Rarraba Injinan Niƙa

Tare da karuwar adadinhigh-daidaicida high taurin inji sassa, kazalika da ci gaban madaidaicin simintin gyaran kafa da kuma daidai ƙirƙira fasaha, yi, iri-iri da kuma fitarwa na nika inji suna kullum inganta da girma.

(1) Silindrical grinder:Yana da asali jerin talakawa nau'i, yafi amfani da shi don nika cylindrical da conical waje saman.

(2) Mai niƙa na ciki:Silsilar nau'in tushe ce ta gama gari, galibi ana amfani da ita don niƙa cylindrical da filaye na ciki.

(3) Mai sarrafa niƙa:ciki grinder tare da daidaita daidaita na'urar sakawa.

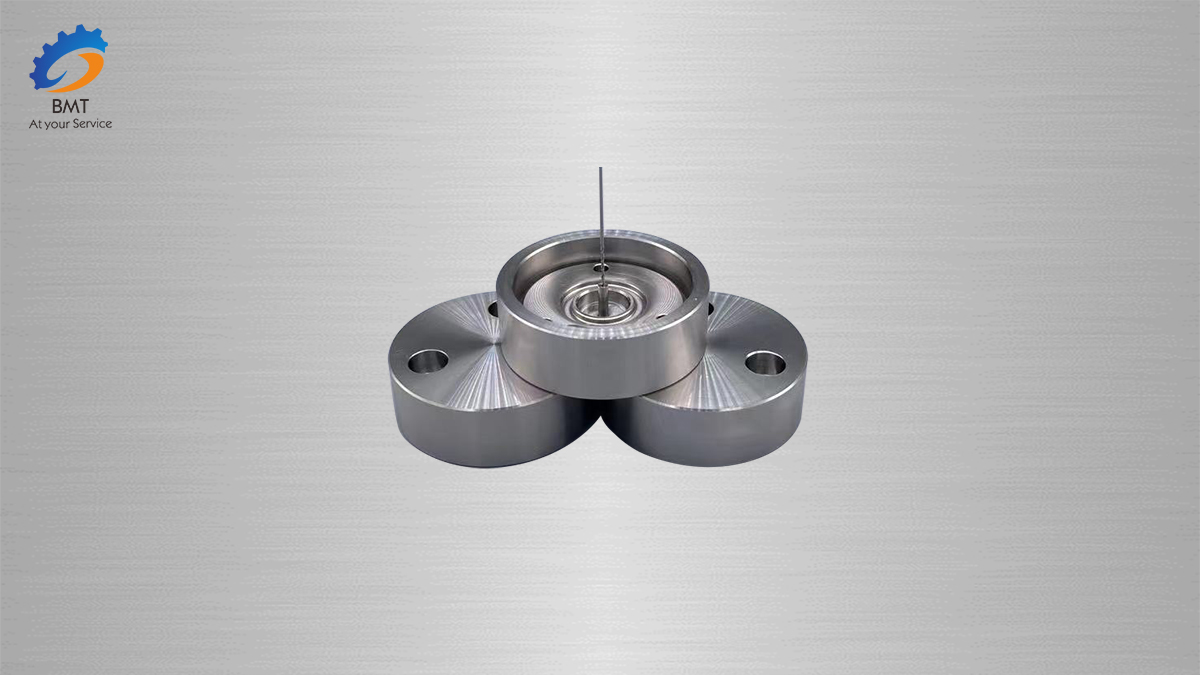

(4) Mai niƙa mara ƙima:The workpiece an clampedless tsakiya, gaba ɗaya goyan bayan tsakanin dabaran jagora da sashi, kuma dabaran jagora yana korar workpiece don juyawa. An fi amfani dashi don niƙa saman cylindrical.

(5) Na'ura mai niƙa: yafi amfani da nika surface na workpiece.

(6) Mai niƙa mai ƙyalli:Injin niƙa da ke amfani da bel ɗin ƙura da sauri don niƙa.

(7) Na'ura mai ɗaukar nauyi:Ana amfani da shi don honing daban-daban saman na workpieces.

(8) Mai niƙa:Ana amfani da shi don niƙa ciki da waje saman jirgin saman workpiece ko Silinda.

(9) Jagoran injin niƙa:yafi amfani da nika jagora dogo surface na inji kayan aiki.

(10) Kayan aikin niƙa:An yi amfani da injin niƙa don kayan aikin niƙa.

(11) Multi manufa inji nika:Ana amfani dashi donnika cylindricalda kuma filaye na ciki da na waje ko jirage, kuma suna iya amfani da na'urorin servo da na'urorin haɗi don niƙa nau'ikan kayan aiki iri-iri.

(12) Injin niƙa na musamman:na'ura ta musamman da ake amfani da ita don niƙa wasu nau'ikan sassa. Dangane da abubuwan da ake sarrafa shi, ana iya raba shi zuwa maƙalar spline shaft grinder, crankshaft grinder, cam grinder, gear grinder, thread grinder, curve grinder, da dai sauransu.

Kariyar Tsaro

Nikaana amfani da shi sosai kuma yana ɗaya daga cikin manyan hanyoyin da ake yin daidaitaccen injin sassa na inji. Duk da haka, saboda tsananin gudun injin niƙa na niƙa, injin niƙa yana da wuya, gaggautuwa, kuma ba zai iya jurewa tasiri mai nauyi ba. Yin aiki mara kyau na lokaci-lokaci zai haifar da mummunan sakamako idan injin niƙa ya karye. Sabili da haka, aikin fasaha na aminci na niƙa yana da mahimmanci musamman. Dole ne a yi amfani da na'urorin kariya masu aminci, kuma aikin dole ne a mai da hankali don tabbatar da cewa babu haɗari.Bugu da ƙari, ƙananan yashi mai kyau da guntuwar ƙarfe da aka fantsama daga aikin injin niƙa yayin niƙa zai cutar da idanun ma'aikata. Idan ma’aikata suka shaka wannan kura mai yawa, hakan zai yi illa ga lafiyarsu, sannan a dauki matakan kariya da suka dace. Ya kamata a kula da matsalolin fasaha na aminci masu zuwa yayin niƙa.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes