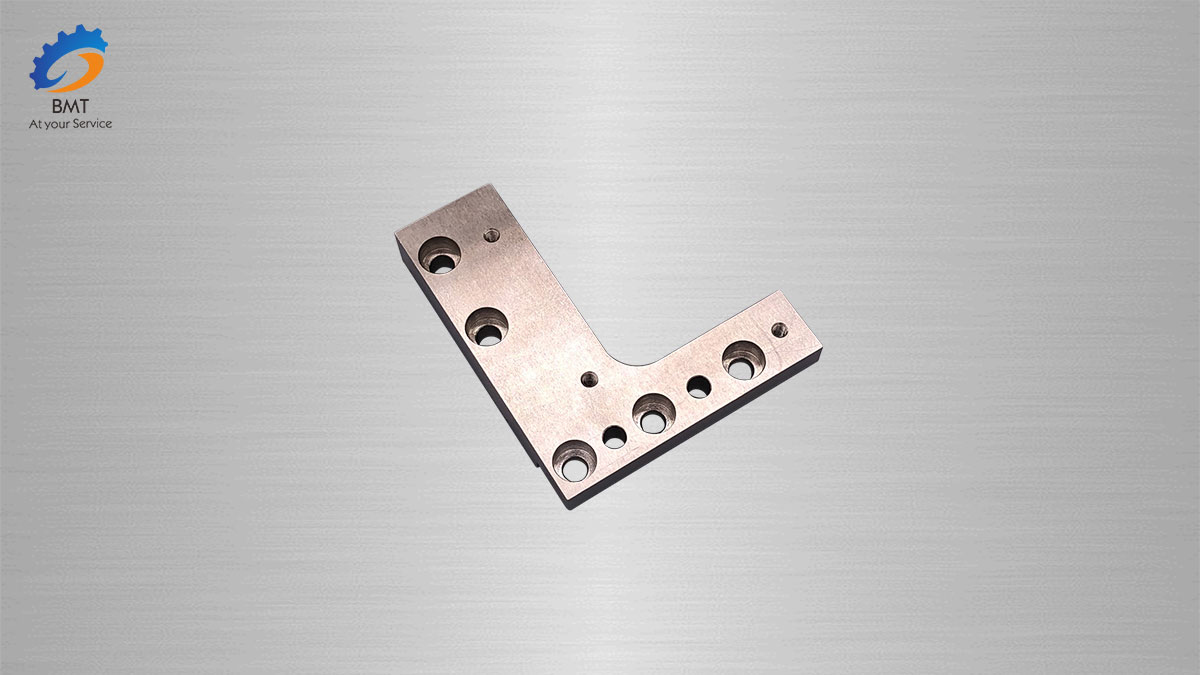

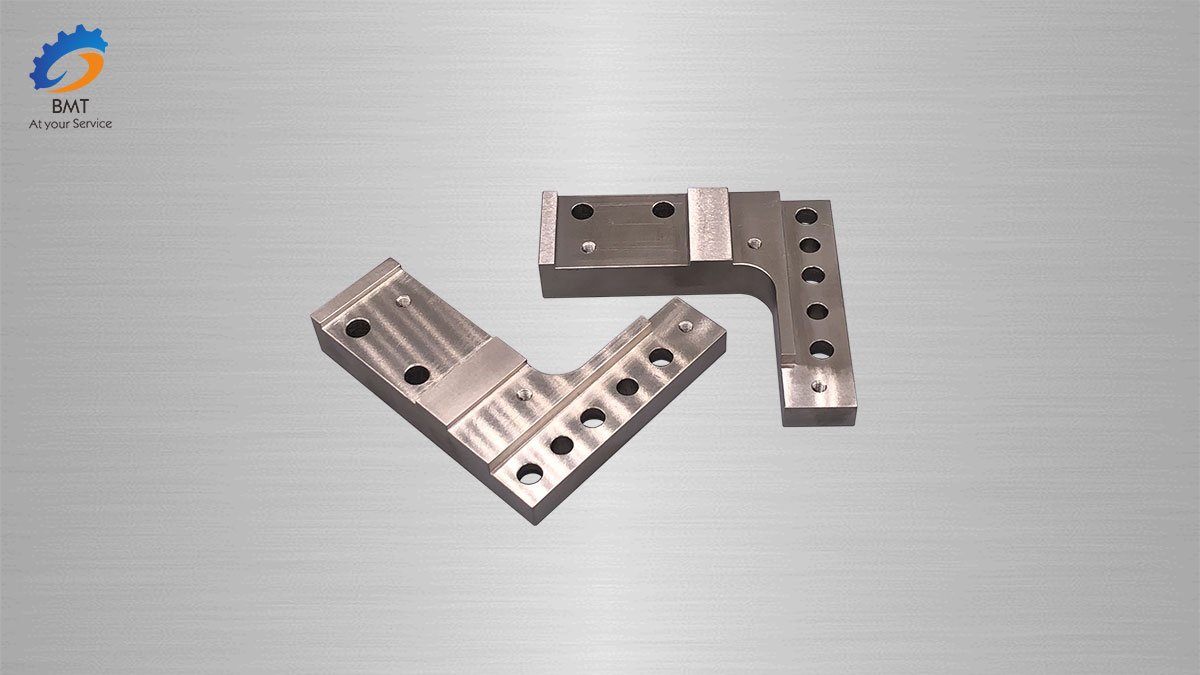

Kuskuren Guiderail

Jagora kuma yana ɗaya daga cikin kuskuren kayan aikin injin, kuskuren kayan aikin injin, jagorar dogo yana da alhakin ƙayyade matsayin dangi na sassan kayan aikin na'ura, da daidaitaccen titin, da zarar ya bayyana matsala, don haka wurin da sassan ke cikin injin. Kuskuren kayan aiki zai faru kuma saboda haka za'a shafi daidaiton mashin ɗin. Gabaɗaya, kuskuren jagora yafi wanzuwar daidaitaccen digiri na murdiya, sirdi, kuskuren ganga, kuskuren madaidaiciyar madaidaiciyar madaidaiciya, kuskuren madaidaiciyar hanyoyi da yawa, kamar murdiya daidaici tana nufin layin jagora na gaba da na baya daga layi ɗaya; Kuskuren sirdi na baya-baya ne mai dogo mai jagora, layin dogo yana fitowa da kuskuren ganga, duka nau'in canjin siffar dogo ne; Kuma madaidaiciya da matakin da kuma kuskuren madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciyar hanya ita ce lankwasawa ta hanyar dogo a tsaye, lankwasa ta gefe.

Kuskuren Sarkar Watsawa

Sarkar watsawa na babban aikin shine don sarrafa juyawa na kayan aiki da kayan aiki, a cikin abin da akwai sassa masu motsi da yawa, idan waɗannan abubuwan da aka gyara sun bayyana kuskure yayin masana'anta, taro, ko kuma a cikin aiwatar da amfani da lalacewa da tsagewa, don haka rabo dangantaka tsakanin kayan aiki da workpiece za su shafi, sabili da haka rinjayar machining daidaito.

Nakasar Danniya

A cikin aiwatar da mashin ɗin, tsarin injin ɗin zai kasance kowane nau'in ƙarfi, kamar ƙarfin centrifugal, yanke ƙarfi da sauransu, waɗannan ƙarfi a cikin kayan aikin tuki, kayan aiki, jigs da sauran cikakkun ayyukan sarrafawa, a lokaci guda kuma. yana shafar sauran abubuwan da aka gyara, saurin motsi, wanda ke haifar da raguwar daidaiton injin. Alal misali, lokacin da yanke kayan aiki a cikin tsarin mashin ɗin ya shafi ƙarfin centrifugal, ƙaddamarwar yankan asali na asali zai faru kuma aiki da kayan tarihi da ke haifar da rawar jiki mai sauri da kuma yanke fuska na sassa na inji zai bayyana kuskure.

Kayan Aikin Na'ura, Nakasar Zazzabi na Yanke

Tsarin sarrafa sassa na injina na sassa daban-daban na wasanni masu saurin gudu suna haifar da rikici mai sauri tsakanin sassa ko sassan tare da iska, sannan kuma suna haifar da zafi mai yawa, kuma a ƙarƙashin tasirin zafi mai tsananin sanyi, tsarin injin zai bayyana daban-daban. digiri na nakasar thermal kuma, bi da bi, yana shafar daidaiton mashin ɗin, abin da ke faruwa a cikin kayan aikin injin, kayan aikin yankan, Kayan aiki sun zama ruwan dare gama gari, lokacin da nakasar kayan aikin injin, akwatin sandal da layin jagora zai iya bayyana. nakasawa, lankwasawa, haifar da kuskuren jagora da kuskuren sandal.

Kuma lokacin da akwai kayan aikin nakasa mai zafi, ƙarar sa za ta ci gaba da canzawa a cikin wani kewayon, kuma sarrafa girman sassan injina masu girma dabam zai faru. Bugu da kari, thermal nakasawa na workpiece zai shafi ƙarar wani workpiece, ko da yake wani canji da cewa ba zai kai tsaye shafi siffar, amma idan workpiece ne mai tsanani unevenly, don haka shi a kan aiwatar da nakasawa kuma zai iya haifar da ciki danniya daga. ciki, da kuma na ciki danniya zai zama kamar yadda surface na karfe workpiece excision da na ciki redistribution a cikin kayan tarihi, sa kayan tarihi bayyana a fili nakasawa, da kuma bayan workpiece nakasawa , inji sassa sarrafa daidaici yanayi kuma rage.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes