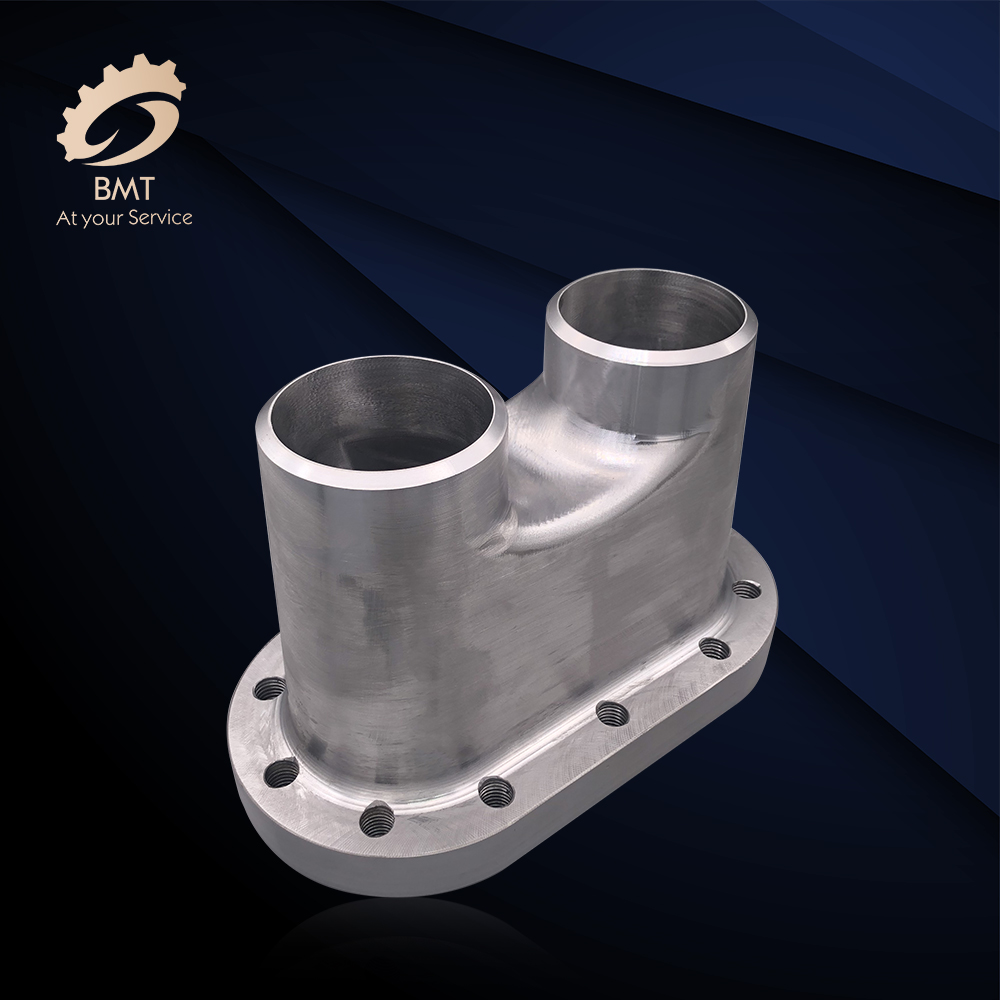

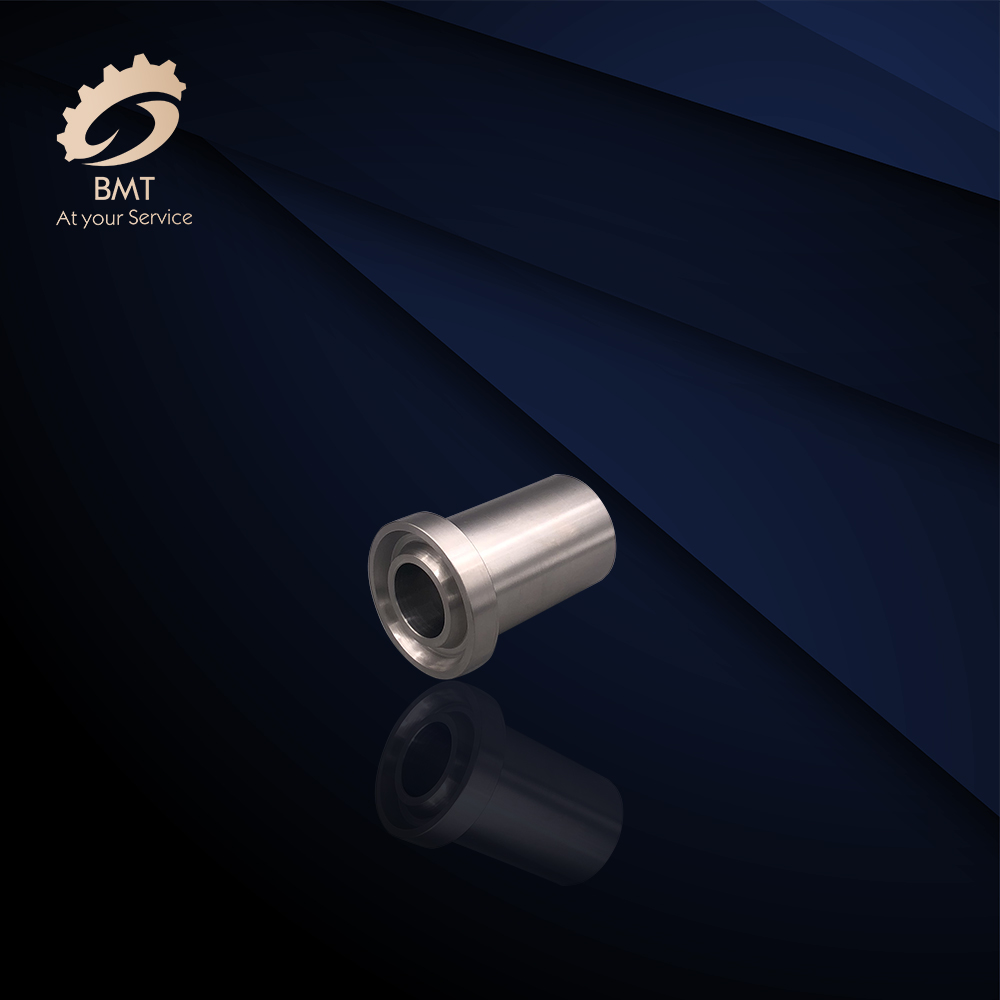

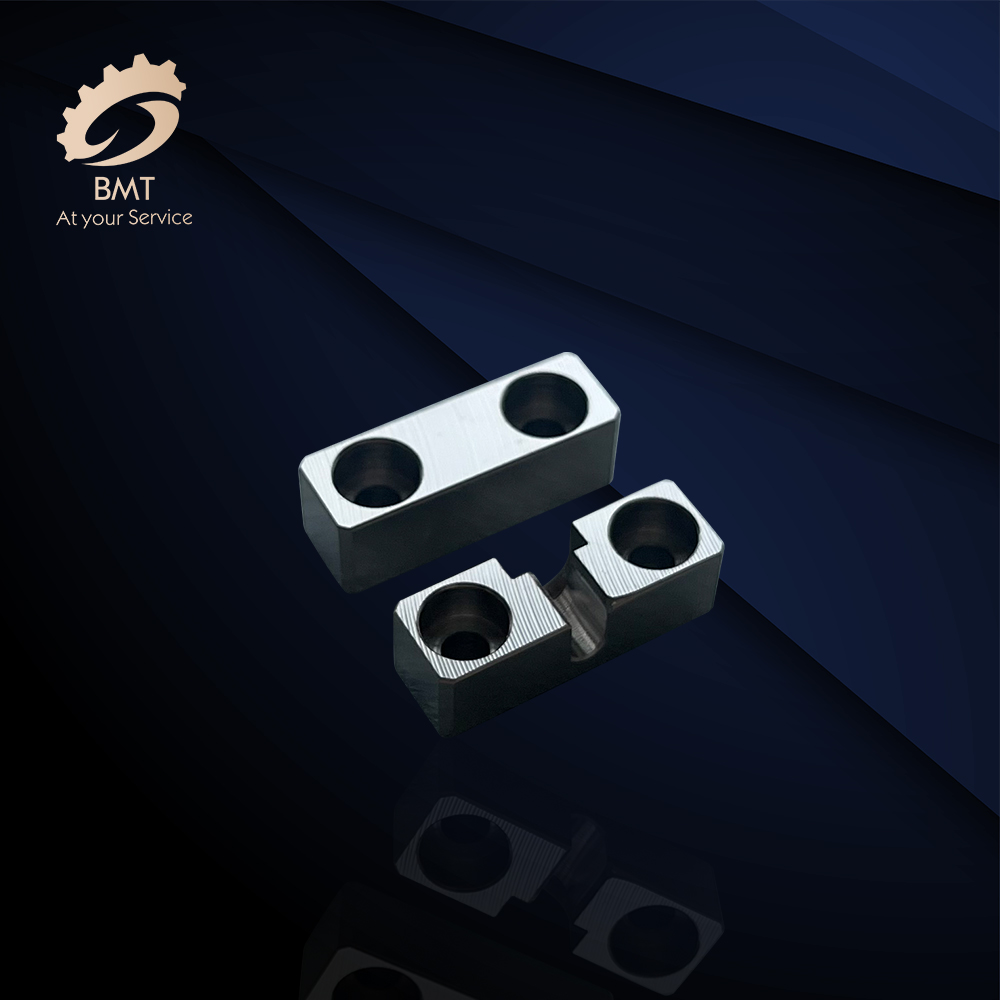

Mu, BMT, ne mai kwazo CNC machining sabis manufacturer, tsunduma a samar high daidaici machined sassa ga masana'antu na Automotive, Abinci Processing, Masana'antu, Man Fetur, Energy, Aviation, Aerospace, da dai sauransu tare da m tolerances da high daidaici.A zahiri muna kula da abin da kuke buƙata da sadaukarwa don samar da mafi kyawun sabis na injina da sassa zuwa buƙatun masana'anta da sauri.