Ƙwarewar Zaɓin Kayan Aikin CNC Machining

Zaɓi Kayan aikin don CNC Milling

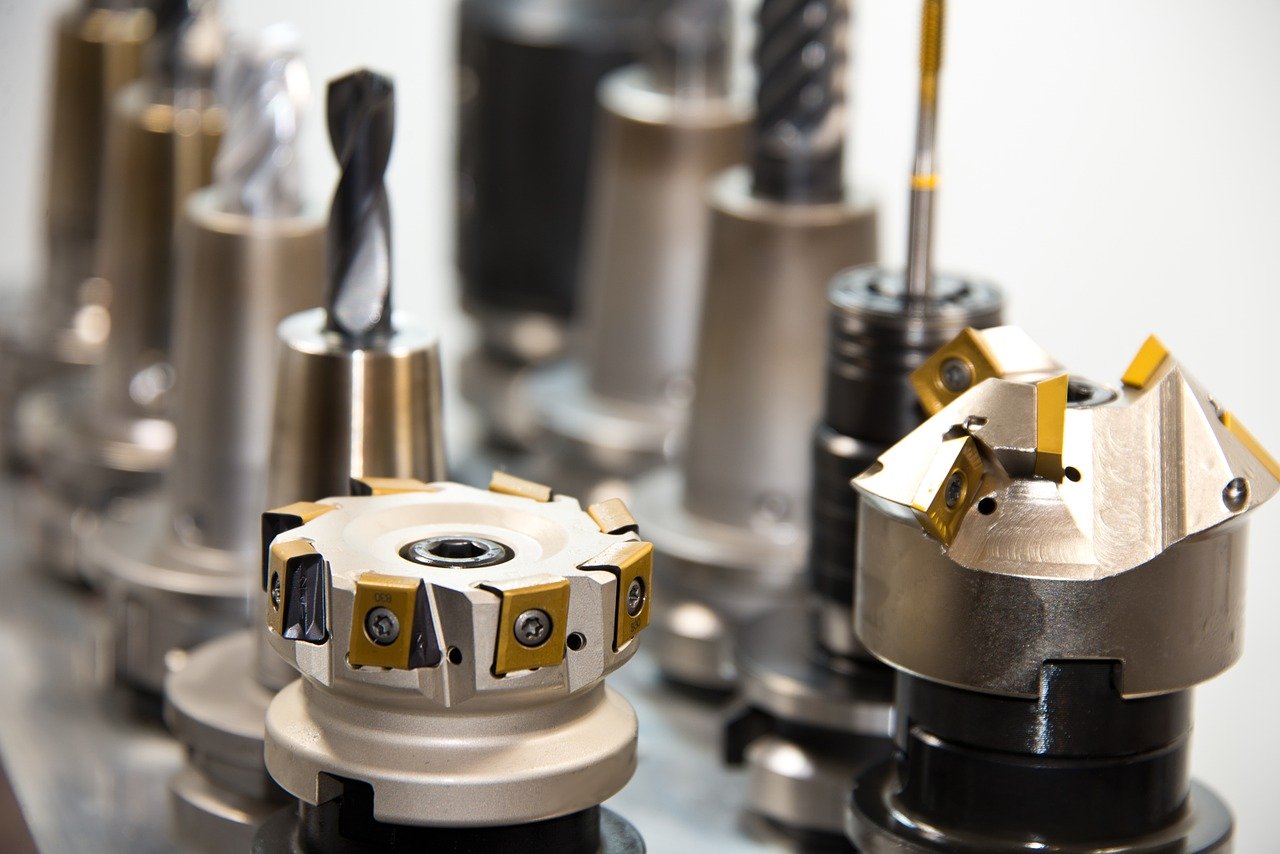

A cikin injinan CNC, ana amfani da injina na ƙarshe na lebur don niƙa ciki da waje na sassan jirgin sama da kuma jirgin niƙa. Bayanan da suka dace na sigogi masu dacewa na kayan aiki sune kamar haka: Na farko, radius na mai yankan milling ya kamata ya zama ƙasa da ƙananan radius na curvature Rmin na gefen kwane-kwane na ɓangaren, gabaɗaya RD = (0.8-0.9) Rmin . Na biyu shine tsayin aiki na sashin H< (1/4-1/6) RD don tabbatar da cewa wuka tana da isasshen ƙarfi. Na uku, lokacin da ake niƙa kasan tsagi na ciki tare da maƙalar ƙarshen ƙasa mai lebur, saboda wucewa biyu na kasan tsagi yana buƙatar haɗuwa, kuma radius na gefen ƙasa na kayan aiki shine Re = Rr, wato, diamita shine d=2Re=2(Rr), lokacin da ake shirin Ɗauki radius na kayan aiki azaman Re=0.95 (Rr).

