Titanium da Titanium Alloy Forgings

Titanium da titanium alloys suna da fa'idodin ƙarancin ƙima, ƙayyadaddun ƙarfi na musamman da juriya mai kyau, kuma ana amfani da su sosai a fannoni daban-daban.

Ƙirƙirar titanium wata hanya ce ta ƙirƙira wacce ke amfani da ƙarfi na waje zuwa ɓangarorin ƙarfe na titanium (Ban da faranti) don samar da nakasar filastik, canza girma, siffa, da haɓaka aiki. Ana amfani da shi don kera sassa na inji, kayan aiki, kayan aiki ko sarari. Bugu da ƙari, bisa ga tsarin motsi na maɗauri da tsarin motsi na tsaye da a kwance (Don ƙirƙira sassan siriri, lubrication da sanyaya, da ƙirƙira sassan samar da sauri), sauran hanyoyin motsi za a iya haɓaka ta hanyar. ta amfani da na'urar diyya.

Hanyoyin da ke sama sun bambanta, kuma ƙarfin ƙirƙira da ake buƙata, tsari, ƙimar amfani da kayan aiki, fitarwa, juriyar juzu'i, da lubrication da hanyoyin sanyaya suma sun bambanta. Waɗannan abubuwan kuma sune abubuwan da ke shafar matakin sarrafa kansa.

Ƙirƙira tsari ne na yin amfani da filastik na ƙarfe don samun tsari na ƙirƙirar filastik tare da wani nau'i da sifofi na tsarin da ba komai a ƙarƙashin tasiri ko matsa lamba na kayan aiki. Mahimmancin ƙirƙira na ƙirƙira shine cewa ba zai iya samun nau'ikan sassa na injin ba kawai, amma kuma yana haɓaka tsarin ciki na kayan aiki da haɓaka kayan aikin injiniya na sassan injin.

1. Kirkirar Kyauta

Ƙirƙirar ƙirƙira gabaɗaya ana aiwatar da ita tsakanin lebur biyu ko gyaggyarawa ba tare da rami ba. Kayan aikin da aka yi amfani da su a cikin ƙirƙira kyauta suna da sauƙi a cikin siffar, sassauƙa, gajere a cikin sake zagayowar masana'antu da ƙananan farashi. Duk da haka, ƙarfin aiki yana da yawa, aikin yana da wuyar gaske, yawan aiki ba shi da yawa, ingancin kayan aikin ƙira ba shi da yawa, kuma izinin injin yana da yawa. Sabili da haka, ya dace kawai don amfani lokacin da babu buƙatu na musamman akan aikin sassan kuma adadin ƙananan ƙananan.

2. Buɗe Die Forging (Die Forging with Burrs)

Wurin da babu komai ya ɓata tsakanin sifofi biyu tare da zane-zane, ƙirƙirar tana kulle a cikin rami, kuma ƙarafan da ya wuce gona da iri yana fitowa daga ƙunƙun tazarar da ke tsakanin su biyun ya mutu, yana haifar da ɓarna a kusa da ƙirjin. A ƙarƙashin juriya na mold da kewaye burrs, karfe da aka tilasta da za a danna a cikin siffar mold cavity.

3. Rufe ƙirƙira (Die Forging without Burrs)

A lokacin rufaffiyar ƙirar ƙirƙira, ba a samar da ɓarna mai jujjuyawa daidai da alkiblar motsin mutu. Ramin rufaffiyar ƙirƙira mutu yana da ayyuka guda biyu: ɗaya don ƙirƙirar fanko ne, ɗayan kuma don jagora ne.

4. Extrusion Mutu Forging

Yin amfani da hanyar extrusion don ƙirƙira mutu, akwai nau'ikan ƙirƙira iri biyu, extrusion gaba da baya extrusion. Extrusion mutu ƙirƙira iya kera daban-daban m da kuma m sassa, kuma zai iya samun forgings tare da high geometrical daidaici da kuma m tsarin ciki.

5. Multi-Directional Die Forging

Ana aiwatar da shi akan injin ƙirƙira mutun na jagora mai yawa. Baya ga naushi a tsaye da alluran toshewa, injin ɗin mutun-mutu mai ɗai-ɗai shima yana da filaye biyu a kwance. Hakanan ana iya amfani da mai fitar da shi don naushi. Matsin na'urar fitarwa ya fi na yau da kullun na injin lantarki. Don zama babba. A Multi-directional mutu ƙirƙira, da darjewa aiki a madadin da kuma a hade a kan workpiece daga tsaye da kuma a kwance kwatance, da kuma daya ko fiye perforation punches da ake amfani da su sa karfe kwarara daga waje daga tsakiyar kogon don cimma manufar ciko. rami.

6. Karya Raba

Don ƙirƙira manyan ingantattun ingantattun ingantattun ingantattun matsi akan matsi na hydraulic da ke akwai, ana iya amfani da hanyoyin ƙirƙira ɓangarori na mutuƙar ƙirƙira irin su ƙirƙirar ƙirƙirar kashi da farantin shim mutu ƙirƙira. Siffar hanyar ƙirar ƙirƙira ta ɓarna ita ce aiwatar da ƙirƙira yanki guda ɗaya, sarrafa sashe ɗaya a lokaci guda, don haka ton kayan aikin da ake buƙata na iya zama ƙanƙanta. Gabaɗaya magana, ana iya amfani da wannan hanyar don aiwatar da manyan juzu'i a kan matsi na ruwa masu matsakaicin girma.

7. Isothermal Die Forging

Kafin yin ƙirƙira, ana yin zafi da ƙirƙira zuwa zafin ƙirƙira na blank, kuma zafin jiki na ƙirƙira da blank ɗin ya kasance iri ɗaya a cikin tsarin ƙirƙira, ta yadda za a iya samun babban adadin nakasar a ƙarƙashin aikin ɗan ƙaramin ƙarfi. . Isothermal die forging da isothermal superplastic die forging sun yi kama da juna, bambancin shi ne cewa kafin ya mutu, ana bukatar a sanya blank ɗin superplasticized [i] don ya zama yana da daidaitattun hatsi [ii].

Titanium alloy ƙirƙira tsari da ake amfani da ko'ina a cikin jirgin sama da kuma Aerospace masana'antu (Isothermal Die Forging Processan yi amfani da shi wajen kera sassan injina da sassan tsarin jirgin sama), kuma yana ƙara yin fice a sassan masana'antu kamar motoci, wutar lantarki, da jiragen ruwa.

A halin yanzu, farashin amfani da kayan titanium yana da tsada sosai, kuma yawancin filayen farar hula ba su da cikakkiyar masaniyar laya ta gami da titanium. Tare da ci gaba da ci gaban kimiyya, shirye-shiryen fasahar samfurin titanium da titanium zai zama mafi sauƙi kuma farashin sarrafawa zai kasance ƙasa da ƙasa, kuma za a ba da fifikon fara'a na titanium da titanium gami a cikin fa'idodi da yawa.

UsiHanyar extrusion don ƙirƙira ƙirƙira, akwai nau'ikan ƙirƙira nau'ikan ƙirƙira guda biyu, Extrusion Gaba da Reverse Extrusion. Extrusion Die Forging na iya kera sassa daban-daban masu fa'ida da ƙarfi, kuma yana iya samun ƙirƙira tare da madaidaicin juzu'i da tsarin ciki mai zurfi.

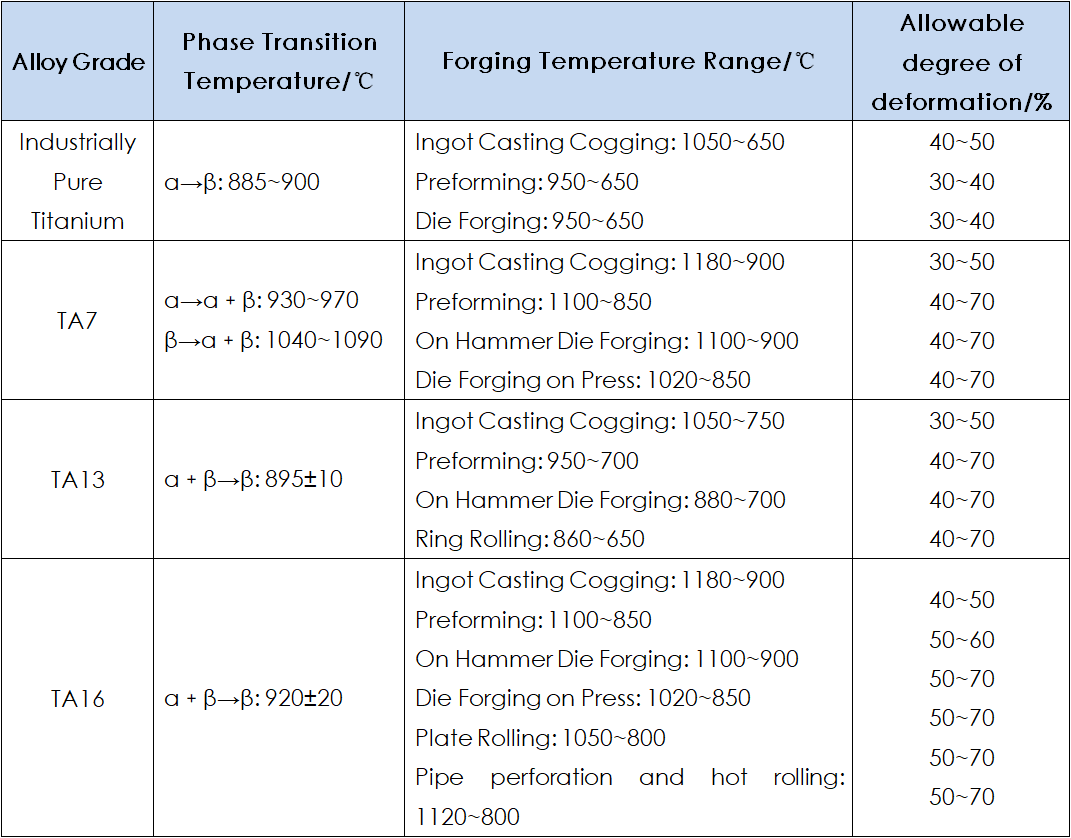

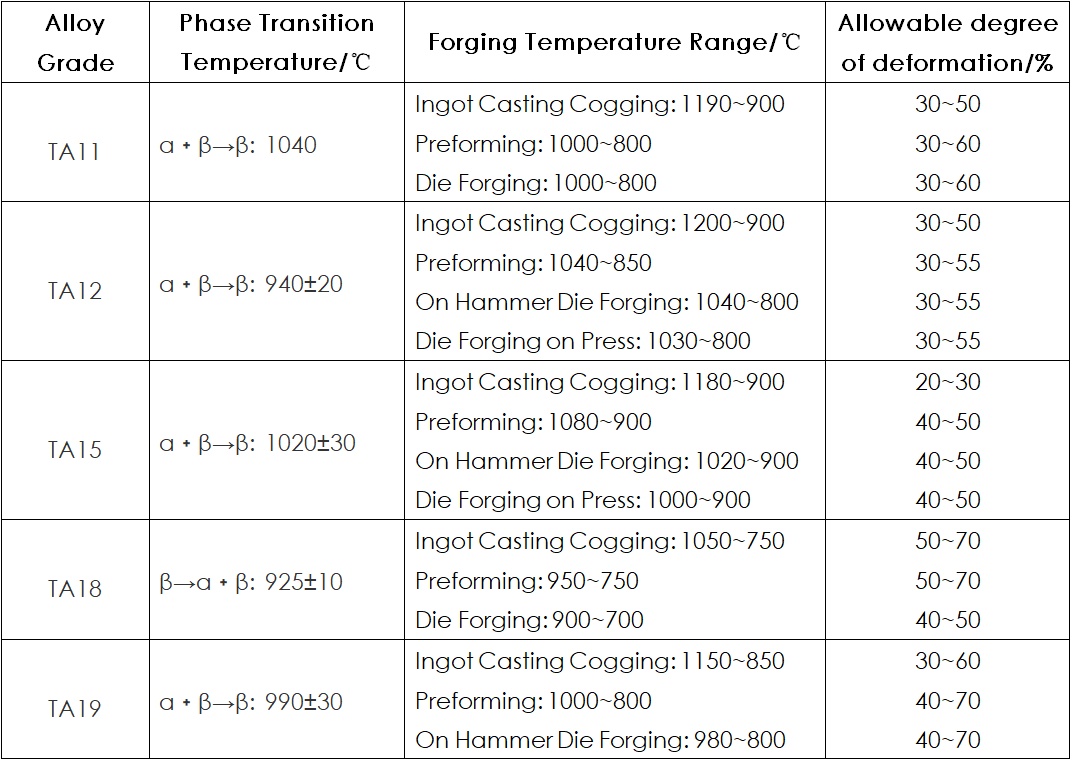

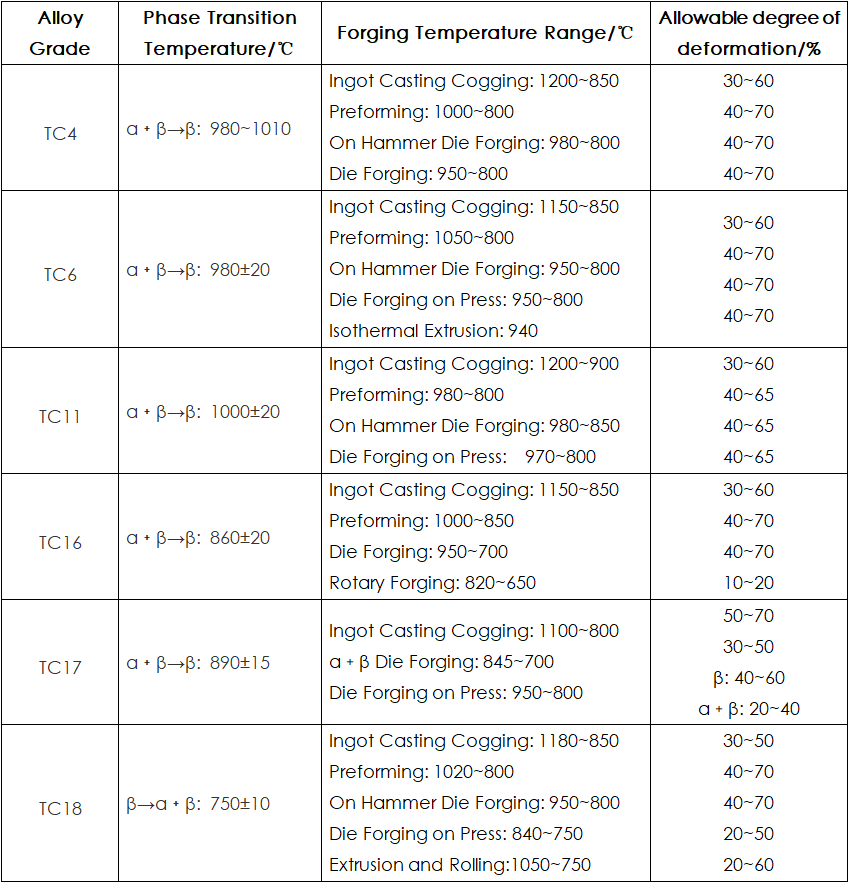

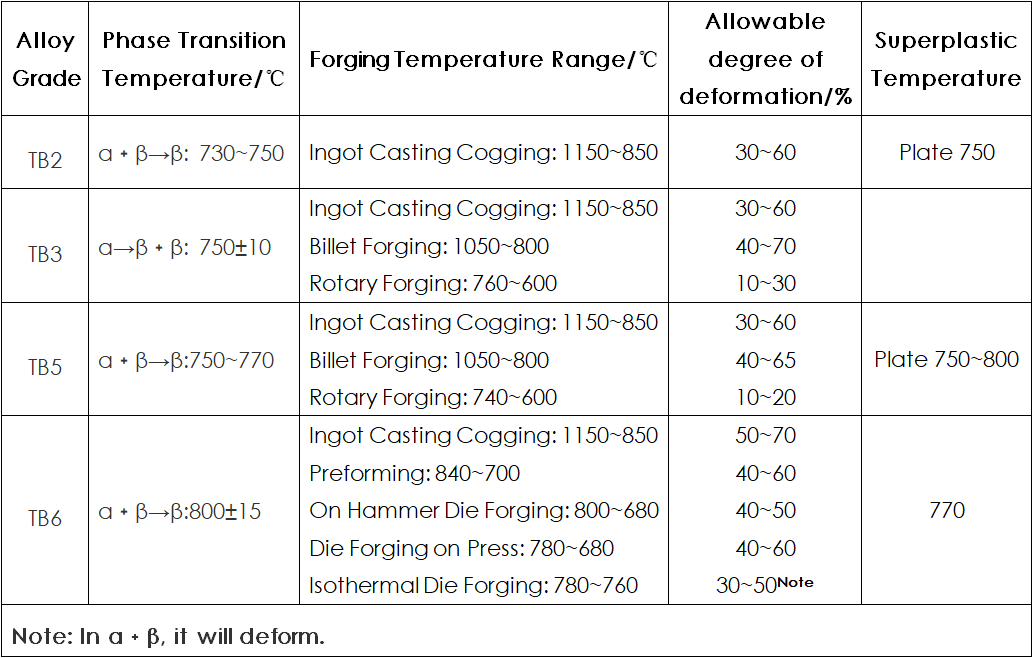

Dangane da bincike na ka'idar da ƙwarewar samarwa masana'anta, bayanan aikin ƙirƙira na nau'in α-nau'in, nau'in kusa-α-nau'in, nau'in α﹢β-nau'in da nau'in titanium gami da nau'in β-nau'in an taƙaita su a cikin Table 1 zuwa Table 4, bi da bi.

Daga bayanan da ke cikin Tebu 1 zuwa Tebu na 4, ana iya ganin cewa zazzabin lissafin mafi yawan ingots na titanium yana cikin kewayon 1150 ° C zuwa 1200 ° C, kuma farkon ƙirƙira na wasu ingots na titanium yana cikin kewayon. daga 1050 ° C zuwa 1100 ° C; Waɗannan yankuna biyu na zafin jiki duka suna cikin yankin lokaci na β, kuma na farko ya fi yanayin canjin lokaci saboda dalilai da yawa.

Na farko, gami yana da babban siffa da ƙarancin juriya a cikin yankin lokaci na β. Don yin ƙoƙari na dogon lokaci na ƙirƙira, yana da fa'ida don haɓaka yawan aiki; na biyu, billet na ingot blooming ana ba da shi a matsayin fanko don ƙirƙira. Bayan ƙirƙira tare da babban digiri na nakasawa, ana iya inganta tsarin ba tare da shafar aikin ƙirƙira ba. Sabili da haka, an zaɓi tsari tare da babban yawan aiki.

Daga bayanan da ke cikin Tebu 1 zuwa Tebu 4, ana iya ganin cewa farkon ƙirƙira zafin ƙirƙira na mutuƙar ƙirƙira akan latsa ba wai kawai ya yi ƙasa da yanayin ƙirƙira na farko na billet ɗin ingot ba, amma kuma ƙasa da yanayin canjin lokaci na α/β. da 30 ℃ ~ 50 ℃. Yawancin titanium The mutu ƙirƙira zafin jiki na gami ne a cikin kewayon 930 ℃ ~ 970 ℃, wanda shine don tabbatar da nakasawa a cikin α﹢β lokaci yankin don samun da ake bukata microstructure da kaddarorin na ƙirƙira. Tun da ƙirƙira guduma mutu ƙirƙira na bukatar mahara naushi da kuma aiki lokaci ne mai tsawo, da mutu forging dumama zafin jiki na gama forgings za a iya daidai ƙara da 10 ℃ ~ 20 ℃ fiye da na latsa ƙirƙira. Koyaya, don tabbatar da tsari da kaddarorin inji na titanium gami da gama ƙirƙira, Saboda haka, zafin ƙirƙira na ƙarshe na ƙirar ƙirƙira ya kamata a sarrafa shi a cikin yankin α﹢β biyu-lokaci.

