Aikin Nika

Yin nika na gama aikin injin ne (an raba injinan zuwa injina mai ƙarfi, injin gamawa, maganin zafi da sauran hanyoyin sarrafawa), tare da ƙarancin sarrafawa da ingantaccen daidaito. Ana amfani da shi sosai a masana'antar kera injina. The zafi bi da quenched carbon kayan aiki karfe da carburized da quenched karfe sassa sau da yawa da babban adadin a kai a kai shirya fasa - nika fasa - a kan surface cewa shi ne m perpendicular zuwa nika shugabanci a lokacin nika. Ba wai kawai yana rinjayar bayyanar sassan ba, har ma yana rinjayar ingancin sassan kai tsaye.

Yana nufin yankan aiwatar da workpiece surface da high-gudun juyawa nika dabaran da sauran abrasive kayan aikin. Ana amfani da niƙa don aiwatar da saman cylindrical na ciki da na waje, saman conical da jirage na kayan aiki daban-daban, da kuma na musamman da hadaddun filaye kamar su guntuwar Ge Ban, zaren, gears da splines.

Saboda tsananin taurin hatsin da aka yi da kai da kai na kayan aikin abrasive, ana iya amfani da niƙa don sarrafa abubuwa daban-daban, waɗanda suka haɗa da ƙarfe mai ƙarfi, ƙarfe mai ƙarfi mai ƙarfi, gami mai ƙarfi, gilashi, yumbu, marmara da sauran ƙarfe mai ƙarfi da sauran ƙarfi. kayan da ba na ƙarfe ba. Gudun niƙa yana nufin saurin madaidaiciyar dabaran niƙa, wanda yawanci shine 30 ~ 35 m/s. Idan ya wuce 45 m/s, ana kiran shi niƙa mai sauri.

Ana amfani da niƙa yawanci don kammalawa da ƙarewa, kuma daidaito zai iya kaiwa IT8 ~ 5 ko ma mafi girma. Tsawon yanayin gabaɗaya yana ƙasa zuwa Ra1.25 ~ 0.16 μm, daidaitaccen niƙa zuwa Ra0.16 ~ 0.04 μm, ƙwanƙwasa daidaitaccen niƙa zuwa Ra0.04 ~ 0.01 μm, da madubi niƙa zuwa Ra0.01 μm. Ƙarfin ƙayyadaddun ƙarfin niƙa (ko takamaiman amfani da makamashi, wato, makamashin da ake cinyewa don yanke kayan aiki a kowace juzu'in naúrar) ya fi girma fiye da na yankan gabaɗaya, kuma ƙimar cirewar ƙarfe ya fi na gama-gari.

Saboda haka, kafin nika, da workpiece yawanci cire da sauran yankan hanyoyin don cire machining izni na manyan sassa na Jiang Ali, barin kawai 0.1 ~ 1mm ko žasa na nika izni. Tare da haɓaka haɓakar niƙa mai inganci, kamar niƙan abinci mai raɗaɗi da niƙa mai girma, sassa na iya zama ƙasa kai tsaye daga blanks. Hakanan ana iya amfani da shi don ƙera mashin ɗin ta hanyar niƙa, kamar cire mai gudu da hawan simintin gyare-gyare, walƙiya na ƙirƙira da fatar ƙarfe na ƙarfe.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

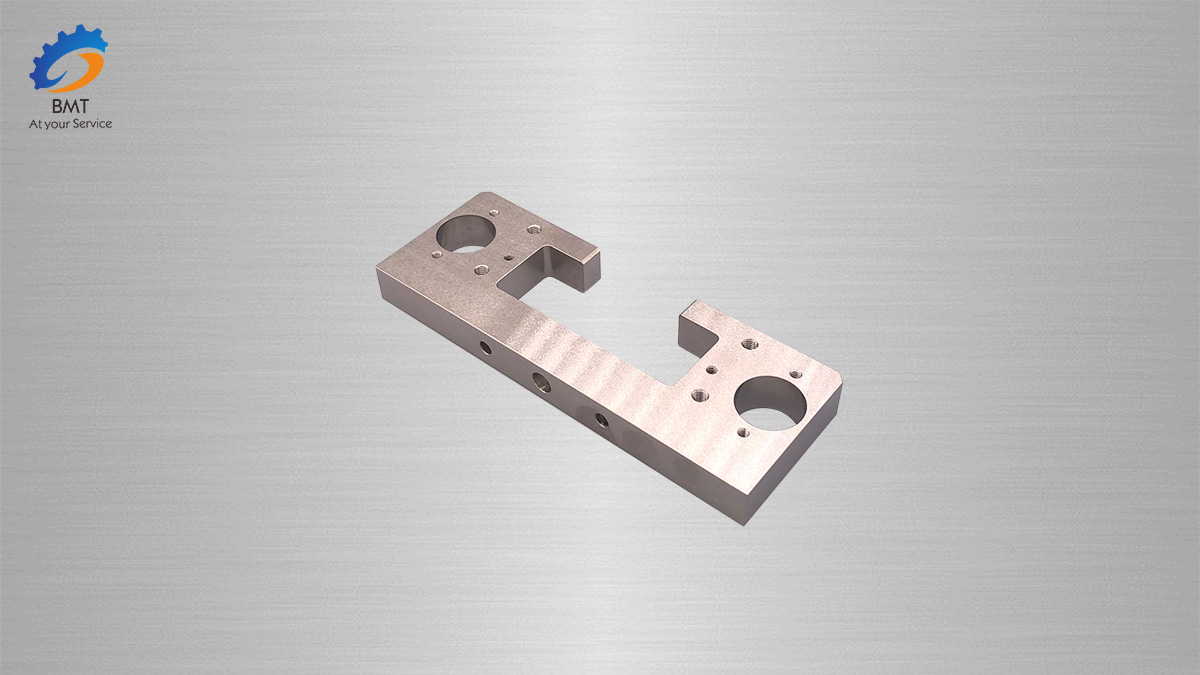

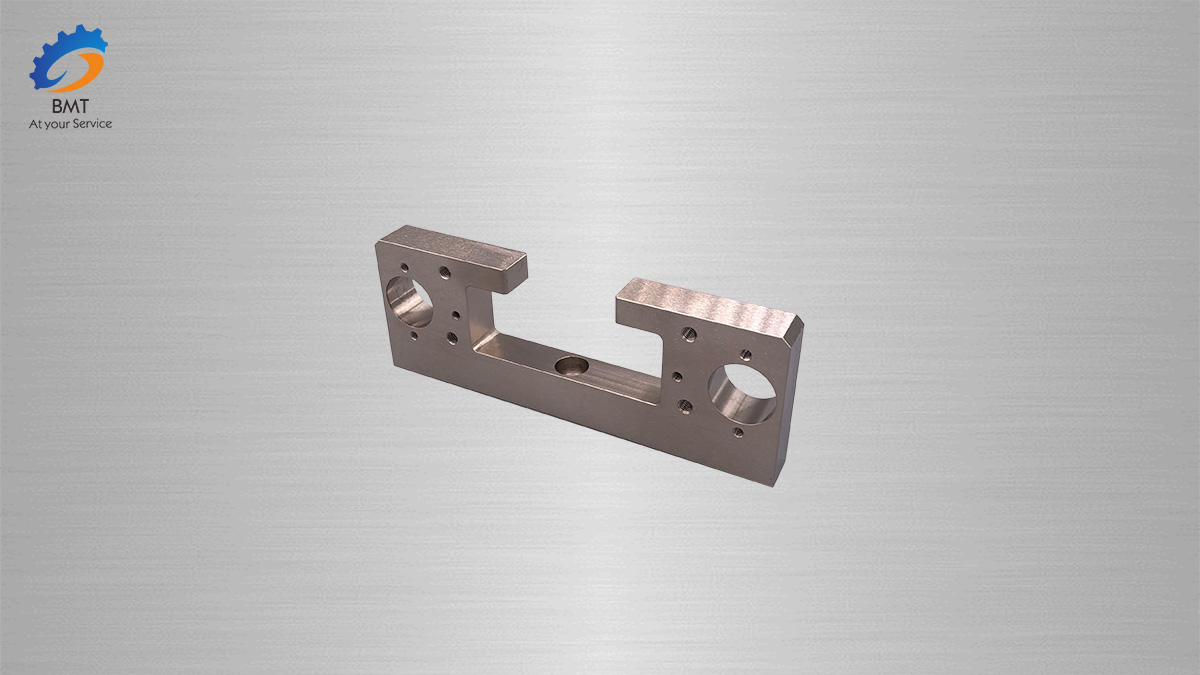

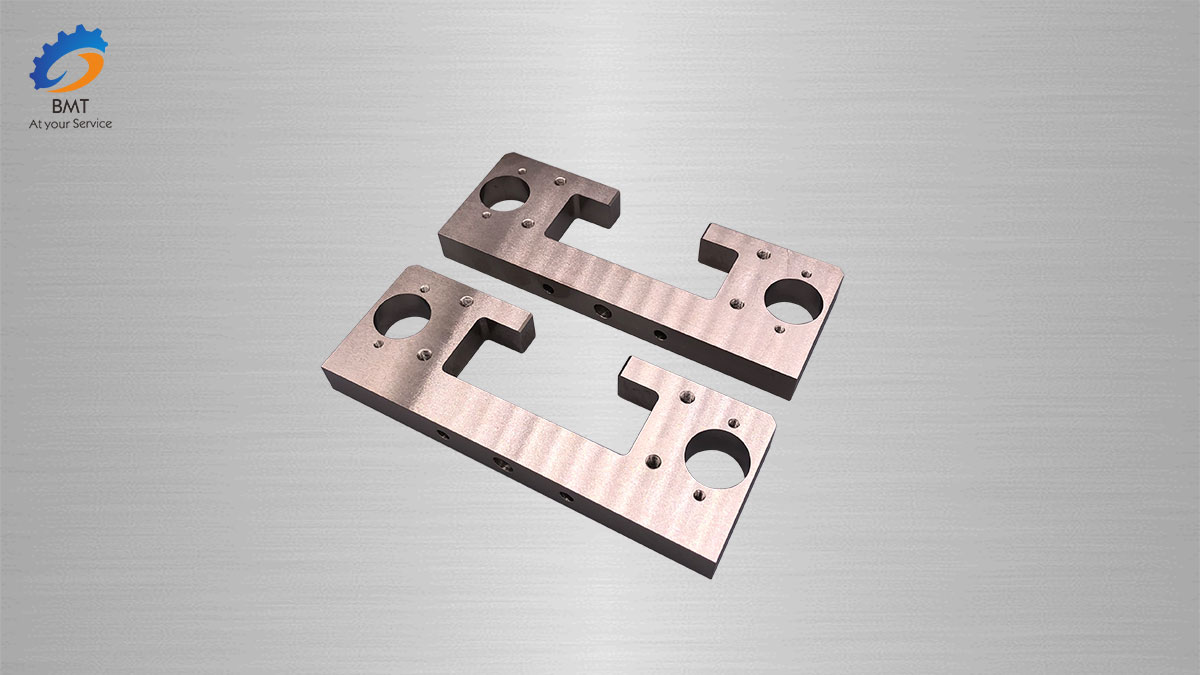

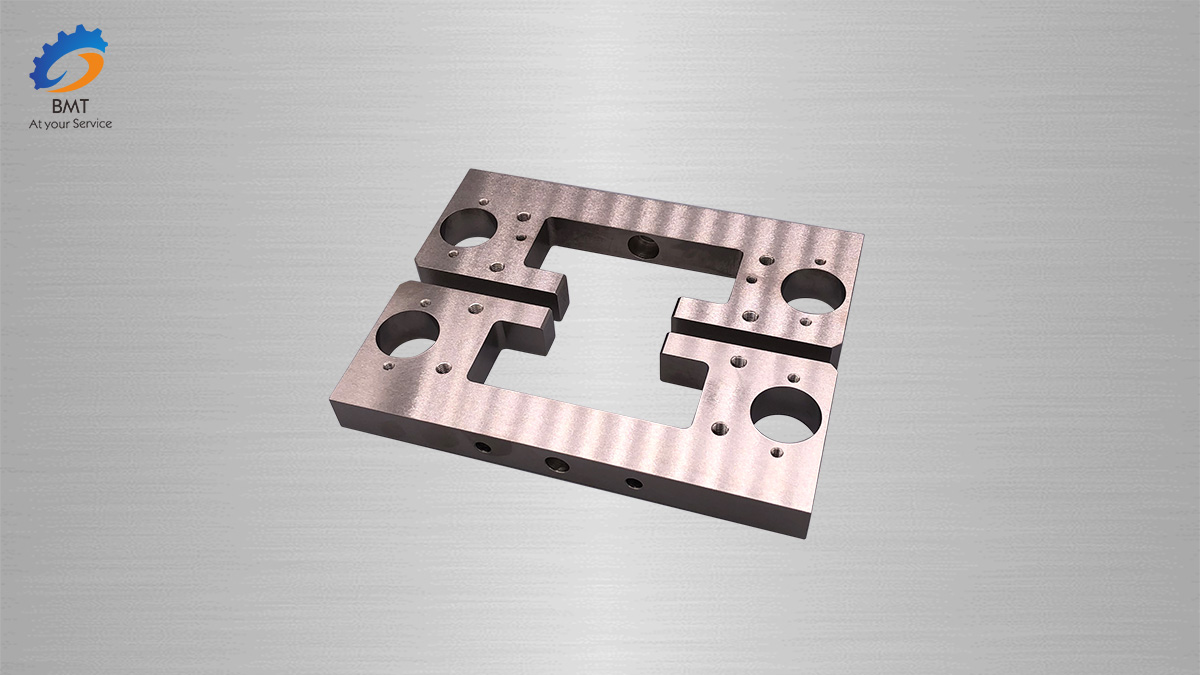

