Titanium Bututu da Bututu maras kyau

Gr1, Gr 2, Gr 3 duk masana'antu ne mai tsabta titanium. Suna da manyan kaddarorin inji, kyakkyawan aikin hatimi, kuma ana iya walda su ta nau'i daban-daban. Ƙarfin haɗin gwiwa na welded zai iya kaiwa 90% na ƙarfin ƙarfe na tushe, kuma aikin yankan yana da kyau. Titanium bututu yana da babban juriya ga chloride, sulfide da ammonia. Juriya na lalata titanium a cikin ruwan teku ya fi na aluminium alloys, bakin karfe, da alluran tushen nickel. Titanium kuma yana da juriya ga tasirin ruwa.

Ana amfani da alluran Titanium musamman don kera injin kwampreso na jirgin sama, sai kuma sassan tsarin roka, makamai masu linzami da kuma jiragen sama masu sauri. A tsakiyar shekarun 1960, an yi amfani da titanium da alluran sa a masana'antu gabaɗaya don kera na'urorin lantarki a cikin masana'antar lantarki, na'urori masu sarrafa wutar lantarki, na'urori masu dumama don tace mai da tsabtace ruwan teku, da na'urorin sarrafa gurɓataccen muhalli. Titanium da kayan aikin sa sun zama nau'in kayan gini masu jure lalata. Bugu da ƙari, ana amfani da ita wajen samar da kayan ajiyar hydrogen da sifofin ƙwaƙwalwar ajiya.

Idan aka kwatanta da sauran kayan ƙarfe, titanium gami yana da fa'idodi masu zuwa:

- Ƙarfin ƙayyadaddun ƙayyadaddun ƙarfi (ƙarfin ƙarfi / yawa), ƙarfin ƙarfi na iya kaiwa 100 ~ 140kgf / mm2, kuma yawancin shine kawai 60% na karfe.

- Matsakaicin zafin jiki yana da ƙarfi mai kyau, yawan zafin jiki na amfani yana da digiri ɗari da yawa sama da na alloy na aluminum, har yanzu yana iya kiyaye ƙarfin da ake buƙata a matsakaicin zafin jiki, kuma yana iya aiki na dogon lokaci a zazzabi na 450 ~ 500 ℃.

- Kyakkyawan juriya na lalata. An samar da fim ɗin uniform kuma mai yawa oxide nan da nan akan saman titanium a cikin yanayi, wanda ke da ikon tsayayya da lalata ta kafofin watsa labarai daban-daban. Gabaɗaya, titanium yana da juriya mai kyau a cikin oxidizing da watsa labarai masu tsaka tsaki, kuma yana da mafi kyawun juriya na lalata a cikin ruwan teku, jikarin chlorine da chloride mafita. Amma a rage kafofin watsa labarai, irin su hydrochloric acid da sauran mafita, lalata juriya na titanium ba shi da kyau.

- Titanium alloys tare da kyakkyawan aikin ƙarancin zafin jiki da ƙananan abubuwan tsaka-tsaki, irin su Gr7, na iya kula da wani matakin filastik a -253 ℃.

- Modules na elasticity yana da ƙasa, ƙarancin zafin jiki yana ƙarami, kuma ba shi da ferromagnetic.

BMT ya kware wajen fitar da bututu da bututun titanium maras sumul, da kuma mallakar abin da ake samarwa a shekara na tan 5,000. BMT bututu maras kyau da bututu suna da takamaiman takamaiman ƙarfi, juriya na lalata, kyawawan kayan cryogenic, ƙarancin elasticity modulus, ƙarancin ƙarancin zafi kuma babu feromagnetism.

kewayon BMT na bututun titanium maras sumul da bututu suna siyarwa gabaɗaya a duniya. Ana aiwatar da ingantaccen kulawa cikin sharuddan inganci, gami da nazarin abubuwan sinadarai, gwajin matsa lamba na iska, gwaji mara lalacewa, gwajin eddy na yanzu da gwajin ultrasonic. Har ila yau, muna da gwajin injina, gwajin gwaji mai rufewa, gwajin flaring, gwajin fa'ida, gwajin ferroxyl, gwajin RT, gwajin X-Ray, da sauransu.