Don sarrafa wasu bayanan martaba masu girma uku da kwane-kwane tare da kusurwoyi masu canzawa, masu yankan niƙa mai sassauƙa, masu yankan zobe, masu yankan ganga, masu yankan niƙa da masu yankan diski galibi ana amfani da su. A halin yanzu, yawancin kayan aikin injin na CNC suna amfani da siriyal da daidaitattun kayan aikin. Akwai ma'auni na ƙasa da ƙirar ƙira don masu riƙe kayan aiki da shugabannin kayan aiki kamar kayan aikin jujjuyawar waje mai ƙididdigewa da kayan aikin jujjuyawar fuska. Don cibiyoyin injuna da masu canza kayan aiki na atomatik Kayan aikin injin da aka shigar da masu riƙe kayan aiki an daidaita su kuma an daidaita su. Misali, daidaitaccen lambar tsarin kayan aikin shank ɗin da aka ɗora shine TSG-JT, kuma madaidaicin lambar madaidaicin tsarin kayan aikin shank shine DSG-JZ. Bugu da ƙari, don kayan aikin da aka zaɓa Kafin amfani, ya zama dole don auna girman kayan aiki sosai don samun cikakkun bayanai, kuma ma'aikacin zai shigar da waɗannan bayanan a cikin tsarin bayanan, kuma ya kammala aikin sarrafawa ta hanyar kiran shirin, ta haka ne ke sarrafa ƙwararrun workpieces. .

Wurin Lantarki na Kayan aiki da Wurin Canjin Kayan aiki

Daga wane matsayi kayan aiki ya fara motsawa zuwa matsayi da aka ƙayyade? Don haka a farkon aiwatar da shirin, dole ne a ƙayyade matsayin da kayan aiki ya fara motsawa a cikin tsarin daidaitawa na workpiece. Wannan matsayi shine farkon kayan aiki dangane da kayan aiki lokacin da aka aiwatar da shirin. Don haka ana kiran shi wurin farawa ko farawa. Gabaɗaya ana ƙayyade wannan wurin farawa ta hanyar saitin kayan aiki, don haka ana kiran wannan wurin saitin kayan aiki. Lokacin tattara shirin, dole ne a zaɓi matsayin wurin saitin kayan aiki daidai. Ka'idar saitin saitin kayan aiki shine sauƙaƙe sarrafa lambobi da sauƙaƙe shirye-shirye.

Yana da sauƙi don daidaitawa da dubawa yayin aiki; Kuskuren sarrafawa da aka haifar yana da ƙananan. Za'a iya saita wurin saitin kayan aiki akan sashin da aka yi amfani da shi, akan kayan aiki ko akan kayan aikin injin. Domin inganta daidaiton injinan sashin, yakamata a saita wurin saitin kayan aiki gwargwadon yuwuwar akan ma'anar ƙira ko tushen tsari. A cikin ainihin aikin na'ura na kayan aiki, za a iya sanya madaidaicin matsayi na kayan aiki a kan kayan aiki na kayan aiki ta hanyar aiki na kayan aiki na kayan aiki, wato, daidaituwa na "matsayin matsayi na kayan aiki" da "maganin saitin kayan aiki". Abin da ake kira "ma'anar wuri na kayan aiki" yana nufin matsayi na datum point na kayan aiki, kuma wurin wurin kayan aiki na kayan aiki na kayan aiki shine kayan aiki na kayan aiki ko tsakiyar kayan aiki arc.

Mill mai lebur mai laushi shine ma'amala na kayan kayan aiki da kuma kasan kayan aiki; niƙa-karshen ball shine tsakiyar ƙwallon, kuma rawar jiki shine batu. Yin amfani da aikin saitin kayan aiki na hannu, daidaiton saitin kayan aikin yana da ƙasa, kuma ingancin yana da ƙasa. Wasu masana'antu suna amfani da madubin saitin kayan aikin gani, kayan saitin kayan aiki, na'urorin saitin kayan aiki na atomatik, da sauransu don rage lokacin saitin kayan aiki da haɓaka daidaiton saitin kayan aiki. Lokacin da ake buƙatar canza kayan aiki yayin aiki, ya kamata a ƙayyade wurin canjin kayan aiki. Abin da ake kira "ma'anar canjin kayan aiki" yana nufin matsayi na kayan aiki lokacin da yake juyawa don canza kayan aiki. Ya kamata wurin canza kayan aiki ya kasance a waje da kayan aiki ko kayan aiki, kuma kada a taɓa kayan aikin da sauran sassa yayin canjin kayan aiki.

Tushen wannan nau'in kayan aikin juyawa ya ƙunshi manyan gefuna na madaidaiciya da na biyu, kamar kayan aikin juyawa na ciki da na waje na 900, kayan aikin juyawa na hagu da dama na ƙarshen fuska, tsagi (yanke) kayan aikin juyawa, da daban-daban na waje da na ciki yankan gefuna tare da. kananan tip chamfers. Kayan aikin juyawa rami. Hanyar zaɓin ma'auni na juzu'i na kayan aikin jujjuyawa mai nuni (yafi kusurwar geometric) daidai yake da na jujjuyawar yau da kullun, amma halayen injinan CNC (kamar hanyar injin, tsangwama, da sauransu) yakamata a yi la'akari da su gaba ɗaya. , kuma tip kayan aiki kanta yakamata a yi la'akari da ƙarfi.

Ƙayyade Adadin Yanke

A cikin shirye-shiryen NC, mai shirye-shiryen dole ne ya ƙayyade adadin yanke kowane tsari kuma ya rubuta shi a cikin shirin ta hanyar umarni. Yanke sigogi sun haɗa da saurin igiya, adadin yankan baya da saurin ciyarwa. Don hanyoyin sarrafawa daban-daban, ana buƙatar zaɓar sigogi daban-daban. Ka'idar zaɓi na adadin yankan shine don tabbatar da daidaiton mashin ɗin da ƙarancin ƙasa na sassa, ba da cikakken wasa ga aikin yankan kayan aiki, tabbatar da dorewar kayan aiki mai ma'ana, da ba da cikakkiyar wasa ga aikin injin ɗin don haɓaka yawan aiki. da rage farashi.