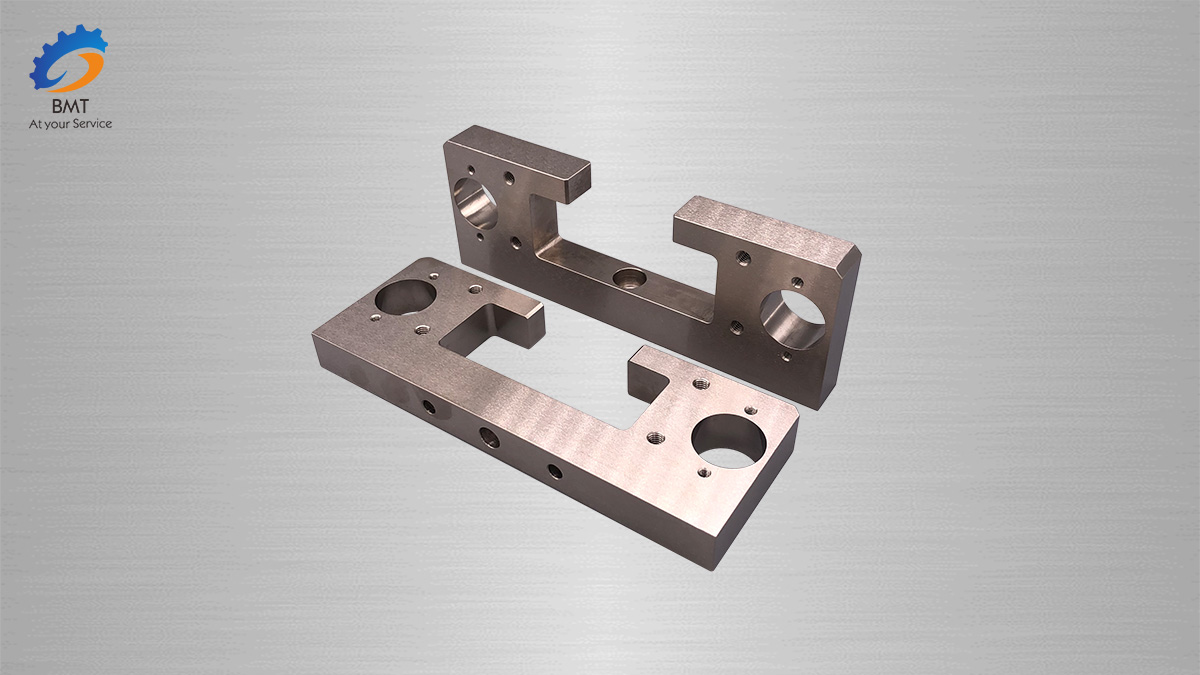

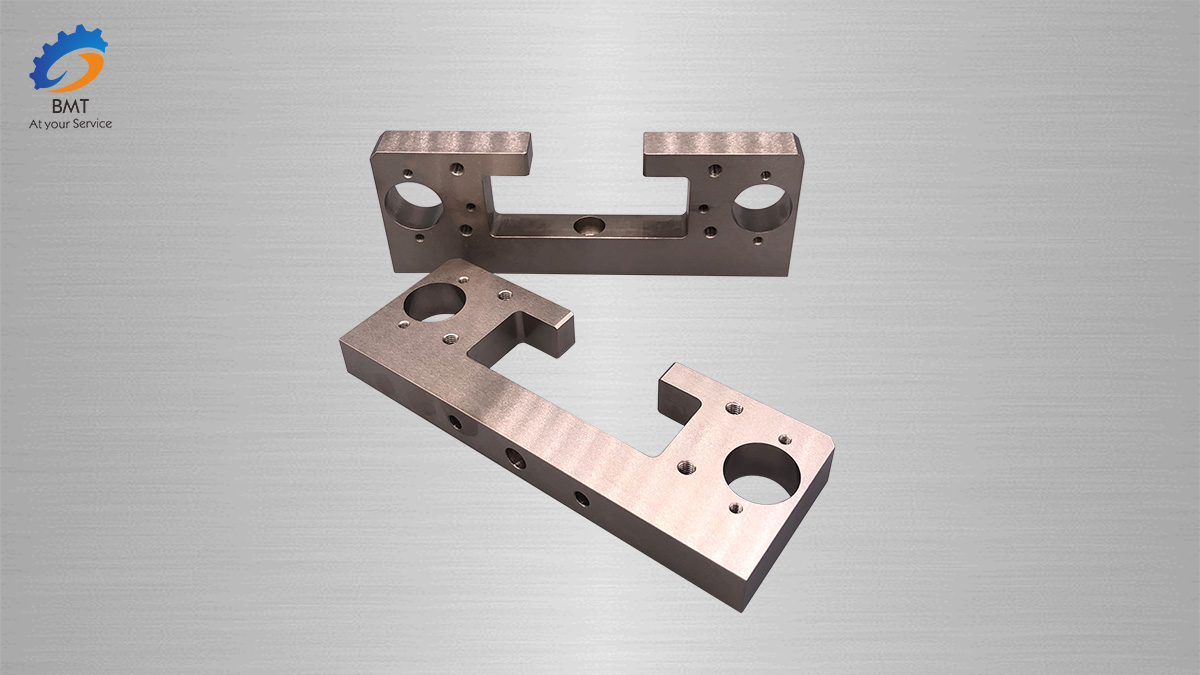

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes