Yanayin bugun bugun jini da Ci gaba da Wave

Wani muhimmin ɓangare na micromachining na gani shine canja wurin zafi zuwa yankin da ke kusa da ƙananan kayan aiki. Lasers na iya aiki a cikin yanayin bugun jini ko ci gaba da yanayin igiyar ruwa. A ci gaba da yanayin igiyar ruwa, fitarwar Laser yana dawwama sosai akan lokaci.

A cikin yanayin pulsed, fitarwar laser yana mai da hankali a cikin ƙananan bugun jini. Na'urorin Laser na yanayin ƙwanƙwasa suna ba da bugun jini da ƙananan lokutan bugun jini tare da isassun kuzari don micromachining na wani abu da aka bayar. Karamin lokacin bugun bugun jini yana rage zafin zafi zuwa kayan da ke kewaye. Laser bugun jini na iya bambanta da tsayi daga millise seconds zuwa femtoseconds.

Ƙarfin kololuwar yana da alaƙa da tsawon lokacin bugun jini na Laser, don haka na'urar bugun jini na iya cimma kololuwa mafi girma fiye da ci gaba da taguwar ruwa.

Sarrafa Laser da farko ya ƙunshi hulɗar da ke haifar da zubar da abin da ke cikin ƙasa. Canjin makamashin da ke faruwa ya dogara da kayan abu da kayan laser. Halayen Laser waɗanda ke tasiri abubuwan sun haɗa da ƙarfin kololuwa, faɗin bugun bugun jini, da tsayin iska. Wani abin la'akari shine ko zai iya sha makamashin Laser ta hanyar thermal da/ko tsarin photochemical.

Me yasa fadin bugun bugun jini yake da mahimmanci?

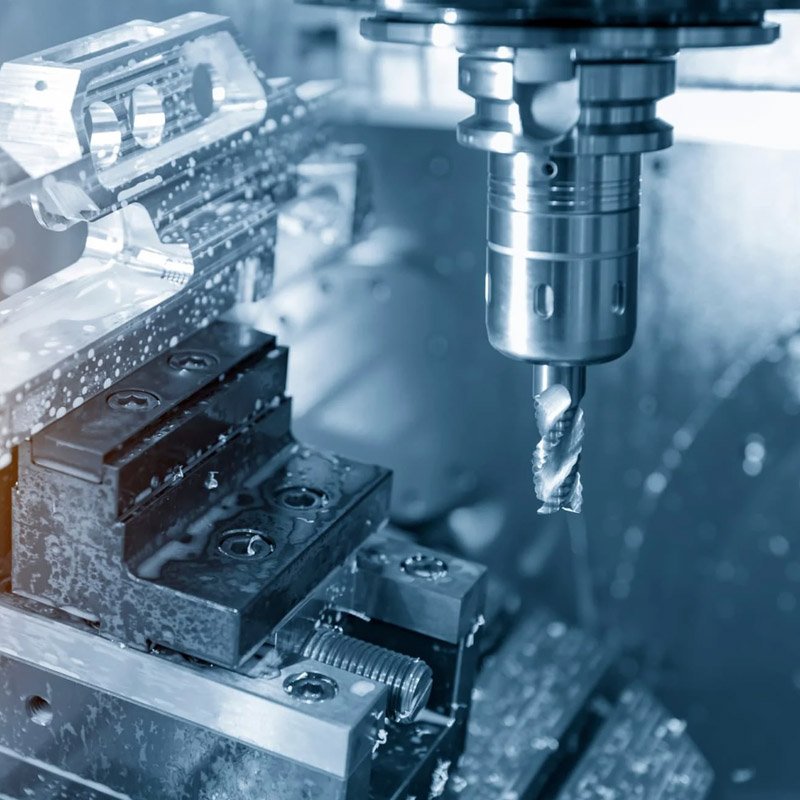

Yanke Laser tsafta ne kuma daidai. Bukatar yin ƙarami, sauri, na'urori masu sauƙi da ƙananan farashi yana buƙatar laser don saduwa da kalubale. Ana amfani da laser pulsed don daidaitaccen micromachining na kayan daban-daban. Ƙarfin samar da nau'i-nau'i daban-daban na bugun jini shine mabuɗin zuwa daidaito, kayan aiki, inganci da ƙimar farashi.

Nanosecond lasers suna amfani da matsakaicin matsakaicin ƙarfi tare da ƙimar cire kayan abu mafi girma kuma saboda haka mafi girman kayan aiki fiye da picosecond da laser na femtosecond.

Picosecond da femtosecond Laser narke kayan don cire shi ta hanyar yin tururi da narkewar kayan don fitar da shi. Wannan narkewa zai iya rinjayar daidaito da ingancin machining, kamar yadda kayan da aka cire zai iya jingina ga gefuna kuma ya sake gyarawa.

Ci gaban fasahar Laser mai bugun jini ya ba da damar yin amfani da micromachining akan ƙananan na'urori, kamar na'urorin likitanci, tare da ƙarancin lalacewa ga kayan da ke kewaye. Tare da saurin ci gaban kimiyya a fagen laser, ƙwarewar micromachining laser yana da mahimmanci.

Tsarin samar da injin yana nufin gabaɗayan tsarin yin samfuri daga albarkatun ƙasa (ko samfuran da aka kammala). Don samar da na'ura, ya haɗa da sufuri da adana kayan albarkatun kasa, shirye-shiryen samarwa, masana'anta mara kyau, sarrafa sassa da maganin zafi, haɗuwa da samfur, da lalata, zane-zane da marufi, da dai sauransu Abubuwan da ke cikin tsarin samarwa yana da yawa sosai. Kamfanoni na zamani suna amfani da ka'idoji da hanyoyin injiniyan tsarin don tsarawa da jagoranci samarwa, kuma suna ɗaukar tsarin samarwa azaman tsarin samarwa tare da shigarwa da fitarwa.

Lokacin aikawa: Oktoba-13-2022