Titanium Alloy Welding

Garin lokaci ɗaya ne wanda ya ƙunshi β-phase m bayani. Ba tare da maganin zafi ba, yana da ƙarfi mafi girma. Bayan quenching da tsufa, gami yana ci gaba da haɓakawa. Mataki ɗaya ƙarfafawa, ƙarfin zafin jiki na ɗakin zai iya kaiwa 1372 ~ 1666 MPa; Amma kwanciyar hankali na thermal ba shi da kyau, bai kamata a yi amfani da shi a babban zafin jiki ba.

Yana da nau'i mai nau'i na biphasic, yana da kyawawan kaddarorin mahimmanci, kyakkyawan tsarin kwanciyar hankali, mai kyau tauri, filastik da ƙananan lalacewar yanayin zafi, zai iya zama mafi kyau don sarrafa matsa lamba, ana iya kashewa, tsufa don ƙarfafa gami. Ƙarfin bayan maganin zafi yana kusan 50% ~ 100% mafi girma fiye da haka bayan annealing; High zafin jiki ƙarfi, iya aiki a 400 ℃ ~ 500 ℃ zafin jiki na dogon lokaci, ta thermal kwanciyar hankali ne m zuwa α titanium gami.

Daga cikin nau'ikan titanium guda uku, waɗanda aka fi amfani da su sune α titanium alloy da α + β titanium alloy; Yanke aikin α titanium alloy shine mafi kyawun, sannan α + β titanium gami da β titanium alloy shine mafi muni. α titanium alloy code don TA, β titanium alloy code don TB, α + β titanium alloy code don TC.

Titanium gami za a iya raba zafi resistant gami, high ƙarfi gami, lalata resistant gami (titanium - molybdenum, titanium - palladium alloy, da dai sauransu), low zafin jiki gami da musamman aiki gami (titanium - baƙin ƙarfe hydrogen ajiya kayan da titanium - nickel memory. alloy). Ana nuna abun da ke ciki da kaddarorin na al'ada a cikin tebur.

Za'a iya samun nau'ikan nau'ikan lokaci daban-daban da microstructure na gami da kayan aikin titanium da aka bi da su ta hanyar daidaita tsarin kula da zafi. An yi imani da cewa kyawawan sifofin da aka daidaita suna da mafi kyawun filastik, kwanciyar hankali na zafi da ƙarfin gajiya. Tsarin spiculate yana da tsayi mai tsayi, ƙarfi mai raɗaɗi da taurin karaya. Haɗaɗɗen kyallen takarda masu daidaita daidai da allura kamar allura suna da ingantattun kaddarorin. Titanium wani sabon nau'in karfe ne, aikin titanium yana da alaƙa da abun ciki na carbon, nitrogen, hydrogen, oxygen da sauran ƙazanta, mafi ƙarancin titanium iodide najasa bai wuce 0.1% ba, amma ƙarfinsa kaɗan ne, babban filastik. .

Kaddarorin 99.5% titanium mai tsabta kamar haka: yawa ρ = 4.5g / cubic cm, narkewar maki 1725 ℃, thermal conductivity λ = 15.24W / (mK), tensile ƙarfi σb = 539MPa, elongation δ = 25%, sashe shrinkage ψ=25%, E = 1.078×105MPa, taurin HB195. The yawa na titanium gami ne kullum game da 4.51g/ cubic santimita, kawai 60% na karfe, da ƙarfi na tsarki titanium ne kusa da ƙarfin talakawa karfe, wasu high ƙarfi titanium gami ya zarce ƙarfin da yawa gami tsarin karfe. Saboda haka, ƙayyadaddun ƙarfin (ƙarfi / yawa) na titanium alloy ya fi girma fiye da na sauran kayan aikin ƙarfe, kamar yadda aka nuna a cikin Table 7-1. Yana iya samar da sassa da sassa tare da babban ƙarfin naúrar, mai kyau rigidity da haske nauyi. A halin yanzu, ana amfani da alluran titanium a cikin kayan injin, kwarangwal, fata, kayan ɗamara da kayan saukarwa.

Aiko mana da sakon ku:

