Titanium Alloy CNC Machining

Lokacin da taurin titanium gami ya fi HB350, yankan yana da wahala musamman, kuma lokacin da bai kai HB300 ba, yana da sauƙin mannewa wuka kuma yana da wuya a yanke. Saboda haka, ana iya magance matsalar sarrafa titanium daga ruwa. Rashin lalacewa na saka tsagi a cikin machining na titanium alloys shine lalacewa na gida na baya da gaba a cikin zurfin yanke, wanda sau da yawa yakan haifar da taurin Layer da aka bari ta baya.

Halin sinadarai da yaduwar kayan aiki da kayan aikin aiki a yanayin aiki sama da 800 ° C suma suna daya daga cikin dalilan samuwar tsagi. Domin a lokacin da machining tsari, da titanium kwayoyin na workpiece tara a gaban ruwa da aka "welded" zuwa ruwa gefen karkashin high matsa lamba da kuma high zafin jiki, forming wani gina-up gefen.

Lokacin da gefen da aka gina shi ya cire gefen yanke, yana cire murfin carbide na abin da aka saka, don haka aikin titanium yana buƙatar kayan sakawa na musamman da geometries.

.

Ya kamata a ambata cewa tun lokacin da aka yi amfani da kayan aikin titanium suna haifar da zafi mai zafi a lokacin aiki, dole ne a fesa babban adadin ruwa mai mahimmanci a kan yanke a cikin lokaci da kuma daidai don cire zafi da sauri. Har ila yau, akwai sifofi na musamman na masu yankan niƙa waɗanda aka yi amfani da su musamman don sarrafa gami da titanium a kasuwa a yau, waɗanda suka fi dacewa da sarrafa gami da titanium.

A halin yanzu, duk ƙasashe suna haɓaka sabbin kayan aikin titanium tare da ƙarancin farashi da babban aiki, kuma suna ƙoƙarin sanya kayan aikin titanium su shiga fagen masana'antar farar hula tare da babbar kasuwa. kasata kuma ba ta hakura don ci gaba a wannan fanni.

An yi imanin cewa, ta hanyar hadin gwiwa na dukkan kwararrun masana'antu, sarrafa na'urorin titanium ba zai zama matsala a nan gaba ba, amma zai zama wani kaifi mai kaifi ga ci gaban masana'antu na kasata, tare da shawo kan matsalolin da ke haifar da ci gaban masana'antu. dukan masana'antu.

Aiko mana da sakon ku:

-

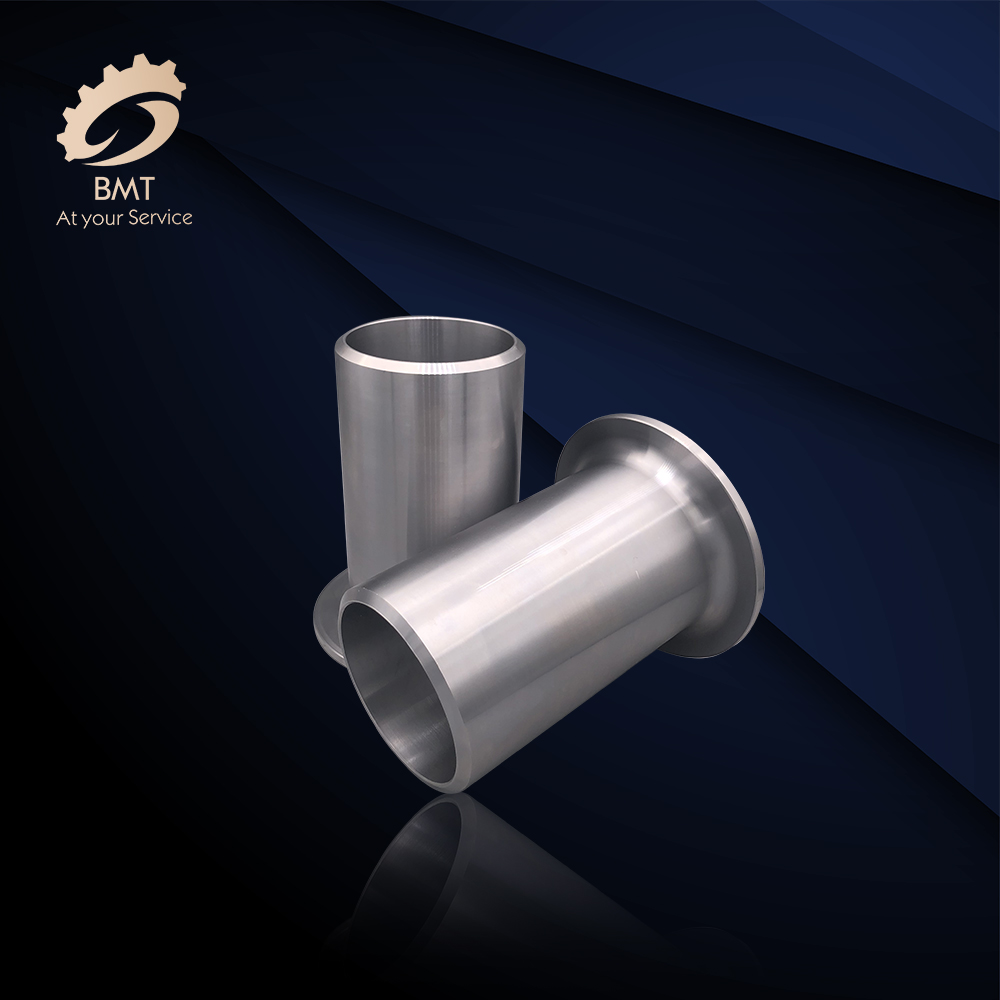

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes