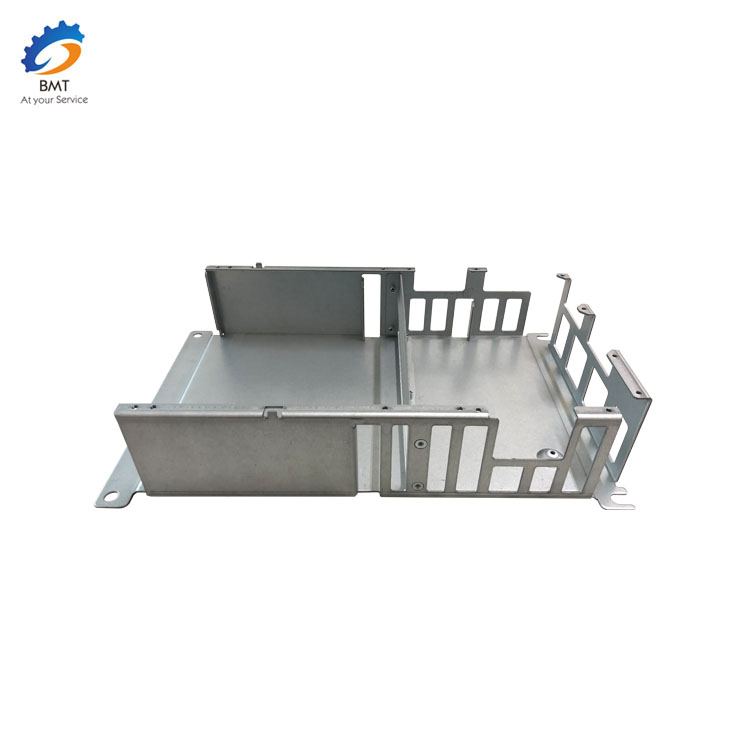

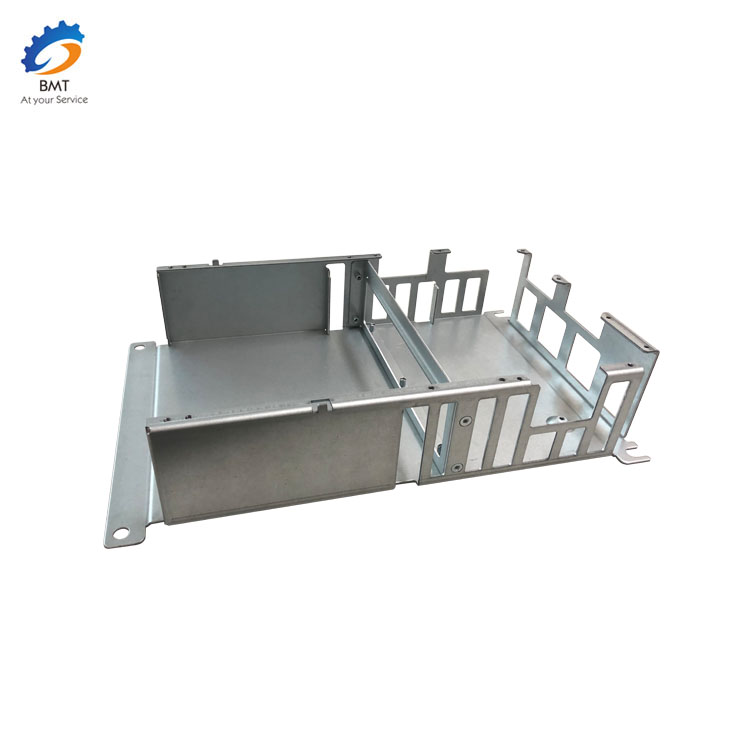

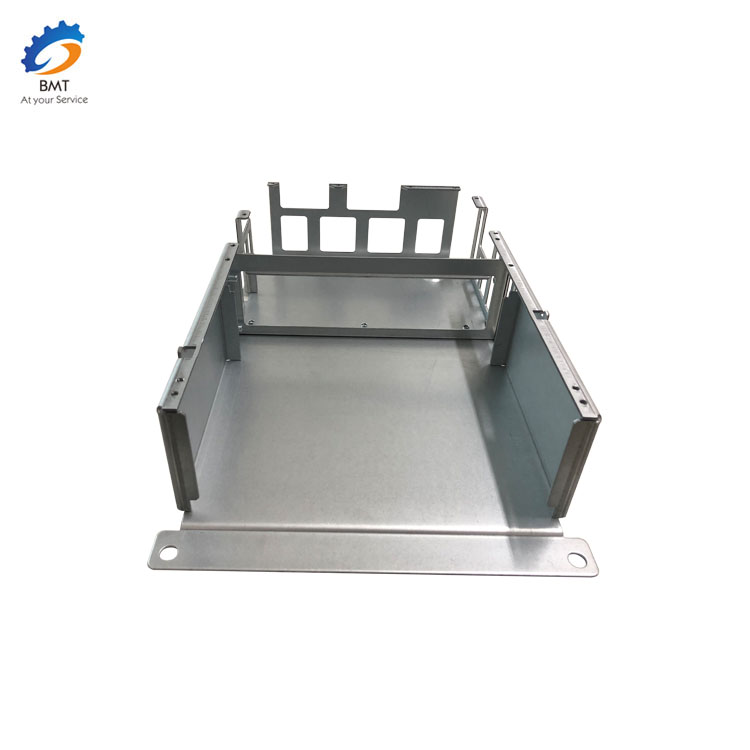

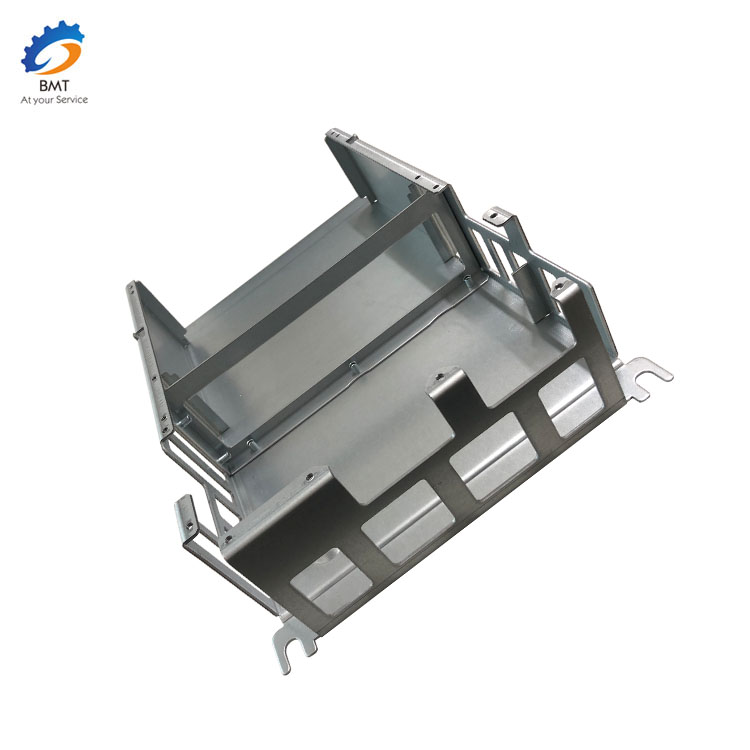

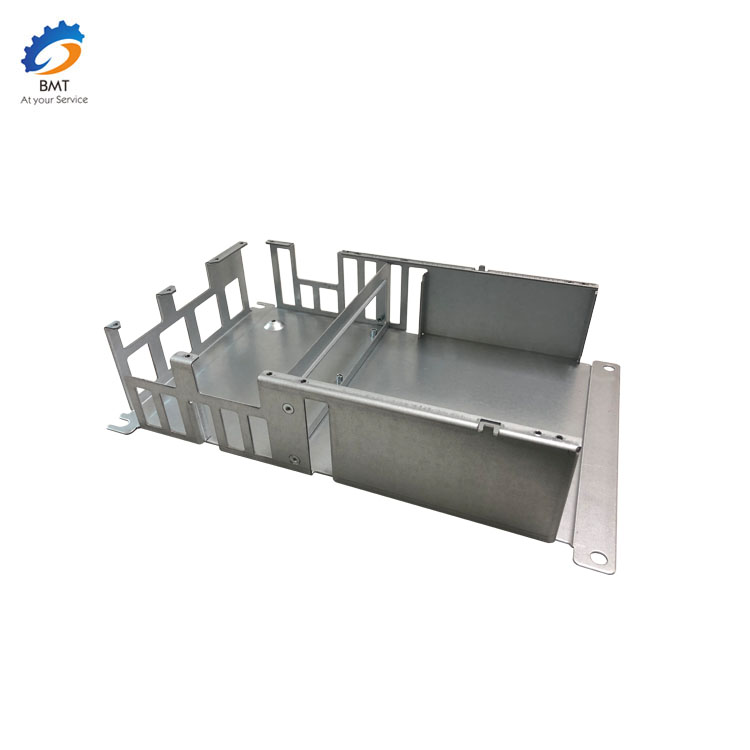

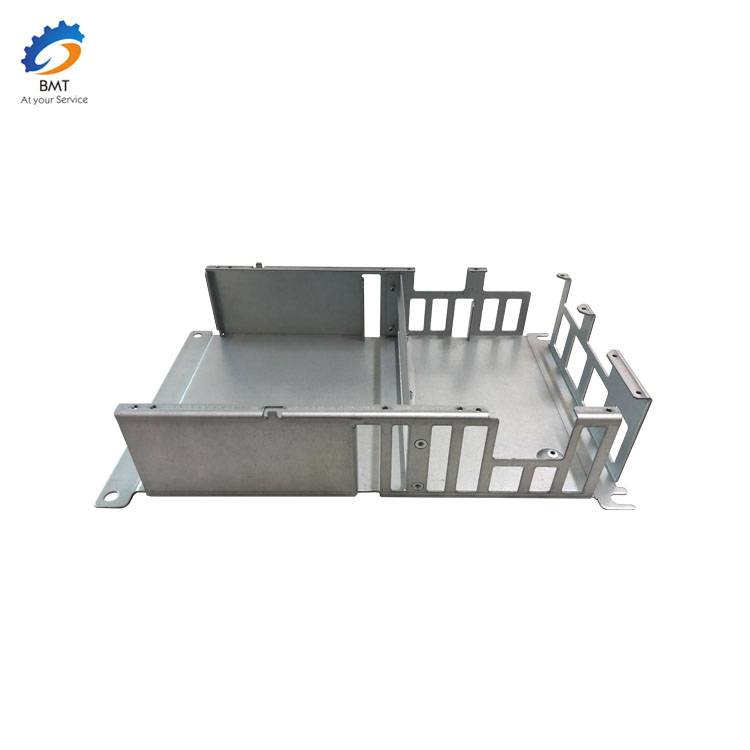

Tsarin Ƙarfe na Musamman na Ƙarfe

Ƙarfe na Ƙarfe na Custom yana da ɗan rikitarwa saboda ana iya gina shi zuwa kowane nau'i na siffofi, amma duk ci gaban masana'antu za a iya yanke shi cikin matakai uku kamar yadda ke ƙasa.

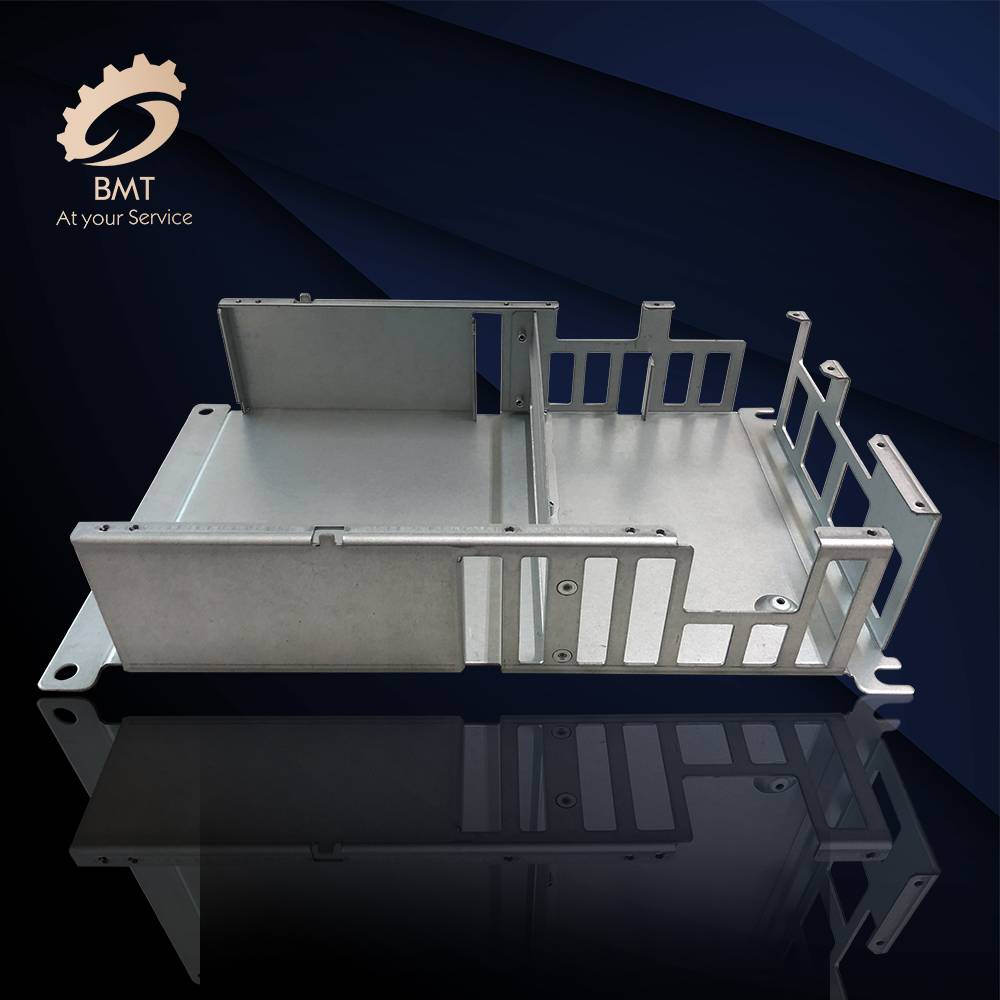

Na farko shine yanke ci gaba wanda kuma ake kira ci gaban cire kayan abu. A cikin wannan ci gaban, akwai hanyoyi daban-daban da suka haɗa da yankan Laser, yankan jet na ruwa, yankan plasma, da yankan naushi. Daga cikin su duka, Laser yankan ya ƙunshi amfani da Laser don cimma daidai yanke a cikin takardar karfe. Shi ne mafi daidai da makamashi-m fiye da wasu sauran yankan matakai ga babban size da kuma tunanin karfe takardar kayan, wanda kuma shi ne ya fi kowa hanya a cikin factory.