-

Aluminum CNC Machining Parts

-

Aluminum Sheet Metal Fabrication

-

Axis High Precision CNC Machining Parts

-

CNC Machined Parts don Italiya

-

CNC Machining Aluminum Parts

-

Injiniyan Kayan Mota

-

Titanium Alloy Forgings

-

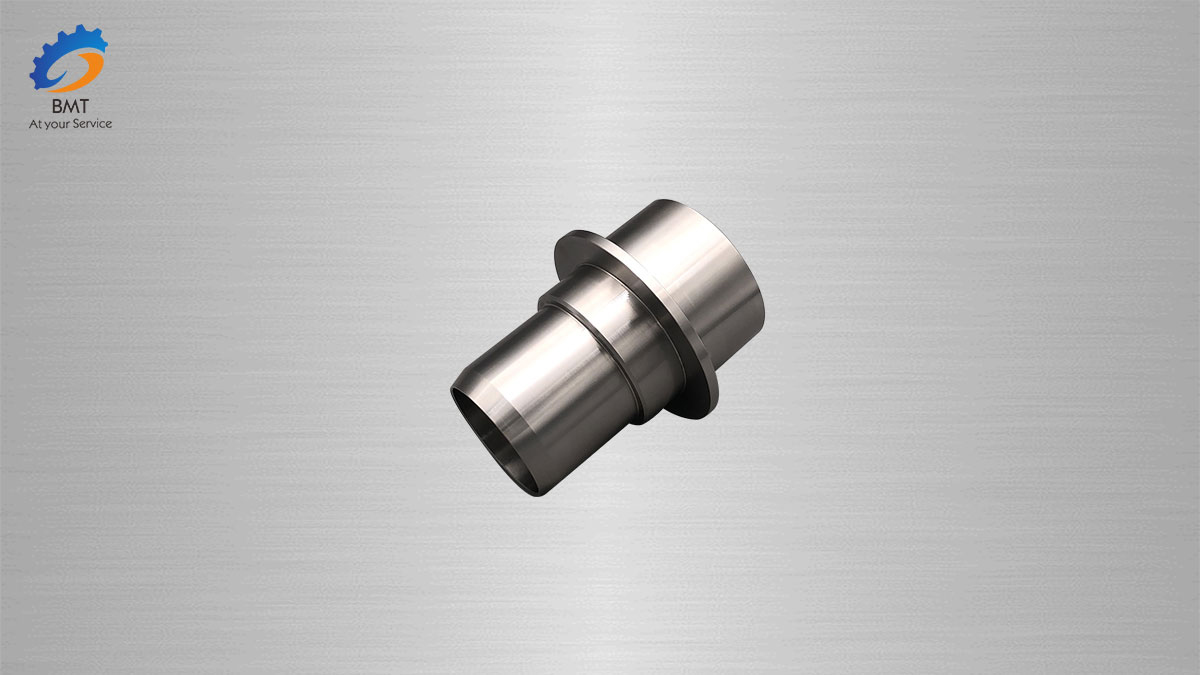

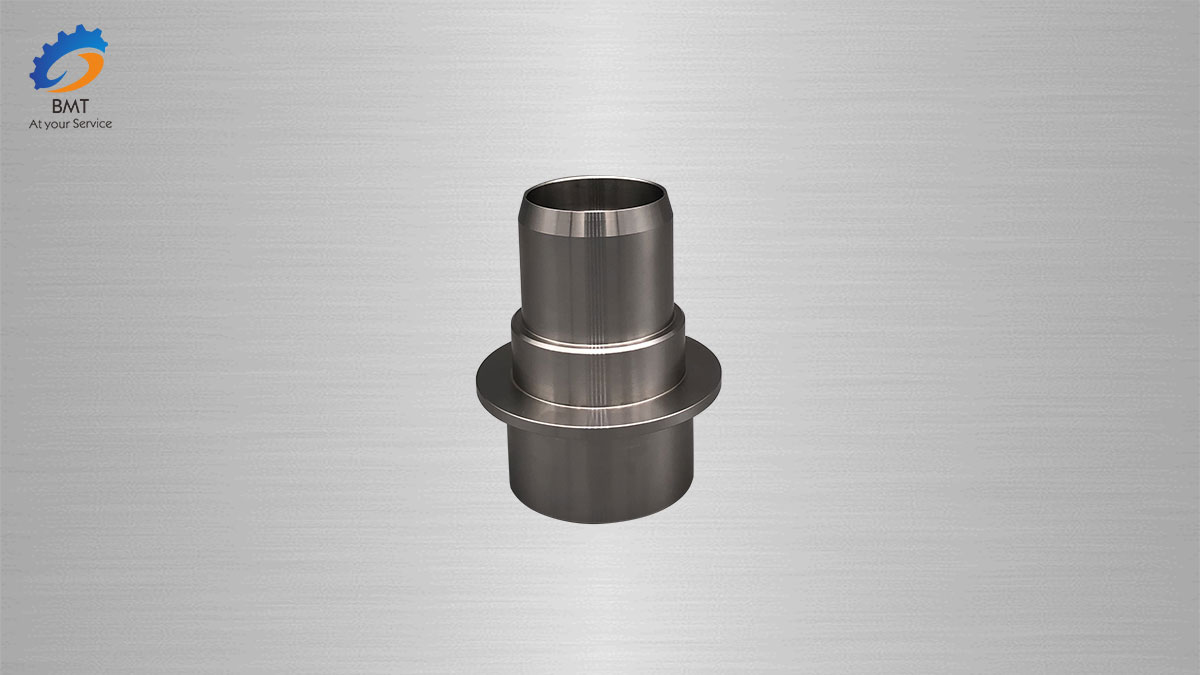

Titanium da Titanium Alloy Fittings

-

Titanium da Titanium Alloy Forgings

-

Titanium da Titanium Alloy Wires

-

Titanium Bars

-

Titanium Bututu mara kyau / Tubu

-

Titanium Welded Pipes/Tubes