Hakanan ana iya gani daga bayanan da ke cikin Tebura 1 zuwa Tebura 4 cewa zafin ƙirƙira na farko na mafi yawan abubuwan da aka tsara na titanium alloy ya ɗan fi girma ko kusa da yanayin canjin lokaci. Farkon zafin α/β mai ƙirƙira na tsarin canji kamar preforming yayi ƙasa da yanayin zafin fure, kuma sama da zafin ƙirƙira na farko na mutuwa ƙirƙira. Lalacewa a cikin wannan yankin zafin jiki ba kawai yana kula da yawan aiki ba, amma kuma yana shirya kyakkyawan tsari don ƙirƙira.

Table 1 Ƙirƙirar bayanan aikin aikin α-type titanium

Tebura 2 Ƙirƙirar bayanan aikin aiki na kusa da nau'in titanium gami da nau'in α

Table 3 Ƙirƙirar bayanan aikin aikin α﹢β titanium

Tebura 4 Ƙirƙirar bayanan aikin aiki na kusa da nau'in β titanium gami

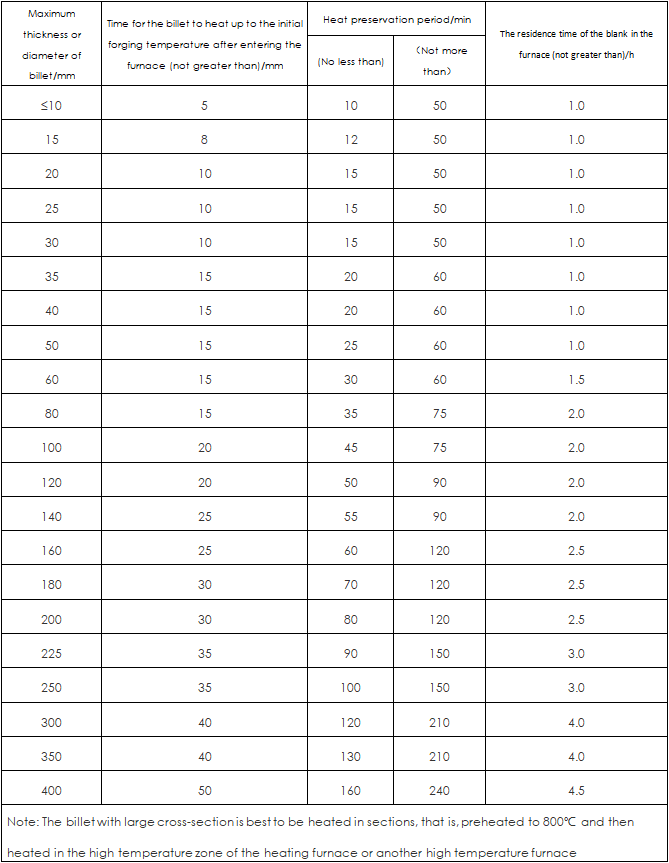

Tebura 5 Dumama da riƙe lokacin titanium gami blanks

BMT an ƙera shi a cikin samar da ƙirƙirar ƙirƙira ta titanium mai ƙirƙira da ƙirƙirar ƙirar titanium wanda ke nuna kyakkyawan ƙarfin injin, ƙarfin hali, juriya na lalata, ƙarancin ƙima da babban ƙarfi. BMT titanium kayayyakin 'daidaitaccen samarwa da tsarin ganowa sun shawo kan rikice-rikicen fasaha da wahalar injin ƙirƙira na masana'antar titanium.

