Nau'in Injin Injiniya

Babban Rabewa

Akwai manyan nau'ikan injina guda biyu: injina na hannu da injinan CNC.Yin aiki da hannu yana nufin hanyar sarrafa abubuwa daban-daban ta hanyar sarrafa kayan aikin injina da hannu kamar injin niƙa, lathes, injin hakowa da injinan yanka na ma'aikatan injina.Kayan aikin hannu ya dace da ƙananan ƙarami, samar da sassa mai sauƙi.CNC machining (CNC) yana nufin yin amfani da kayan aikin CNC ta ma'aikatan injiniya don sarrafawa.Wadannan kayan aikin CNC sun haɗa da cibiyoyin injin, juyawa da wuraren niƙa, kayan aikin EDM na waya, na'urorin yankan zare, da sauransu.Ta hanyar shirye-shirye, masu daidaita matsayi (X, Y, Z) na workpiece a cikin tsarin haɗin gwiwar Cartesian ana canza su zuwa harshen shirye-shirye.

Mai kula da CNC na kayan aikin injin CNC yana sarrafa axis na kayan aikin injin CNC ta hanyar ganowa da fassarar harshen shirye-shirye, kuma ta atomatik cire kayan kamar yadda ake buƙata., don samun ƙãre workpiece.CNC machining tafiyar matakai workpieces a ci gaba da kuma dace da babban yawa na sassa da hadaddun siffofi.

Fasahar Gudanarwa

Taron bitar na iya amfani da tsarin CAD/CAM (Computer Aid Design Computer Aid Manufacturing) don tsara kayan aikin injin CNC ta atomatik.Geometry na ɓangaren ana canjawa wuri ta atomatik daga tsarin CAD zuwa tsarin CAM, kuma mashin ɗin yana zaɓar hanyoyin mashin ɗin daban-daban akan nuni mai kama-da-wane.Lokacin da mashin ɗin ya zaɓi wata hanyar mashin ɗin, tsarin CAD / CAM na iya fitar da lambar CNC ta atomatik, galibi ana kiranta lambar G, kuma shigar da lambar a cikin mai sarrafa kayan injin CNC don ainihin ayyukan injin.

Sauran Kayan aiki

Kayayyakin da ke bayan masana'anta, kamar na'urorin yankan karfe (ciki har da juyi, niƙa, tsarawa, sakawa da sauran kayan aiki), idan sassan na'urorin da ake buƙata don samarwa sun karye kuma suna buƙatar gyara, suna buƙatar tura su zuwa injin ɗin. bita don gyara ko sarrafawa.Domin tabbatar da ci gaba mai kyau na samarwa, kamfanoni na gabaɗaya suna da taron bita, waɗanda ke da alhakin kula da kayan aikin samarwa.

Hanyoyin Aiki

I. Bayani

Wannan tsarin aiki yana yin ƙayyadaddun umarni da cikakkun bayanai ga duk ma'aikatan da ke aiki da injina don tabbatar da ingancin kowane ɓangaren injina.

2. Iyakar aikace-aikace

Wannan ƙa'ida ta ƙididdige takamaiman ayyukan ma'aikatan injuna (ciki har da juyawa, niƙa, hakowa, tsarawa, niƙa, shear, da sauransu) yayin aiki.

3. Gabaɗaya dokoki

Dole ne a gudanar da aikin injina daidai da wannan ka'ida yayin sarrafa sassan injin daban-daban.

Aiko mana da sakon ku:

-

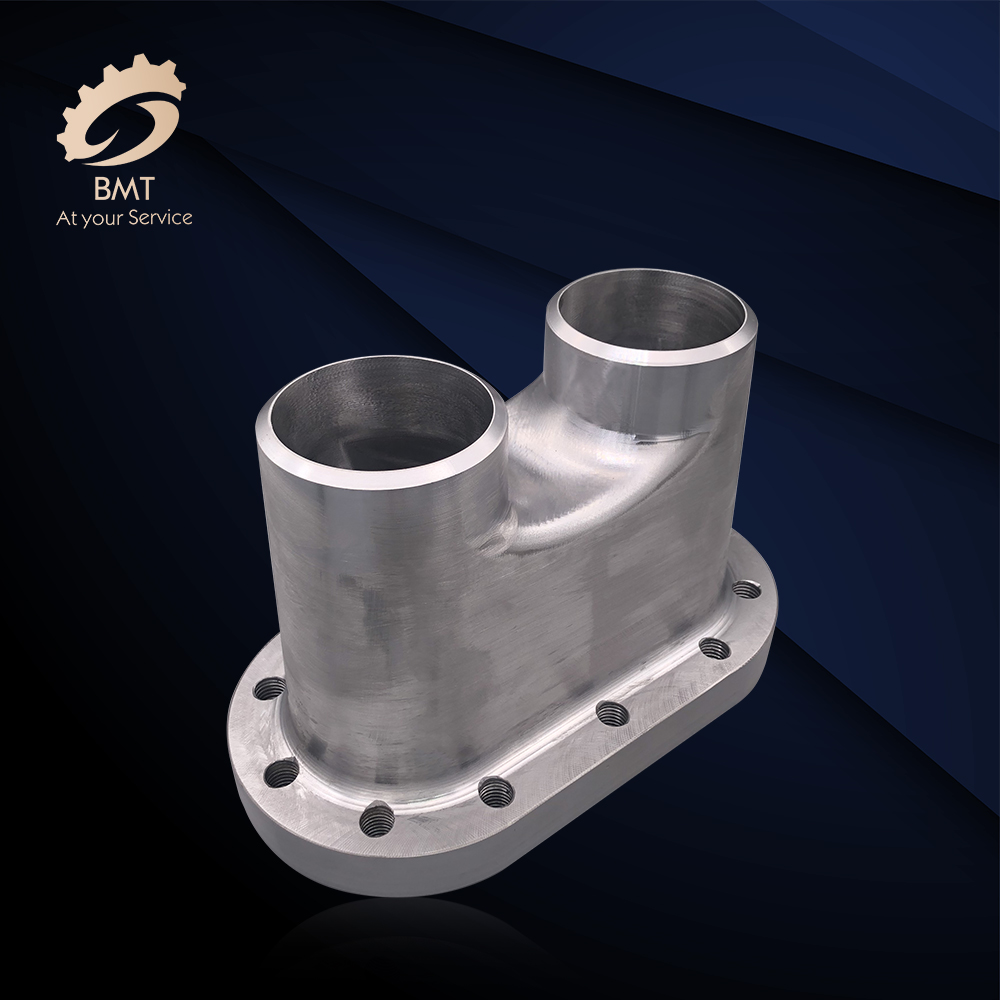

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes