Muna ƙoƙari don nagarta, hidimar abokan ciniki", yana fatan zama mafi kyawun haɗin gwiwar ma'aikata da mallake kamfani ga ma'aikata, masu kaya da masu siyayya, gano ƙimar farashin da ci gaba da tallan don masana'anta kai tsaye samar da Mashin Mashin ɗin Sin na CNC don Abubuwan Sensor ta Titanium Alloy da Medical Kayayyakin simintin gyare-gyare, A halin yanzu, muna ci gaba da neman ƙarin haɗin gwiwa tare da abubuwan da ke waje waɗanda aka ƙaddara ta hanyar fa'idodin juna. Da fatan za a sami kyauta don tuntuɓar mu don ƙarin bayanai.

Muna ƙoƙari don nagarta, sabis na abokan ciniki", yana fatan zama mafi kyawun haɗin gwiwar ma'aikata da mamaye kamfani don ma'aikata, masu kaya da masu siyayya, gano ƙimar farashin da ci gaba da tallan don tallatawa.China CNC Machine, Injin Yankan, Kamfaninmu yana bin dokoki da ayyukan duniya. Mun yi alkawarin zama alhakin abokai, abokan ciniki da duk abokan tarayya. Muna so mu kafa dangantaka na dogon lokaci da abota tare da kowane abokin ciniki daga ko'ina cikin duniya bisa ga fa'idodin juna. Muna maraba da duk tsofaffi da sababbin abokan ciniki don ziyartar kamfaninmu don yin shawarwarin kasuwanci.

