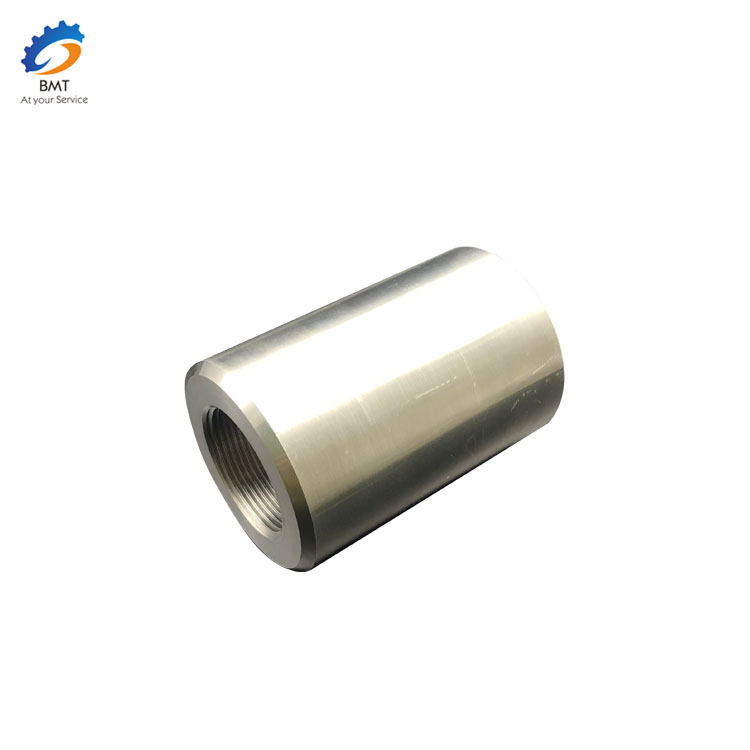

OEM Machining Service daga BMT

Matakan KafaMachiningTsarin Tsari

1) Ƙididdige shirin samarwa na shekara-shekara kuma ƙayyade nau'in samarwa.

2) Yi nazarin zane-zane da zane-zane na samfurin, da aiwatar da nazarin sassa.

3) Zaɓi wuraren da ba komai.

4) Ƙirƙirar hanyar tsari.

5) Ƙayyade izinin machining na kowane tsari, ƙididdige girman tsari da haƙuri.

6) Ƙayyade kayan aiki da kayan aiki, kayan aiki, kayan aikin aunawa da kayan aiki masu taimako da ake amfani da su a kowane tsari.

7) Ƙayyade yankan sashi da adadin lokaci.

8) Ƙayyade buƙatun fasaha da hanyoyin dubawa na kowane babban tsari.

9) Cika takardun tsari.

A cikin aiwatar da hanyoyin fasaha, sau da yawa ya zama dole don daidaita abubuwan da aka riga aka ƙaddara a gaba, don haɓaka fa'idodin tattalin arziki.A cikin aiwatar da hanyoyin aiwatarwa, ana iya samun yanayin da ba a zata ba, kamar canjin yanayi na samarwa, ƙaddamar da sabbin fasahohi, sabbin fasahohi, aikace-aikacen sabbin kayan aiki, kayan aikin ci gaba, da sauransu, duk suna buƙatar bita kan lokaci kuma inganta hanyoyin aiwatarwa.

Kuskuren inji yana nufin matakin karkacewa tsakanin ainihin sigogin lissafi (girman geometric, siffar geometric da matsayi na juna) da madaidaicin ma'auni na geometric bayan injin.Bayan mashin ɗin, matakin daidaituwa tsakanin ainihin ma'auni na geometric da ingantattun sigogin lissafi shine daidaiton injina.Karamin kuskuren mashin ɗin, mafi girman matakin daidaito, mafi girman daidaiton mashin ɗin.Machining machining kuskuren machining tsari ne guda biyu na matsala iri ɗaya.Saboda haka, girman kuskuren sarrafawa yana nuna daidaiton aiki.

1. Machine Tool Manufacturing kuskure inji kayan aikin masana'antu kuskure yafi hada da spindle juyawa kuskure, jagora dogo kuskure da kuma watsa sarkar kuskure.Kuskuren juyawa na spindle yana nufin ainihin madaidaicin jujjuyawar sandal na kowane lokaci dangane da matsakaicin jujjuyawar canjin sa, zai shafi daidaitaccen aikin aikin da ake sarrafa shi kai tsaye.Babban dalilan da ke haifar da kuskuren juyawa na spindle shine kuskuren coaxial na spindle, kuskuren ɗaukar kanta, kuskuren coaxial tsakanin bearings, spindle winding, da dai sauransu. Hanyar jagora ita ce datum don ƙayyade matsayi na dangi na kowane. Sashin kayan aikin injin akan kayan aikin injin, shima shine datum na motsin kayan aikin injin.Kuskuren masana'antu, rashin daidaituwa da ingancin shigarwa na dogo jagora sune mahimman abubuwan da ke haifar da kuskuren layin jagora.Kuskuren sarkar watsawa yana nufin kuskuren motsi na dangi tsakanin abubuwan watsawa a ƙarshen sarkar watsawa.Ana haifar da kurakuran masana'anta da haɗakarwa na kowane haɗin haɗin gwiwa a cikin sarkar watsawa, da lalacewa da tsagewa a cikin tsarin amfani.

2. Kuskuren geometric na kayan aiki duk wani kayan aiki a cikin tsarin yankan ba makawa ne don samar da lalacewa, don haka ya sa girman da siffar kayan aiki ya canza.Tasirin kuskuren lissafi na kayan aiki akan kuskuren machining ya bambanta da nau'ikan kayan aiki daban-daban: lokacin amfani da ƙayyadaddun ƙayyadaddun kayan aikin yankan, kuskuren masana'anta na kayan aikin zai shafi daidaitaccen mashin ɗin aikin;Koyaya, don kayan aiki na gaba ɗaya (kamar kayan aikin juyawa), kuskuren masana'anta ba shi da tasiri kai tsaye akan kuskuren injin.