Maƙerin Mashin ɗin ku na Mahimmanci

KYAKKYAWAR MASHI

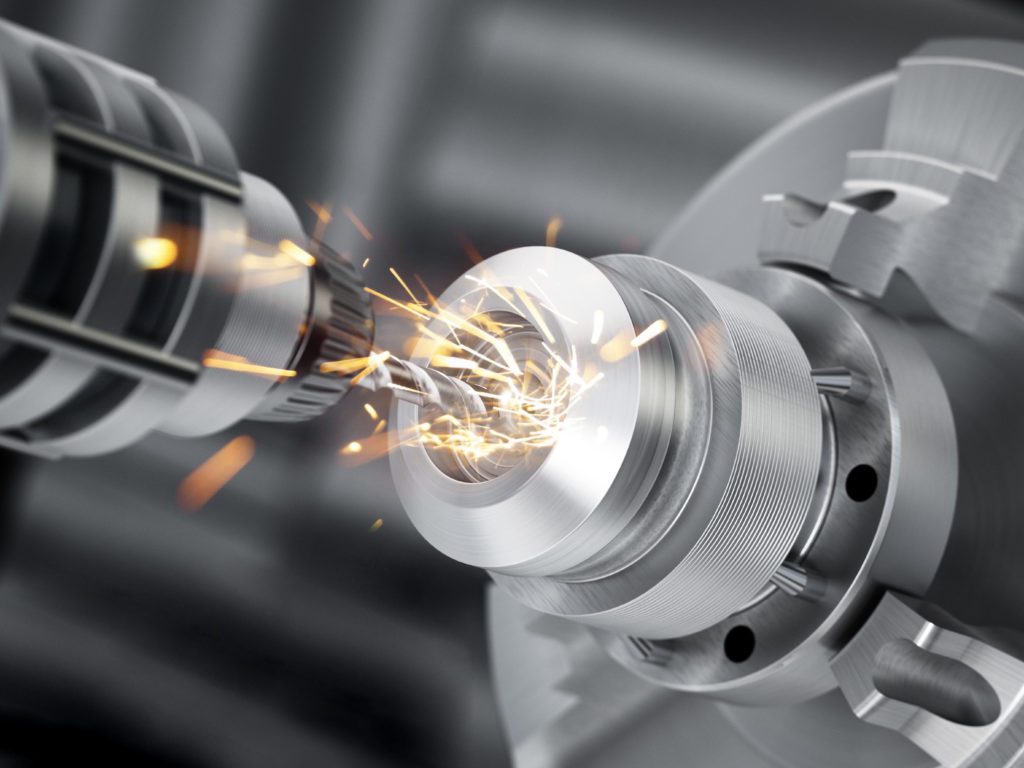

Mashin daidaitaccen tsari tsari ne wanda ake canza siffa ko aikin aikin ta hanyar injin sarrafa kayan aiki.Dangane da yanayin yanayin zafin aikin aikin da za a sarrafa, an raba shi zuwa sarrafa sanyi da sarrafa zafi.Yawanci, aiki a dakin da zafin jiki, kuma baya haifar da sinadarai ko canje-canje na lokaci na workpiece, ana kiran shi aikin sanyi.Gabaɗaya, sarrafawa a sama ko ƙasa da zafin jiki na al'ada zai haifar da canjin sinadarai ko lokaci na aikin aikin, wanda ake kira sarrafa thermal.Ana iya raba sarrafa sanyi zuwa yanke sarrafawa da sarrafa matsa lamba bisa ga bambancin hanyoyin sarrafawa.Sarrafa thermal yawanci ya haɗa da maganin zafi, ƙirƙira, simintin ƙarfe da walda.

Sarrafa kayan aikin mota shine naúrar da ta ƙunshi gabaɗayan sarrafa sassan mota da kuma samfuran da ke sarrafa kayan keɓaɓɓu.A matsayin kafuwar masana'antar kera motoci, sassan motoci sune abubuwan da suka dace don tallafawa ci gaba mai dorewa da lafiya na masana'antar kera motoci.Musamman ma, ci gaba mai zaman kansa na yanzu da ƙirƙira a cikin masana'antar kera motoci da ake aiwatarwa da ƙarfi kuma cikin sauri yana buƙatar tsarin sassa masu ƙarfi don tallafawa.Samfuran masu zaman kansu na abin hawa da ƙirƙira na fasaha suna buƙatar ɓangarori da abubuwan haɗin gwiwa a matsayin tushe, kuma sabbin abubuwa masu zaman kansu da abubuwan haɗin gwiwa suna da ƙarfin tuƙi don haɓaka masana'antar abin hawa.Suna yin tasiri da hulɗa da juna.Babu wata alama mai zaman kanta ta cikakkun motoci, da tsarin sassa masu ƙarfi.R & D da ƙwarewar haɓakawa na kamfanin suna da wuya a fashe, kuma ba tare da goyon bayan tsarin tsarin mai ƙarfi ba, zai zama da wahala ga samfuran masu zaman kansu su zama masu girma da ƙarfi.

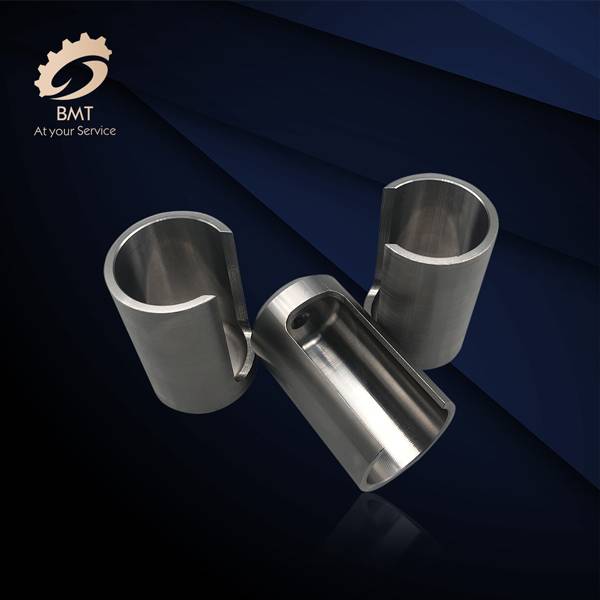

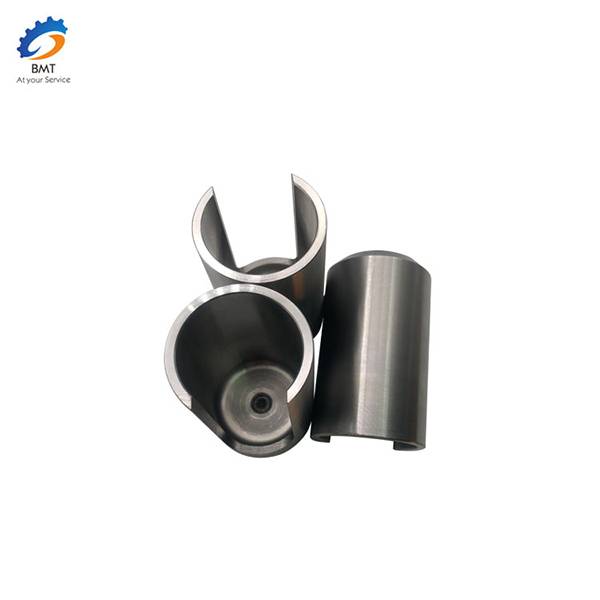

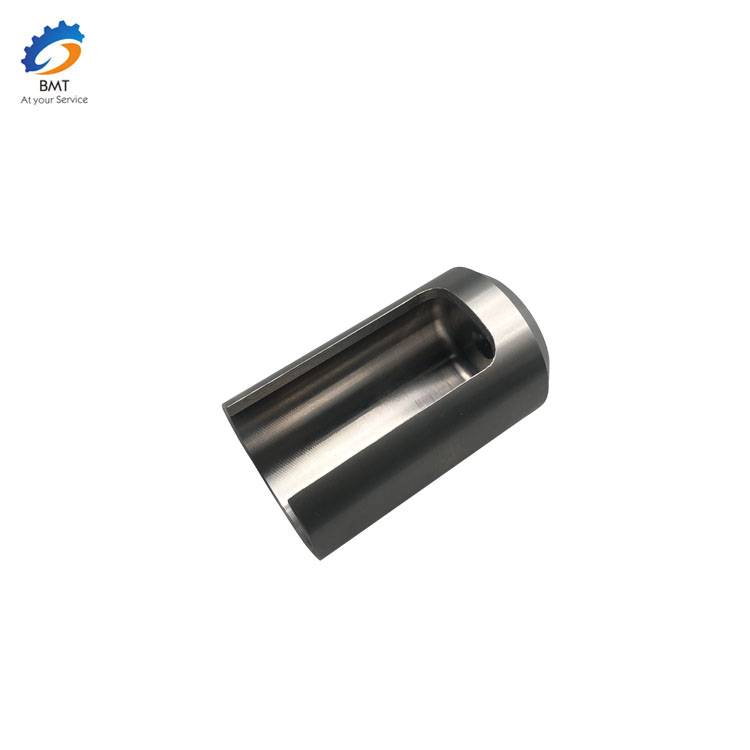

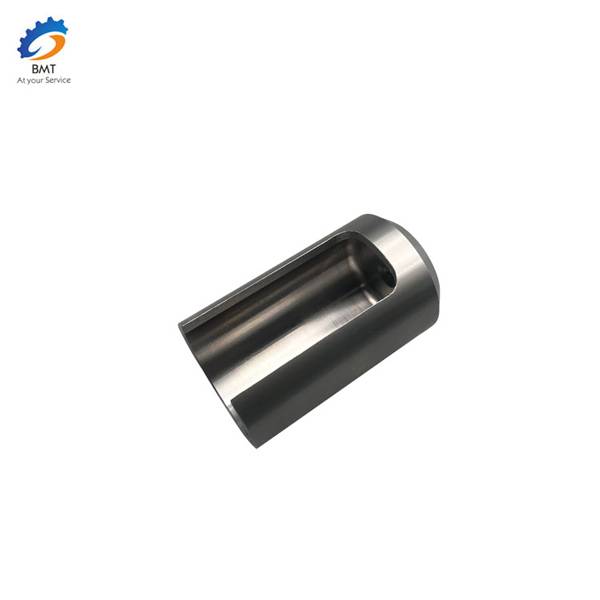

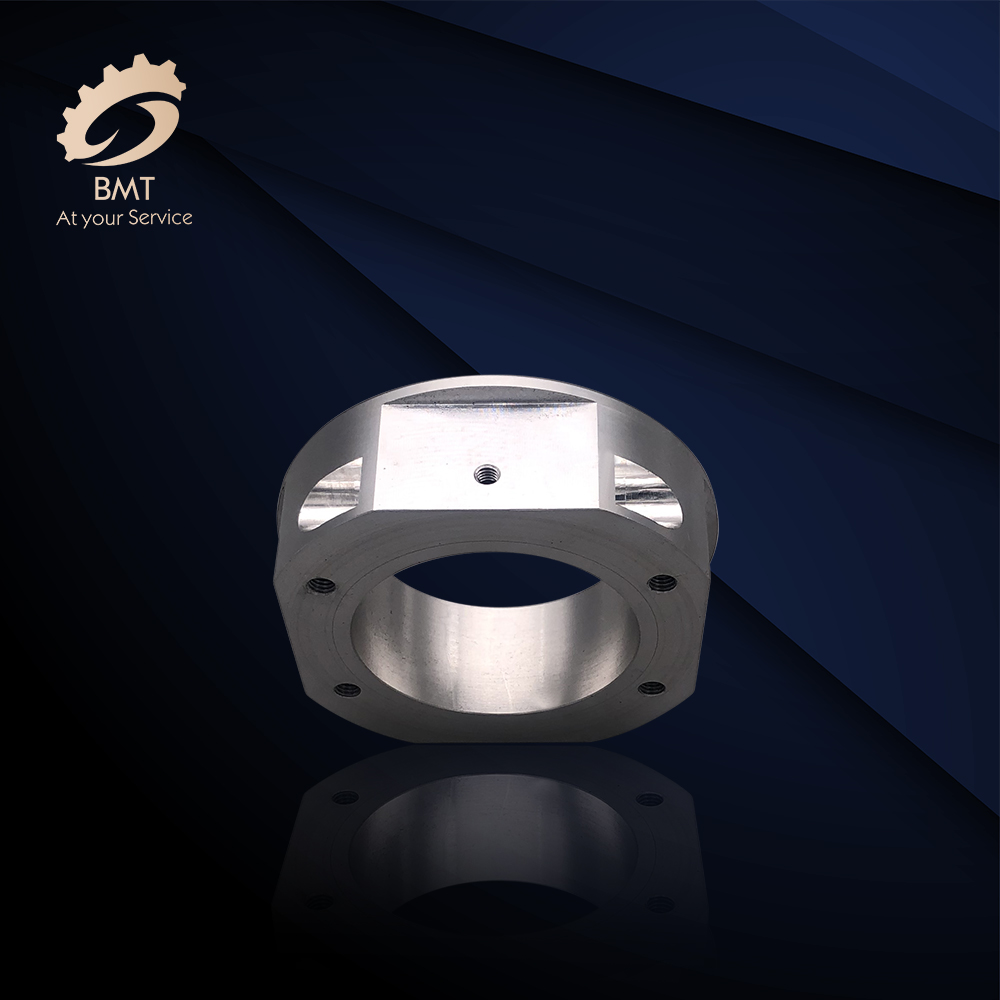

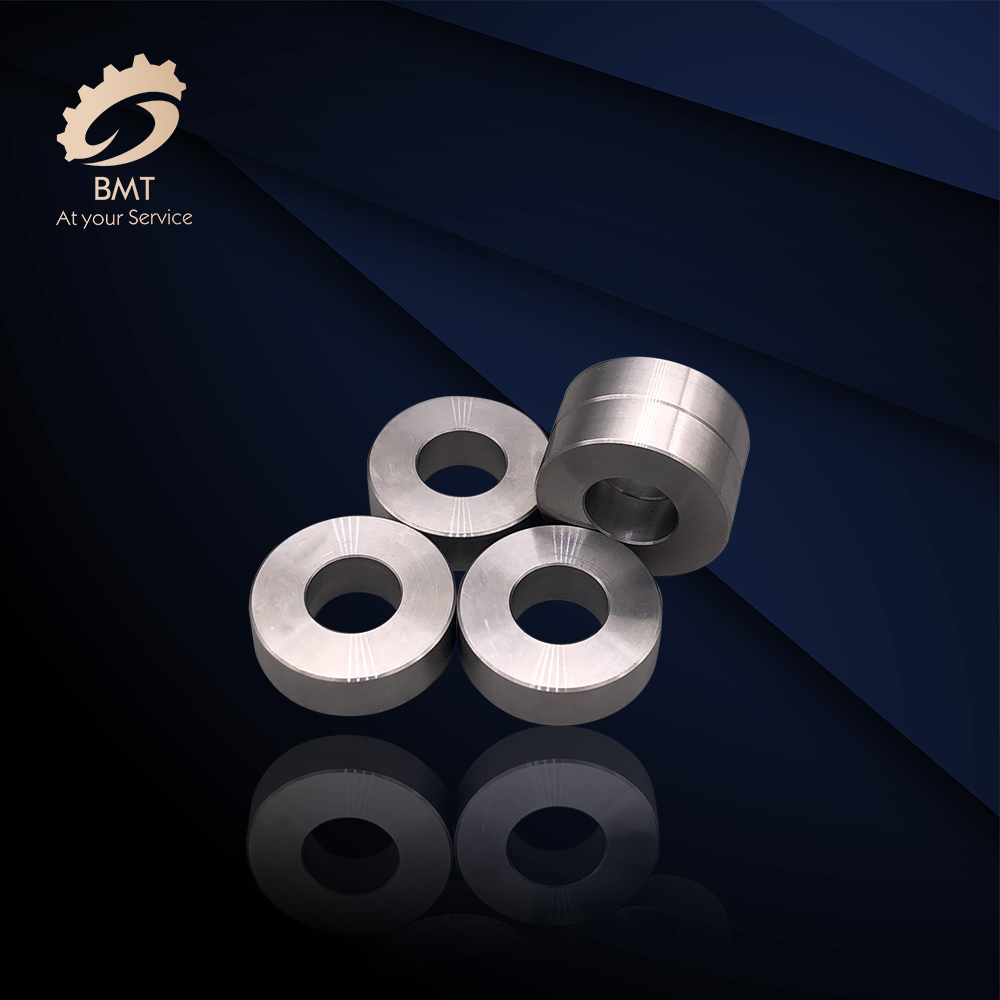

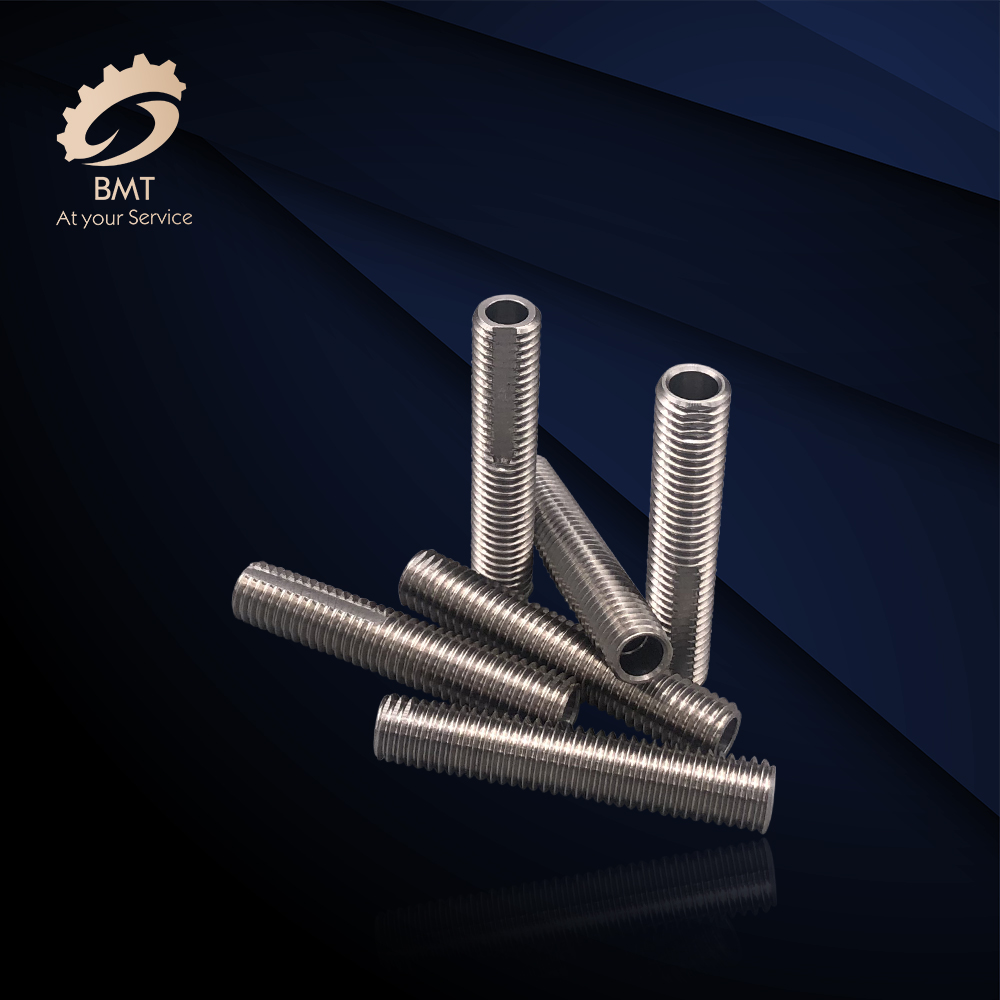

Sassan suna nufin sassa ɗaya waɗanda ba za a iya raba su cikin injina ba.Su ne ainihin abubuwan da ke cikin injin da kuma naúrar asali a cikin tsarin kera na'ura.Tsarin masana'antu gabaɗaya baya buƙatar tsarin taro.Kamar hannun riga, bushes, goro, crankshafts, ruwan wukake, gears, cams, haɗa jikin sanda, haɗa kawunan sanda, da dai sauransu. Don mashin ɗinmu na gaskiya, sarrafa yana da tsauri sosai, kuma hanyoyin sarrafawa sun haɗa da yanke ciki da waje.Akwai takamaiman buƙatu don girman da daidaito, kamar 1mm plus ko debe micrometers, da sauransu. Idan girman ya yi girma sosai, za a ɓata.A wannan lokacin, yana daidai da sake sarrafawa, cin lokaci da wahala, kuma wani lokacin ma duk kayan da aka sarrafa ana goge su.Wannan ya haifar da karuwar farashi, kuma a lokaci guda, sassan ba su da amfani.

Wasu kayan aiki na yau da kullun ba za su iya gama sarrafa ƙirar ƙira ba, kamar wasu cavities tare da ƙananan kusurwar R;Ana sarrafa na'urorin lantarki ta hanyar bugun jini.Yawanci ana yin waɗannan da jan ƙarfe ko graphite.Haɓakawa da sauri na fasahar kera ƙira ya zama muhimmin ɓangare na fasahar kere kere na zamani.Fasahar masana'anta na zamani tana haɓakawa a cikin hanyar haɓaka fitar da bayanai, haɓaka sassauƙan masana'anta, masana'anta agile da haɗin tsarin.An bayyana shi musamman a cikin fasahar CAD/CAM na mold, fasahar fasaha ta Laser mai saurin ƙira ta mold, daidaitaccen ƙirar ƙirar ƙirar ƙirar, da fasahar sarrafa kayan ƙira.Tsarin ƙira yana amfani da hanyar ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun iyaka don aiwatar da kwarara, sanyaya da tsarin canja wurin zafi.Fasahar siminti mai ƙarfi, fasahar CIMS mold, fasahar kere kere kamar fasahar DNM mold da fasahar sarrafa lambobi an haɓaka.