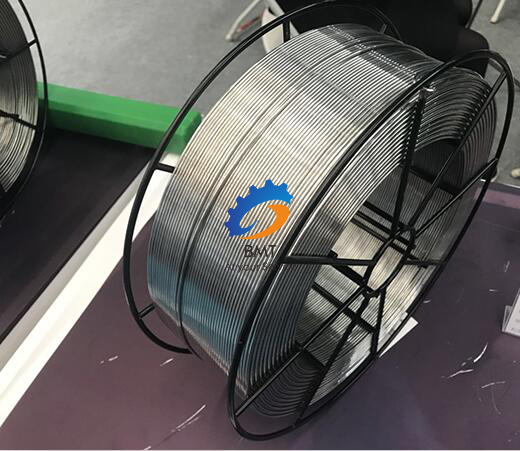

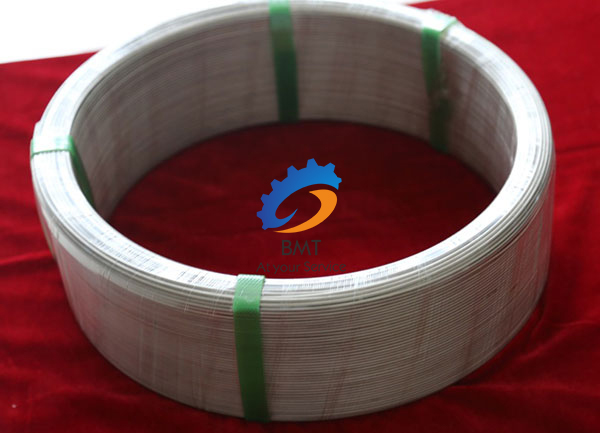

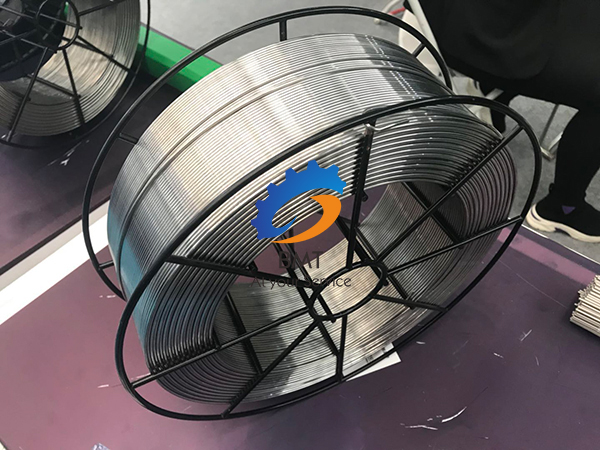

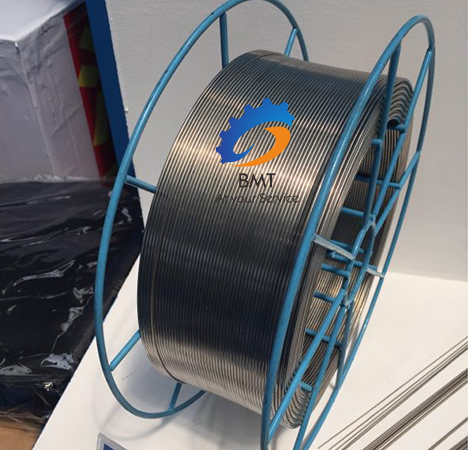

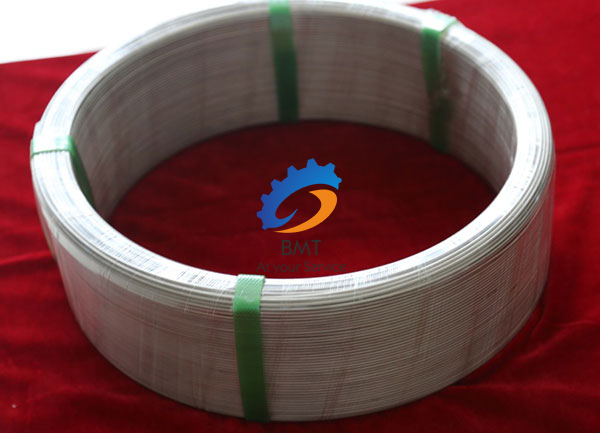

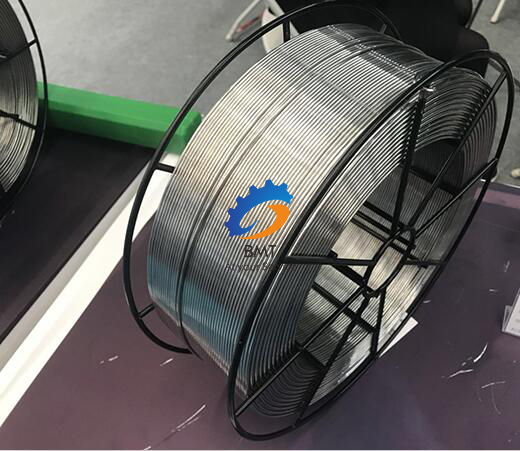

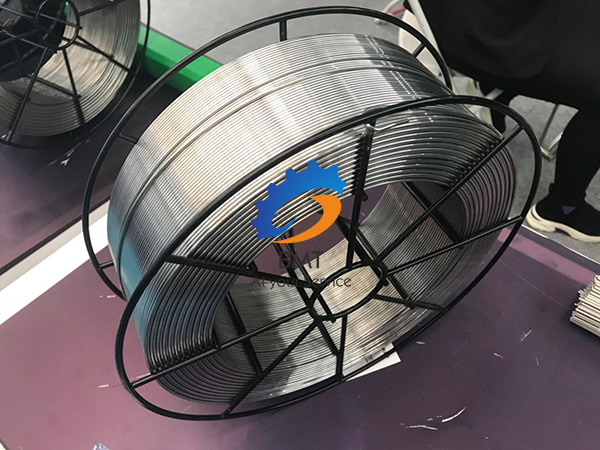

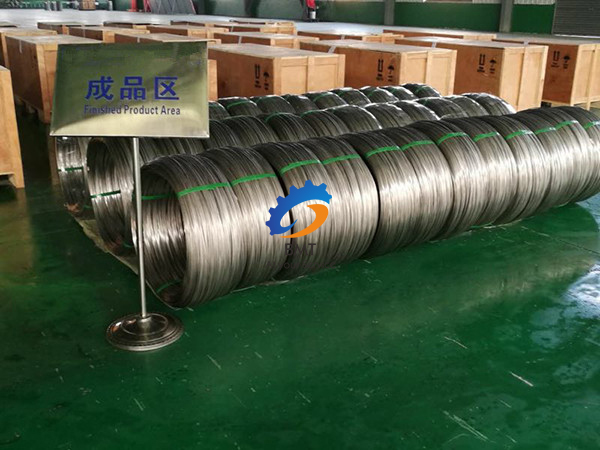

Titanium da Titanium Alloy Wires

Tsaftataccen titanium farin ƙarfe ne na azurfa, wanda ke da kyawawan kaddarorin. Titanium yana da yawa na 4.54g/cm3, 43% haske fiye da karfe kuma dan kadan ya fi nauyi fiye da babban ƙarfe magnesium mai haske. Amma ƙarfin injin yana kusan daidai da ƙarfe, ƙarfin ƙarfin aluminum sau biyu kuma ya fi magnesium ƙarfi sau biyar. Titanium yana da juriya ga zafin jiki kuma yana da wurin narkewa na 1942K, kusan 1000K ya fi zinari kuma kusan 500K ya fi karfe.

Titanium waya ya kasu kashi: titanium waya, titanium alloy waya, tsantsa titanium eyeglass waya, titanium madaidaiciya waya, tsantsa titanium waya, titanium waldi waya, titanium rataye waya, titanium faifai waya, titanium haske waya, likita titanium waya, titanium nickel alloy waya .

Ƙayyadaddun Waya Titanium

A. Titanium waya bayani dalla-dalla: φ0.8-φ6.0mm

B. Gilashin titanium waya bayani dalla-dalla: φ1.0-φ6.0mm musamman titanium waya

C. Bayanan waya na Titanium: φ0.2-φ8.0mm tare da rataye na musamman

Daidaito:GB/T, GJB, AWS, ASTM, AMS, JIS

Babban darajar Titanium Wire

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, da dai sauransu.

Filin Aikace-aikacen Waya Titanium

Masana'antar soji, likitanci, kayan wasanni, gilashin, 'yan kunne, tufafin kai, rataye na lantarki, wayar walda da sauran masana'antu.

Jihar Titanium Wire

Halin da ake ciki (M)

Yanayin aiki mai zafi (R)

Yanayin aiki sanyi (Y)

(Annealing, Gwajin-ƙarar-ƙarni)

Surface na Titanium Wire

Pickling surface ko haske surface

Wayar titanium tana samar da karbuwa barga tare da taurin mafi girma tare da carbon. Girman Layer na carbonized tsakanin titanium da carbon an ƙaddara ta hanyar yaduwar adadin titanium a cikin Layer carbonized.

Solubility na carbon a titanium kadan ne, wanda ya kai 0.3% a 850X: kuma yana raguwa zuwa kusan 0.1% a 600C B Saboda ƙarancin solubility na carbon a cikin titanium, taurin saman yana samuwa ne kawai ta hanyar titanium carbide Layer da akimbo. Layer kasa. Carburizing dole ne a za'ayi a karkashin yanayin cire oxygen, saboda surface Layer taurin foda da aka saba amfani da carburizing karfe a kan saman carbon monoxide ko oxygen-dauke da carbon monoxide ne har zuwa 2700MPa da 8500MPa, da raga. Yana da sauƙin kwasfa.

Samfuran Haɗin Sinadarin Kayan Abu

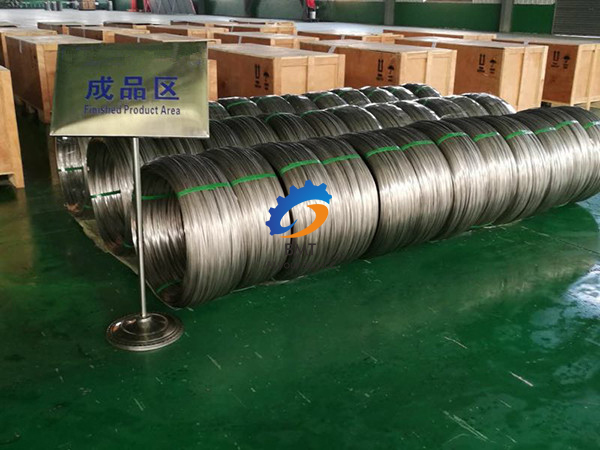

Yawan aiki (Max da Min adadin oda):Unlimited, bisa ga tsari.

Lokacin Jagora:Gaba ɗaya lokacin jagoran shine kwanaki 30. Duk da haka, ya dogara da adadin odar bisa yarda.

Sufuri:Babban hanyar sufuri ita ce ta Teku, ta Air, ta Express, ta Train, wanda abokan ciniki za su zaɓa.

Shiryawa:

- Ƙarshen bututu don a kiyaye shi da filaye ko kwali.

- Duk kayan aikin da za'a shirya don kare iyaka da fuskantar.

- Duk sauran kayayyaki za a cika su ta hanyar kumfa mai kumfa da marufi masu alaƙa da filastik da lamunin plywood.

- Duk wani itace da aka yi amfani da shi don tattarawa dole ne ya dace don hana gurɓatawa ta hanyar tuntuɓar kayan aiki.

.jpg)

Sabanin haka, a ƙarƙashin yanayin deoxygenation ko decarburization, za a iya samar da wani bakin ciki Layer na titanium carbide lokacin da carburized a cikin gawayi. Taurin wannan Layer shine 32OUOMPa, wanda yayi daidai da taurin titanium carbide. Zurfin carburizing Layer gabaɗaya ya fi na nitriding Layer yayin da ake amfani da nitriding a ƙarƙashin yanayi iri ɗaya. A ƙarƙashin yanayin haɓakar iskar oxygen, dole ne a yi la'akari da tasirin iskar oxygen akan zurfin taurin. Sai kawai a ƙarƙashin yanayin kauri na bakin ciki sosai cewa isassun ƙarfin mannewa za'a iya samuwa ta hanyar carburizing foda na carbon a cikin injin daskarewa ko a cikin yanayin argon-methane. Sabanin haka, yin amfani da wakili na iskar gas na iya haifar da taurare mai taurare mai tauri mai ƙarfi da kyau da kyau. A lokaci guda, da hardening baza kafa a zazzabi tsakanin 950T: da kuma 10201:. Tare da karuwar kaurin Layer, TiC Layer ya zama mafi gatsewa kuma yana ƙoƙarin yashewa. Don guje wa kutsawa na hada carbon cikin Layer TiC saboda rugujewar Reane, iskar gas ya kamata a gudanar da shi a cikin iskar da ba ta dace ba tare da ƙayyadaddun ƙarar kashi 2% na Reane. Ana samun ƙananan taurin ƙasa lokacin da methane ya zama carburized tare da ƙari na propane. Lokacin da ƙarfin haɗin kai ya kai OKPA kuma ana amfani da iskar gas carburized propane, kodayake ma'aunin kauri mai ƙarfi yana da bakin ciki sosai, yana da mafi kyawun juriya. Ana shayar da hydrogen ta hanyar wakili na carburizing gas, amma dole ne a sake cire shi a lokacin haɓakawa. Muna ƙoƙari don haɓakawa, sabis na abokan ciniki ", yana fatan ya zama mafi kyawun haɗin gwiwar ma'aikata da mamaye kamfani don ma'aikata, masu kaya da masu siyayya, ya fahimci rabon farashin. da kuma ci gaba da tallace-tallace ga Factory kai tsaye samar da China daidaici Machining CNC ga Sensor aka gyara ta Titanium Alloy da Medical Die simintin Products, A halin yanzu, muna neman gaba har ma mafi girma hadin gwiwa tare da kasashen waje al'amurra ƙaddara ta juna amfanin. Da fatan za a sami kyauta don tuntuɓar mu don ƙarin bayanai.

Factory Kai tsaye wadataChina CNC Machine, Injin Yankan, Kamfaninmu yana bin dokoki da ayyukan duniya. Mun yi alkawarin zama alhakin abokai, abokan ciniki da duk abokan tarayya. Muna so mu kafa dangantaka na dogon lokaci da abota tare da kowane abokin ciniki daga ko'ina cikin duniya bisa ga fa'idodin juna. Muna maraba da duk tsofaffi da sababbin abokan ciniki don ziyartar kamfaninmu don yin shawarwarin kasuwanci.