The high quality madaidaicin titanium ƙirƙira samar dogara ne a kan fitar da ƙwararrun tsari zane da kuma a hankali ci gaba hanya. BMT titanium ƙirƙira za a iya amfani da kewayo daga kananan kwarangwal goyon bayan tsarin zuwa babban size titanium ƙirƙira na jiragen sama.

BMT titanium forgings ana amfani da ko'ina a yawancin masana'antu, kamar sararin samaniya, aikin injiniya na teku, mai da gas, wasanni, abinci, mota, da dai sauransu. Ƙarfin samar da mu na shekara-shekara ya kai ton 10,000.

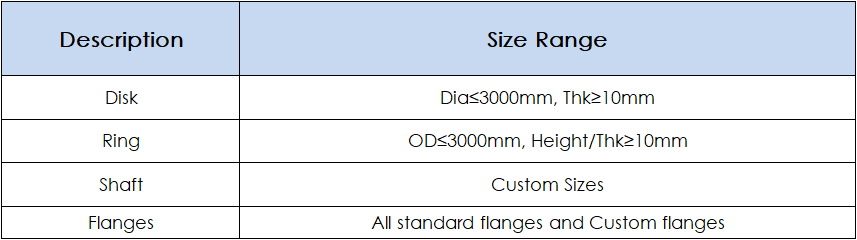

Tsawon girman:

Samfuran Haɗin Sinadarin Kayan Abu

Samfuran Haɗin Sinadarin Kayan Abu

Gwajin dubawa:

- Binciken Haɗin Sinadari

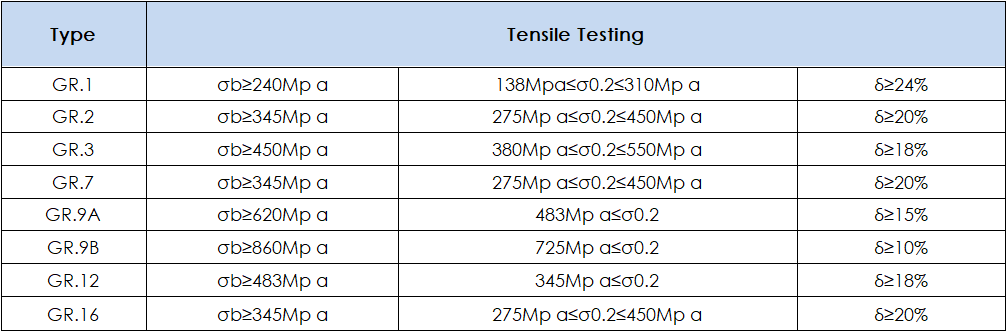

- Gwajin Kayayyakin Injini

- Gwajin tensile

- Gwajin Flaring

- Gwajin Lalacewa

- Lankwasawa Gwajin

- Gwajin Hydro-Static

- Gwajin huhu (Gwajin hawan iska a ƙarƙashin ruwa)

- Gwajin NDT

- Gwajin Eddy-Yanzu

- Gwajin Ultrasonic

- Gwajin LDP

- Gwajin Ferroxyl

Yawan aiki (Max da Min adadin oda):Unlimited, bisa ga tsari.

Lokacin Jagora:Gaba ɗaya lokacin jagoran shine kwanaki 30. Duk da haka, ya dogara da adadin odar bisa yarda.

Sufuri:Babban hanyar sufuri ita ce ta Teku, ta Air, ta Express, ta Train, wanda abokan ciniki za su zaɓa.

Shiryawa:

- Ƙarshen bututu don a kiyaye shi da filaye ko kwali.

- Duk kayan aikin da za'a shirya don kare iyaka da fuskantar.

- Duk sauran kayayyaki za a cika su ta hanyar kumfa mai kumfa da marufi masu alaƙa da filastik da lamunin plywood.

- Duk wani itace da aka yi amfani da shi don tattarawa dole ne ya dace don hana gurɓatawa ta hanyar tuntuɓar kayan aiki.