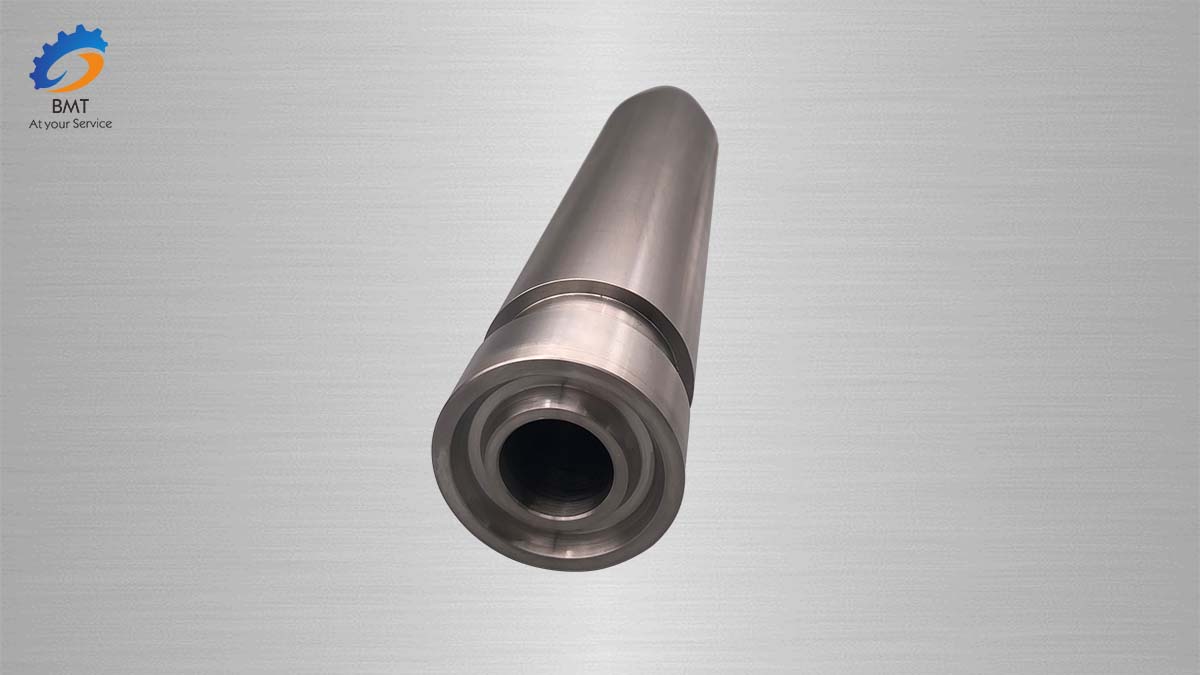

Titanium Alloy CNC Machining

Mashin ɗin matsi na alloys titanium ya fi kama da injin ƙarfe fiye da waɗanda ba na ƙarfe ba da gami. Yawancin sigogin tsari na alloys na titanium a cikin ƙirƙira, stamping ƙara da tambarin takarda suna kusa da waɗanda ke cikin sarrafa ƙarfe. Amma akwai wasu muhimman abubuwa waɗanda dole ne a kula da su lokacin da ake latsa kayan aikin Chin da Chin.

Ko da yake an yi imani da cewa lattice hexagonal da ke cikin titanium da titanium alloys ba su da ductile idan sun lalace, hanyoyin aikin jarida daban-daban da ake amfani da su don wasu karafa na tsarin su ma sun dace da alloys titanium. Matsakaicin ma'anar yawan amfanin ƙasa zuwa iyakar ƙarfi ɗaya ne daga cikin alamomin halayen ko ƙarfe zai iya jure nakasar filastik. Mafi girma wannan rabo, mafi muni da filastik na karfe. Don titanium mai tsabta na masana'antu a cikin yanayin sanyaya, rabon shine 0.72-0.87, idan aka kwatanta da 0.6-0.65 don ƙarfe na carbon da 0.4-0.5 don bakin karfe.

Aiwatar da tambarin ƙara, ƙirƙira kyauta da sauran ayyukan da suka danganci sarrafa babban ɓangaren giciye da manyan sarari a cikin yanayi mai zafi (sama da yanayin canjin = yS). Matsakaicin zafin jiki na ƙirƙira da dumama stamping yana tsakanin 850-1150 ° C. Alloys BT; M0, BT1-0, OT4 ~ 0 da OT4-1 suna da nakasar filastik mai gamsarwa a cikin yanayin sanyaya. Saboda haka, sassan da aka yi da waɗannan allunan galibi ana yin su ne da tsaka-tsaki masu ɓarna ba tare da dumama da tambari ba. Lokacin da gami da titanium ya yi sanyi nakasar filastik, ba tare da la'akari da sinadarai da kaddarorin injina ba, ƙarfin zai inganta sosai, kuma za a rage girman filastik daidai. A saboda wannan dalili, dole ne a yi maganin annealing tsakanin matakai.

Rashin lalacewa na saka tsagi a cikin machining na titanium alloys shine lalacewa na gida na baya da gaba a cikin zurfin yanke, wanda sau da yawa yakan haifar da taurin Layer da aka bari ta hanyar aiki na baya. Halin sinadarai da yaduwar kayan aiki da kayan aikin aiki a yanayin aiki sama da 800 ° C suma suna daya daga cikin dalilan samuwar tsagi. Domin a lokacin da machining tsari, da titanium kwayoyin na workpiece tara a gaban ruwa da aka "welded" zuwa ruwa gefen karkashin high matsa lamba da kuma high zafin jiki, forming wani gina-up gefen. Lokacin da gefen da aka gina shi ya cire gefen yanke, an cire murfin carbide na abin da aka saka.

Saboda juriya na zafi na titanium, sanyaya yana da mahimmanci a cikin aikin injin. Manufar sanyaya shine don kiyaye shingen yankewa da kayan aiki daga zafi mai zafi. Yi amfani da na'urar sanyaya ƙarewa don mafi kyawun ficewar guntu yayin yin aikin niƙa kafada da kuma jujjuyawar fuska, aljihu ko cikakken tsagi. Lokacin yankan ƙarfe na titanium, kwakwalwan kwamfuta suna da sauƙi don mannewa ga yankan, yana haifar da zagaye na gaba na abin yankan niƙa don sake yanke kwakwalwan kwamfuta, sau da yawa yana haifar da layin gefe zuwa guntu.

Kowane rami mai sakawa yana da nasa ramin sanyaya / allura don magance wannan batu da haɓaka aikin ci gaba mai dorewa. Wani m bayani ne threaded sanyaya ramukan. Masu yankan niƙa mai tsayi suna da abubuwan sakawa da yawa. Aiwatar da sanyaya zuwa kowane rami yana buƙatar babban ƙarfin famfo da matsa lamba. A gefe guda, yana iya toshe ramukan da ba a buƙata ba kamar yadda ake buƙata, ta haka yana haɓaka kwarara zuwa ramukan da ake buƙata.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes