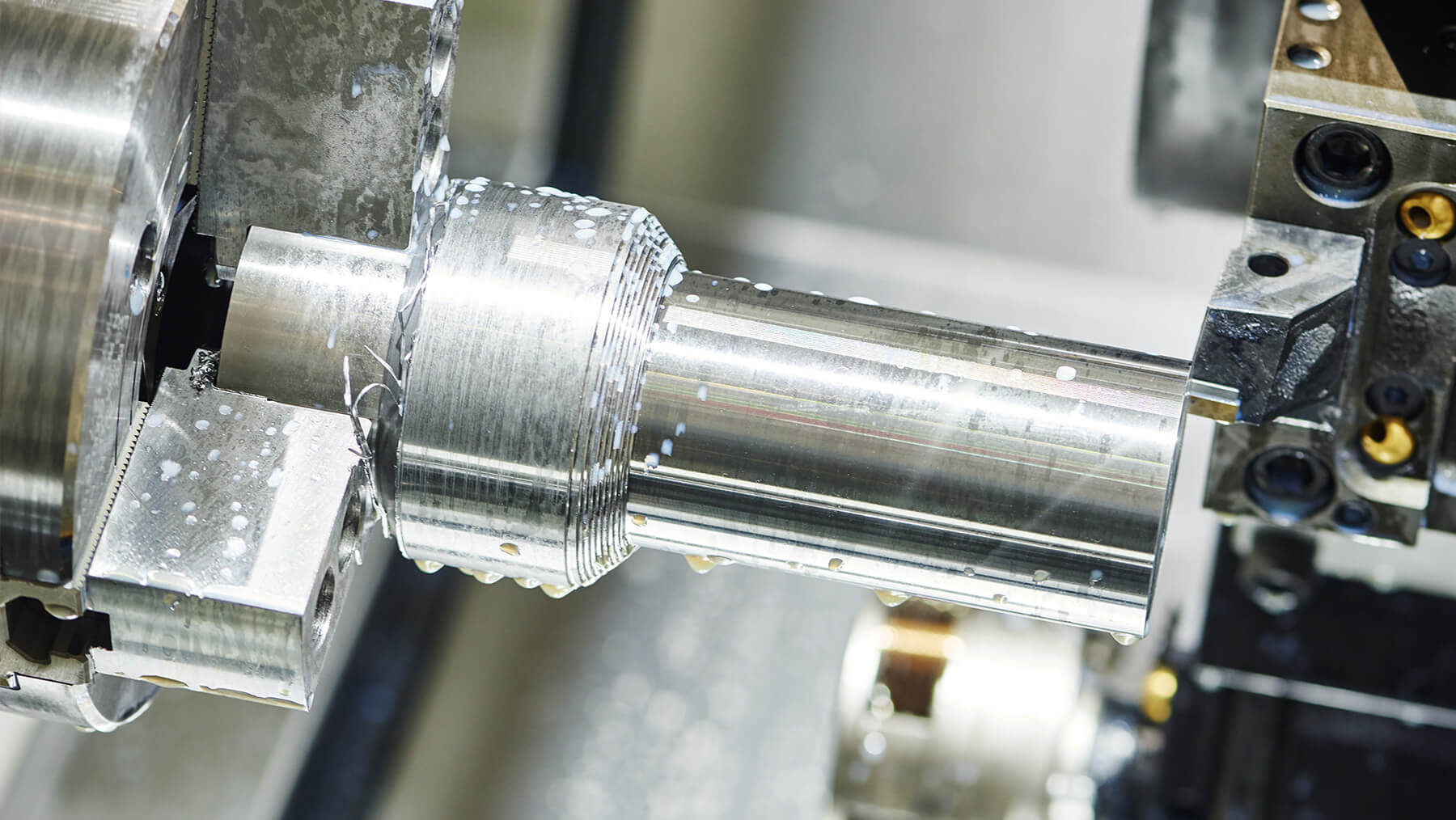

TheAerospace da kuma masana'antun likitasuna ci gaba da haɓakawa, kuma buƙatar kayan aiki masu inganci waɗanda zasu iya jure wa matsanancin yanayi yana kasancewa koyaushe. Ƙirƙirar titanium, daidai da ƙa'idodin ASTM B381, ya fito a matsayin muhimmin sashi don biyan waɗannan buƙatun. Tare da ƙaƙƙarfan ƙarfinsa, yanayin nauyi mai nauyi, da juriya na lalata, titanium ya zama kayan zaɓi don aikace-aikace da yawa, daga kayan aikin jirgin sama zuwa ƙwararrun likitanci. ASTM B381 shine daidaitaccen ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙirƙira na titanium da titanium gami da ƙirƙira, yana fayyace buƙatun don abun cikin sinadarai, kaddarorin injiniyoyi, da bambance-bambancen ma'auni.

Wannan ma'auni yana tabbatar da cewa ƙirƙirar titanium sun haɗu da ingantacciyar inganci da ƙa'idodin aiki waɗanda suka wajaba don amfani a aikace-aikace masu mahimmanci. A cikin masana'antar sararin samaniya, ƙirƙira titanium na taka muhimmiyar rawa wajen samar da kayan aikin jiragen sama. Daga abubuwan tsari zuwa sassan injin, titanium's high ƙarfi-to-nauyi rabo ya sa ya zama manufa abu don inganta aikin jirgin sama da kuma man fetur yadda ya dace. Bugu da ƙari, jurewarsa ga lalata da yanayin zafi mai zafi ya sa ya dace da aikace-aikacen sararin samaniya. Haka kuma, masana'antar likitanci ta kuma rungumi yin amfani da jabun titanium saboda dacewarsu da juriya ga ruwan jiki. Abubuwan da aka saka Titanium, irin su maye gurbin hip da gwiwa, kayan aikin haƙori, da na'urorin gyara kashin baya, sun ƙara yaɗuwa, suna ba marasa lafiya mafita mai ɗorewa kuma mai dorewa don yanayin kiwon lafiya daban-daban. Yin amfani da jabun titanium a cikin masana'antu biyu ya haifar da ci gaba a fasaha da ƙira.

Misali, haɓaka hadaddun abubuwa masu nauyi, an yi su ta hanyarmadaidaicin ƙirƙira na titanium, ba da izini don haɓaka haɓakar iska a cikin sararin samaniya da haɓaka aiki a cikin na'urorin likitanci. Bugu da ƙari, ɗaukar ka'idodin ASTM B381 yana tabbatar da cewa ƙirƙira titanium ya cika mafi girman inganci da buƙatun aminci. Wannan ƙayyadaddun ba wai kawai yana amfanar masana'antun ta hanyar samar da ƙayyadaddun ƙa'idodi don samarwa ba amma har ma yana sanya kwarin gwiwa ga masu amfani da ƙarshen dangane da aminci da aikin ƙirƙira na titanium. Yayin da buƙatun ƙirƙira na titanium ke ci gaba da girma, bincike da ƙoƙarin haɓaka suna mai da hankali kan ƙara haɓaka kaddarorin kayan da faɗaɗa aikace-aikacen sa. Ci gaba da ci gaba a cikin fasahohin ƙirƙira da abubuwan haɗin gwal suna nufin tura iyakokin abin da titanium zai iya cimma, buɗe sabbin damar yin amfani da shi a masana'antu daban-daban.

Baya ga kayan aikin injiniyansa, dorewar ƙirƙirar titanium shima wani muhimmin al'amari ne a cikin karɓuwarsa da yawa. Titanium yana da cikakken sake yin amfani da shi, kuma tsarin ƙirƙira da kansa yana da ƙarfi mai ƙarfi, yana mai da shi zaɓi mai dacewa da muhalli ga masana'antun da masu amfani gaba ɗaya. Ana sa ran gaba, makomar ƙirƙira titanium daidai da ka'idodin ASTM B381 ya bayyana mai ban sha'awa. Kamar yadda ci gaban fasaha ke haifar da haɓakar sararin samaniya da fasahar likitanci, ƙirƙira titanium za ta ci gaba da kasancewa a sahun gaba wajen ƙirƙira, da ba da damar haɓaka samfuran aminci, inganci, da dorewa.

A ƙarshe, titanium ƙirƙira a yarda daASTM B381 Matsayiya zama wani abu mai mahimmanci ga sararin samaniya da masana'antun likitanci. Kaddarorin sa na musamman, haɗe tare da tabbataccen ingancin da aka bayar ta ma'aunin ASTM, sun sanya ginshiƙi na titanium a matsayin ginshiƙin ci gaban fasaha. Tare da ci gaba da bincike da ci gaba, yuwuwar ci gaba da haɓakawa da haɓaka aikace-aikace don ƙirƙira titanium yana da yawa, yana ba da alƙawarin nan gaba inda wannan abu mai ban mamaki ya ci gaba da siffanta sahun gaba na sararin samaniya da fasahar likitanci.

Lokacin aikawa: Afrilu-07-2024