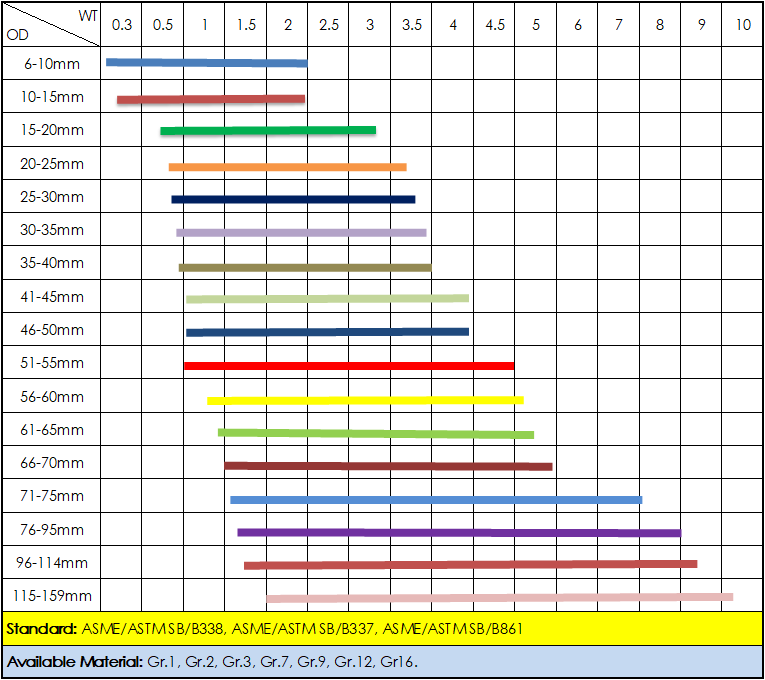

Titanium Bututu maras kyau da Girman Tubus:

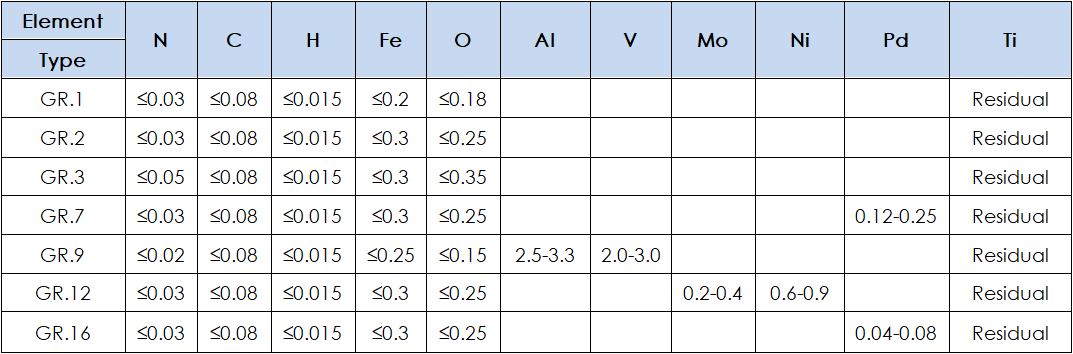

Samfuran Haɗin Sinadarin Abu:

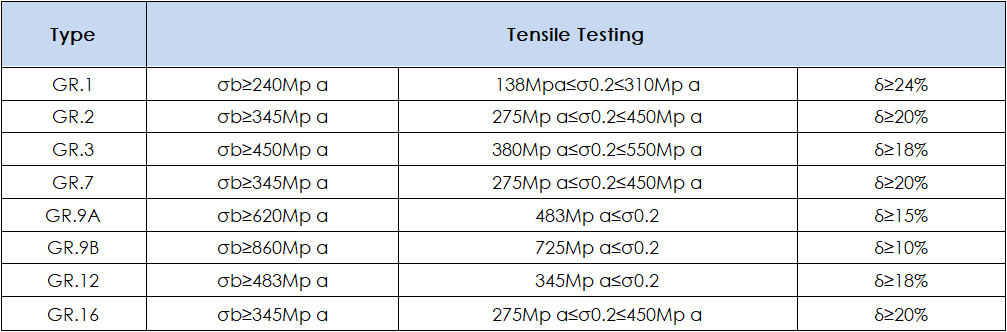

Samfuran Kayan Kayan Kayan Kayan Kayan Abinci:

Gwajin dubawa:

- Binciken Haɗin Sinadari

- Gwajin Kayayyakin Injini

- Gwajin tensile

- Gwajin Flaring

- Gwajin Lalacewa

- Lankwasawa Gwajin

- Gwajin Hydro-Static

- Gwajin huhu (Gwajin hawan iska a ƙarƙashin ruwa)

- Gwajin NDT

- Gwajin Eddy-Yanzu

- Gwajin Ultrasonic

- Gwajin LDP

- Gwajin Ferroxyl

Yawan aiki (Max da Min adadin oda):Unlimited, bisa ga tsari.

Lokacin Jagora:Gaba ɗaya lokacin jagoran shine kwanaki 30. Duk da haka, ya dogara da adadin odar bisa yarda.

Sufuri:Babban hanyar sufuri ita ce ta Teku, ta Air, ta Express, ta Train, wanda abokan ciniki za su zaɓa.

Shiryawa:

- Ƙarshen bututu don a kiyaye shi da filaye ko kwali.

- Duk kayan aikin da za'a shirya don kare iyaka da fuskantar.

- Duk sauran kayayyaki za a cika su ta hanyar kumfa mai kumfa da marufi masu alaƙa da filastik da lamunin plywood.

- Duk wani itace da aka yi amfani da shi don tattarawa dole ne ya dace don hana gurɓatawa ta hanyar tuntuɓar kayan aiki.