Yanke Punch, a gefe guda, wata hanya ce ta gama gari kuma ta fi dacewa da za a yi amfani da ita cikin ƙananan aikace-aikace.

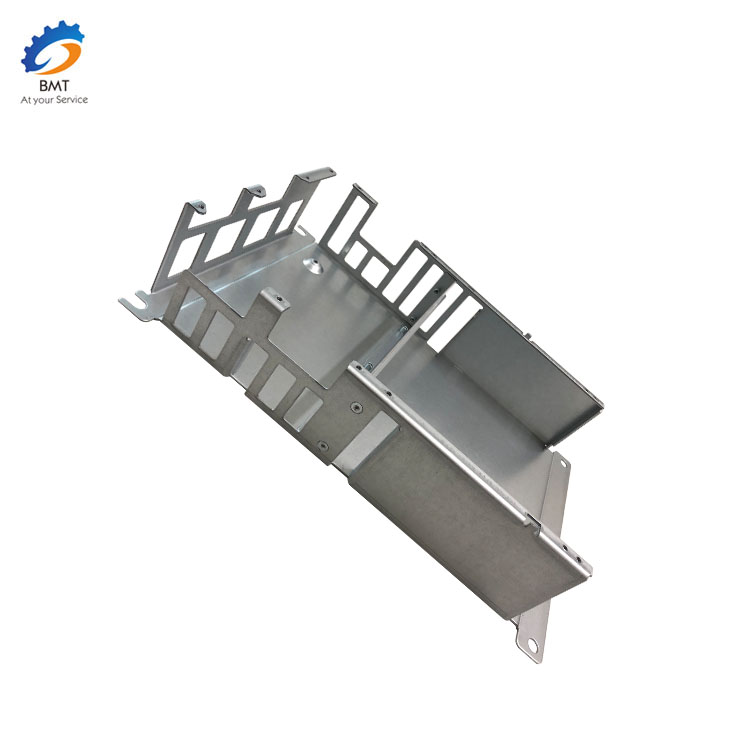

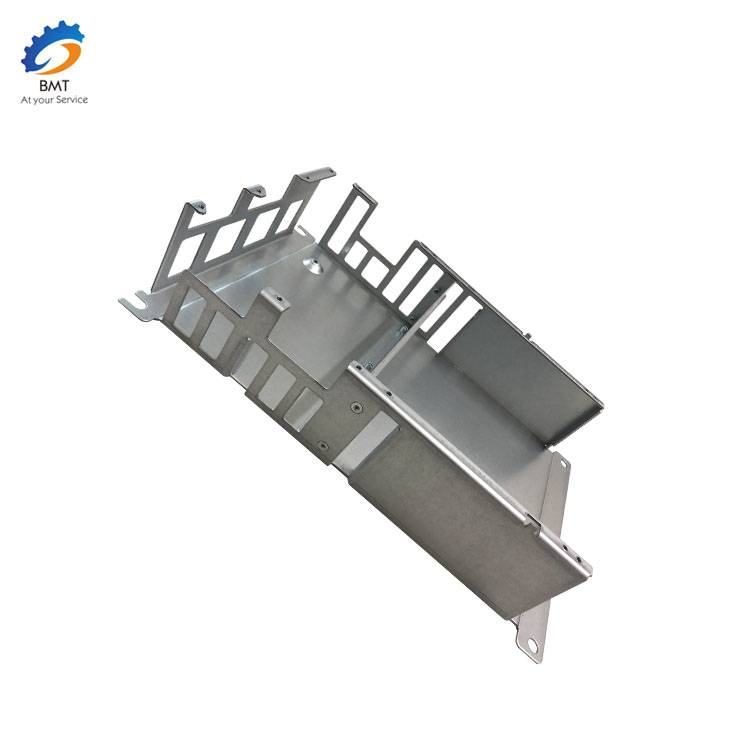

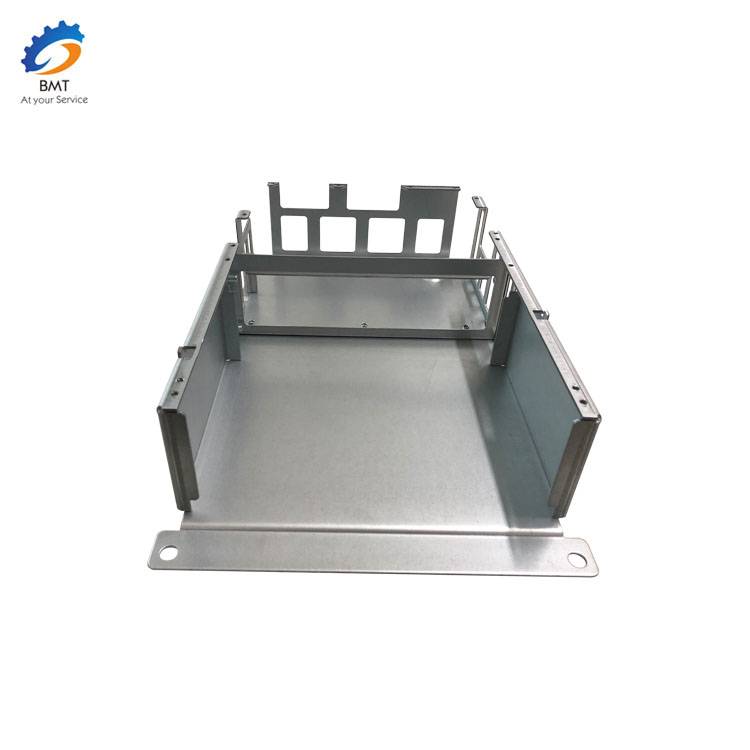

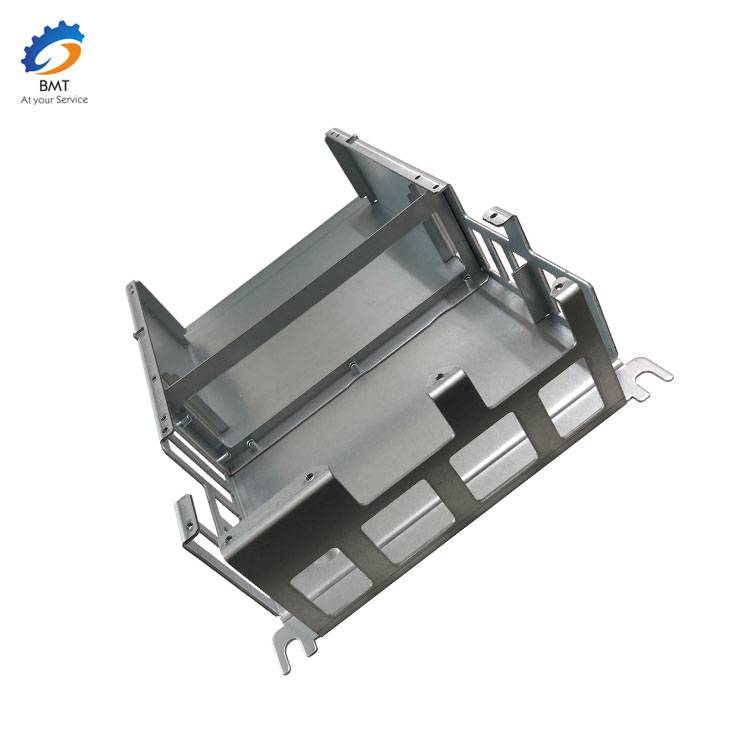

Bayan yankan, muna da kafa wanda kuma ake kira nakasar kayan abu. Akwai dabaru da dama na ƙirƙira waɗanda suka haɗa da mirgina, kadi, lankwasa, tambari, da walda.

A ƙarshe, yana gamawa. Wannan yana nufin ɓangarorin samfur ɗin da ake goge su tare da abrasive don kawar da tabo da gefuna da kuma samun siffa mai santsi. Bayan wannan tsari, yawanci kuma ya haɗa da ci gaban gamawa kamar fenti da anodizing.

Menene Nau'ikan Kera?

Akwai nau'ikan hanyoyin ƙirƙira ƙarfe daban-daban da yawa. Daga cikin su, mafi yawan sun haɗa da Yanke, naɗewa, ƙirƙira, naushi, tambari, walda, da goge goge. Don ƙirƙira sashe ɗaya, ƙila mu buƙaci matakai ɗaya ko da yawa a sama waɗanda suka dogara da ƙirar sashe. Misali, muna iya buƙatar tsarin yanke kawai don ɓangaren takarda ɗaya. Amma ƙila mu yi amfani da duk matakan da ke sama don babban samfurin majalisar.

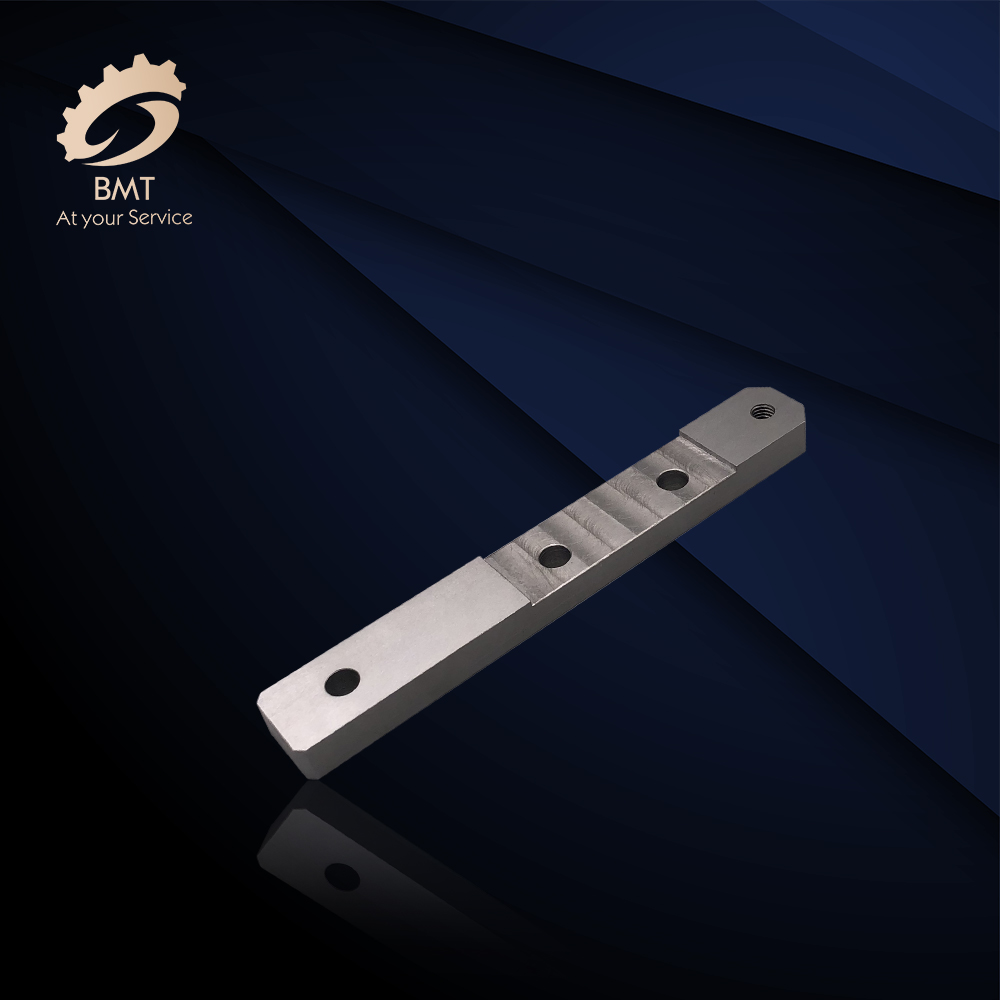

Menene Girman Kaurin Sheet Na Ƙarfe?

Sai dai idan ba mu haɗa guda biyu zuwa yanki ɗaya ba, kaurin kayan ƙarfe ya kamata koyaushe ya kasance daidai. Baya ga wannan, akwai nau'ikan karafa iri-iri, kuma kaurin takardar na iya zuwa daga inci 0.02 zuwa inci 0.25.

Nawa ne Farashin Ƙarfe na Ƙarfe na Musamman?

Ya dogara. Gabaɗaya farashi na ɓangaren ƙarfe na takarda na al'ada ya dogara da abubuwa da yawa waɗanda suka haɗa da girman ɓangaren ƙarfe, abu, rikitarwa, da adadin siye.

A cikin kalma, ƙarancin farashin kayan abu da ƙarancin lokacin ƙirƙira dangane da MOQ iri ɗaya, farashin yana da ƙasa. Domin warware matsalolin masana'antu na juyowa, tuntube mu yanzu kuma mun ɗauki zafi daga gare ku. Muna da mahimmanci ga CNC Machining da Sheet Metal.

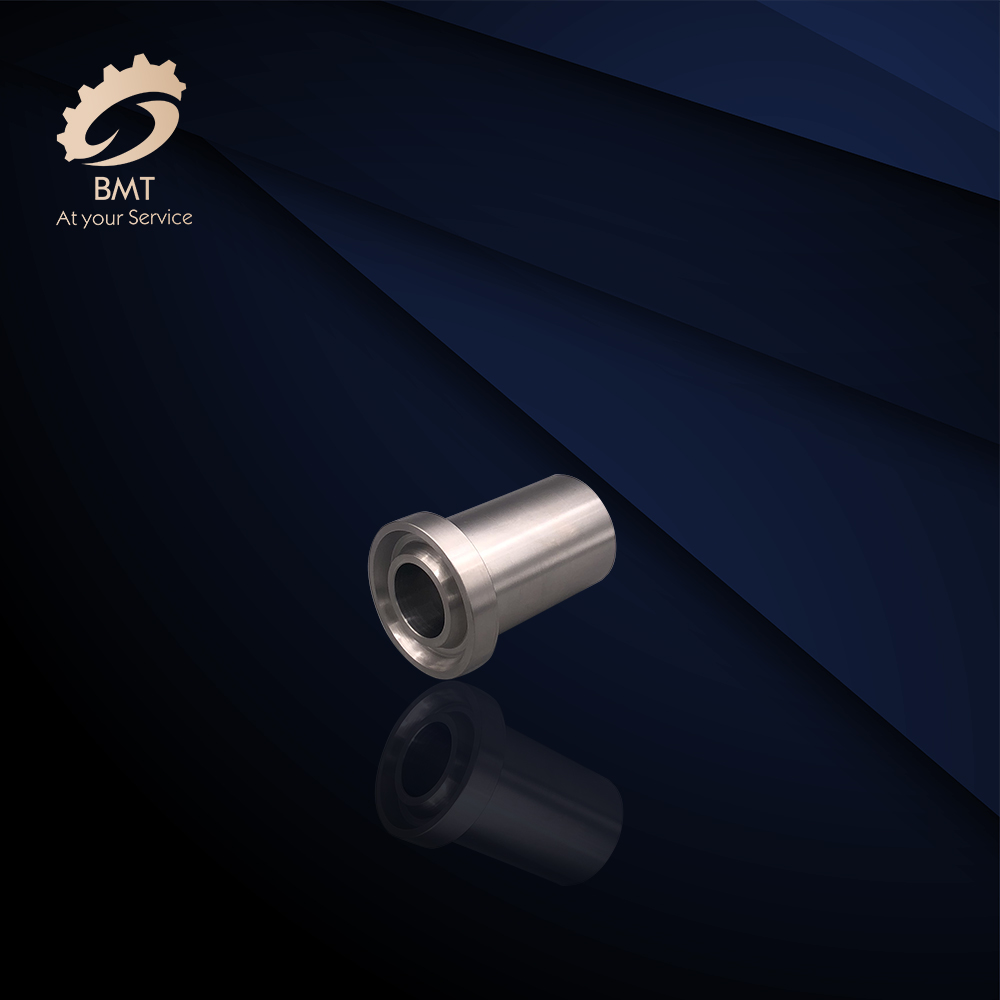

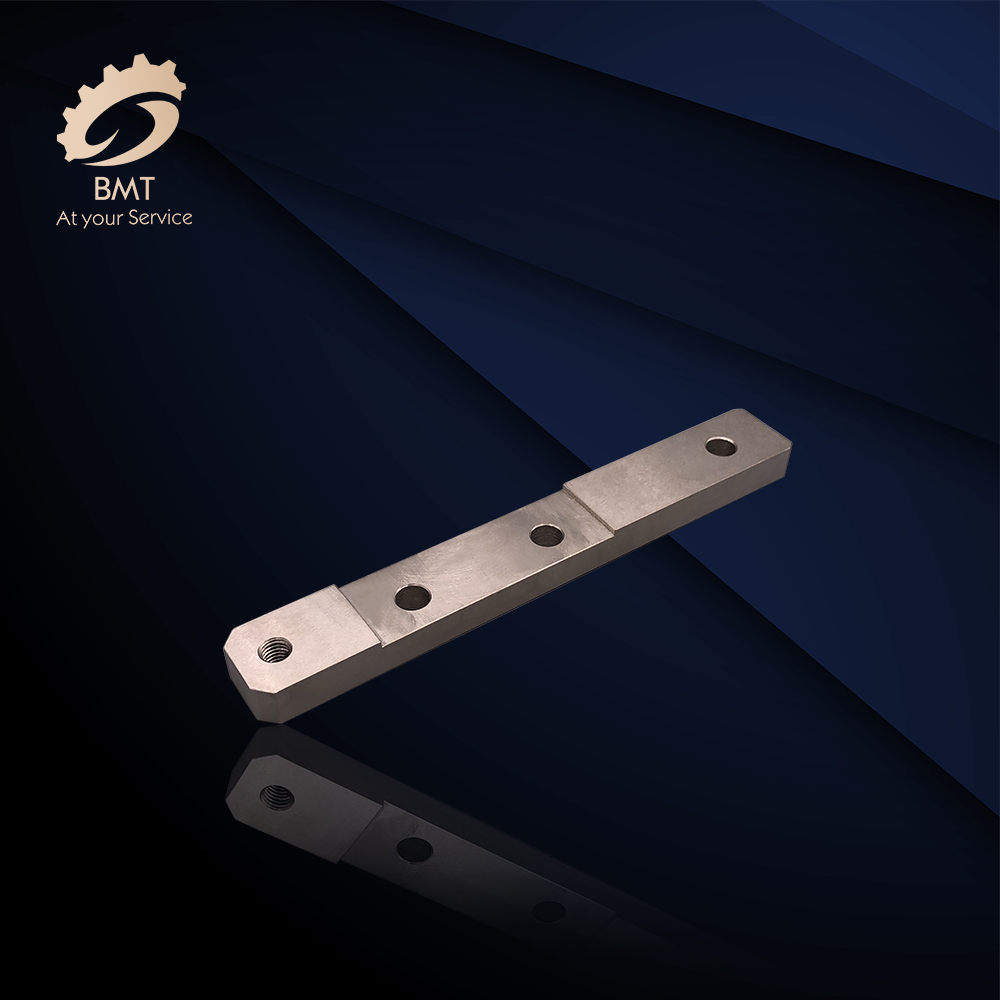

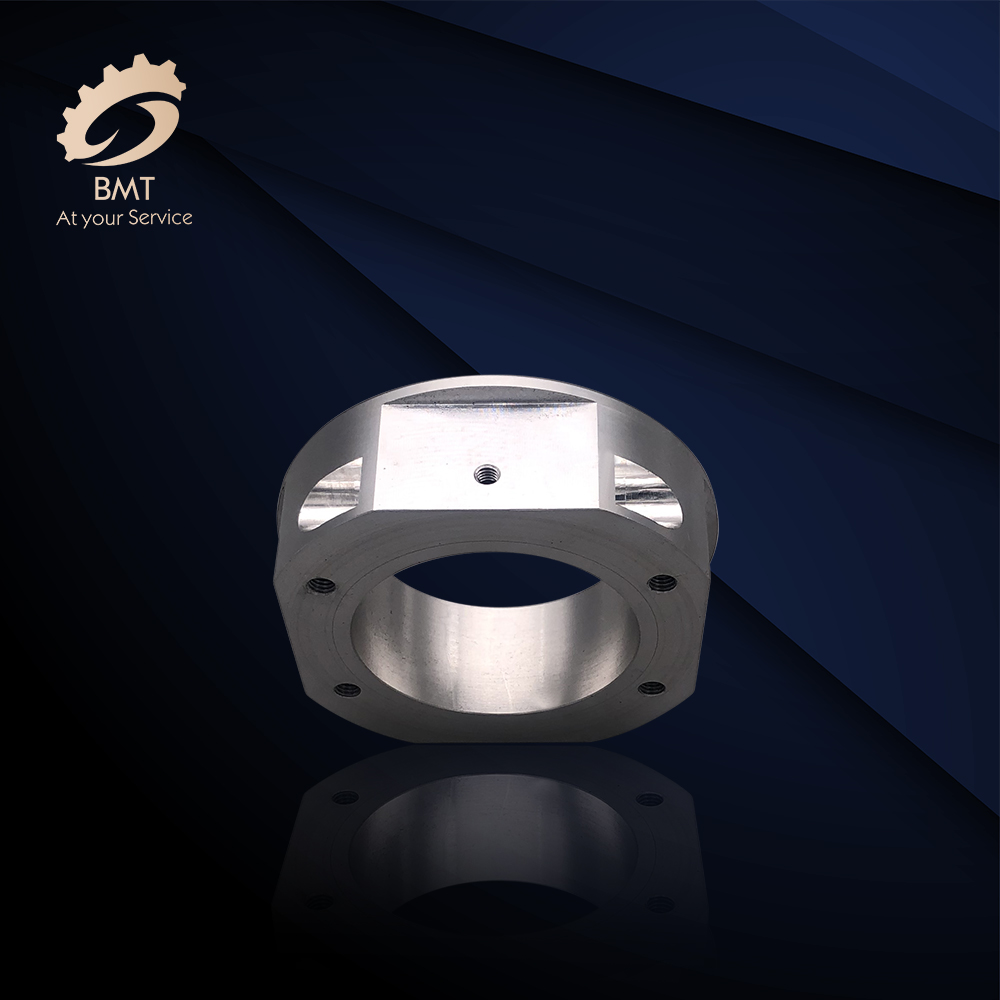

Ƙirƙirar ƙarfe na takarda ita ce hanyar da za ku iya juyar da zanen ƙarfe na ƙarfe ko wasu karafa zuwa samfura ko ba su tsari, ta hanyar yanke, lankwasa da haɗawa. Ana iya ƙirƙira ƙarfen takarda zuwa kusan kowace siffa, wanda galibi ana yin shi ta hanyar yanke da lanƙwasa ƙarfen.

Juriya Welding, Fadada Karfe, lankwasawa, Laser Yankan, shrinking, mikewa, naushi, stamping, da dai sauransu su ne mafi muhimmanci hanyoyin a sheet karfe tafiyar matakai. Kuna buƙatar tabbatar da cewa kamfanin da kuke aiki da shi yana da damar da ke sama kuma ya ba ku sabis mafi kyau ba tare da wata shakka ba, koda kuwa farashin su ya ɗan yi girma, amma kuna iya samun abin da kuke so tare da cikakken inganci da amsoshi masu gamsarwa.

Bayanin Samfura