Madaidaicin Sabis ɗin Injin mu na CNC

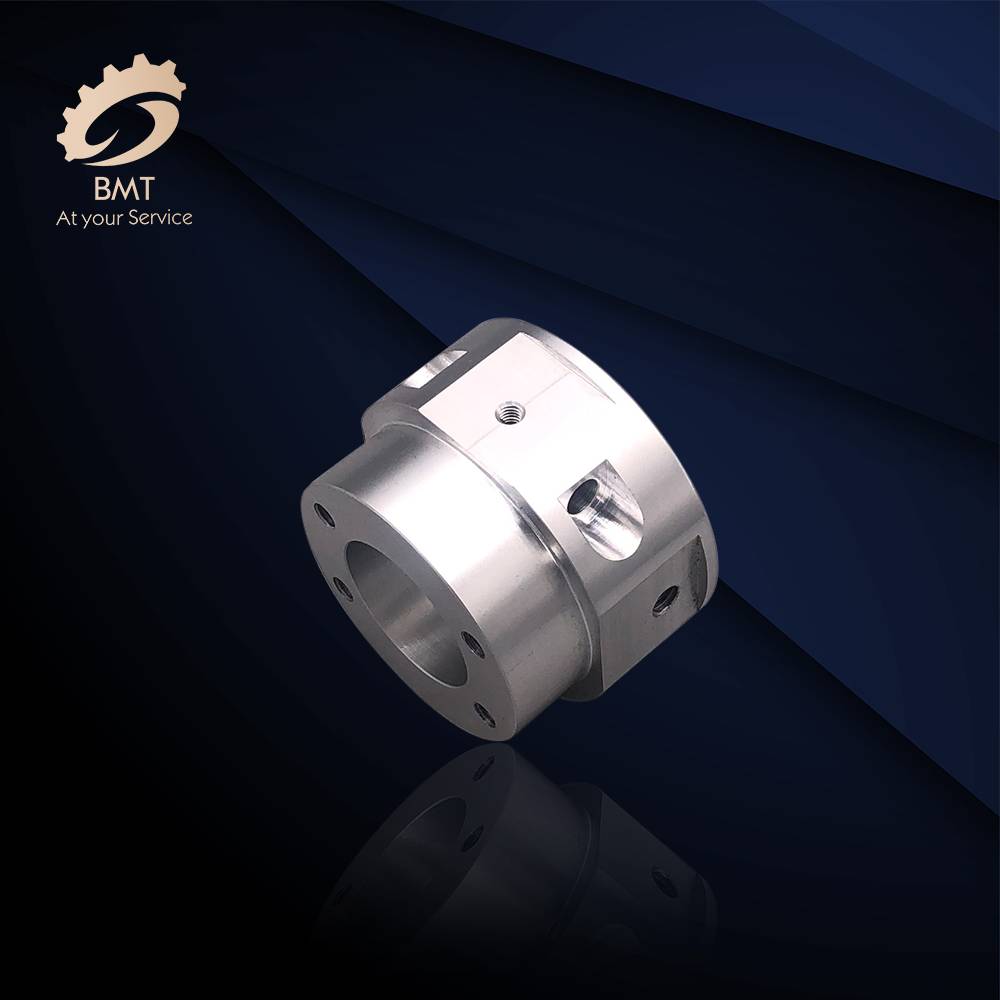

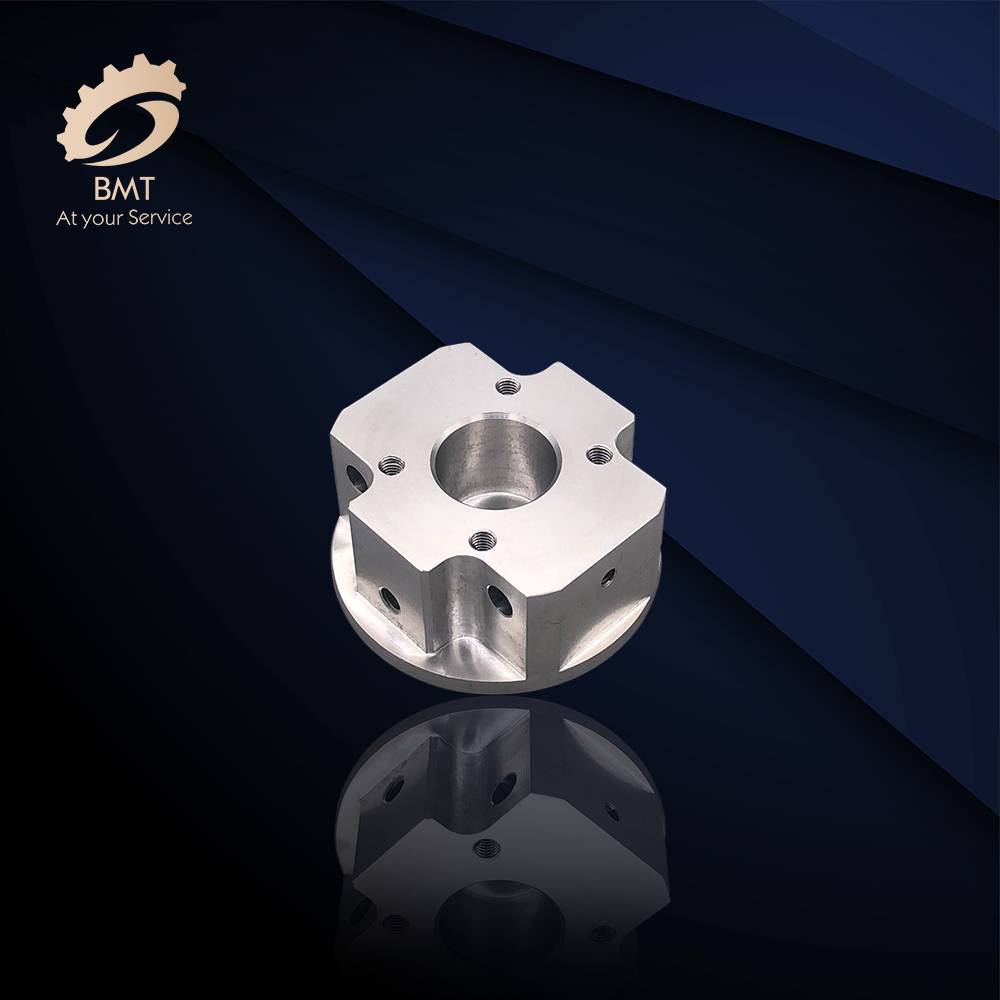

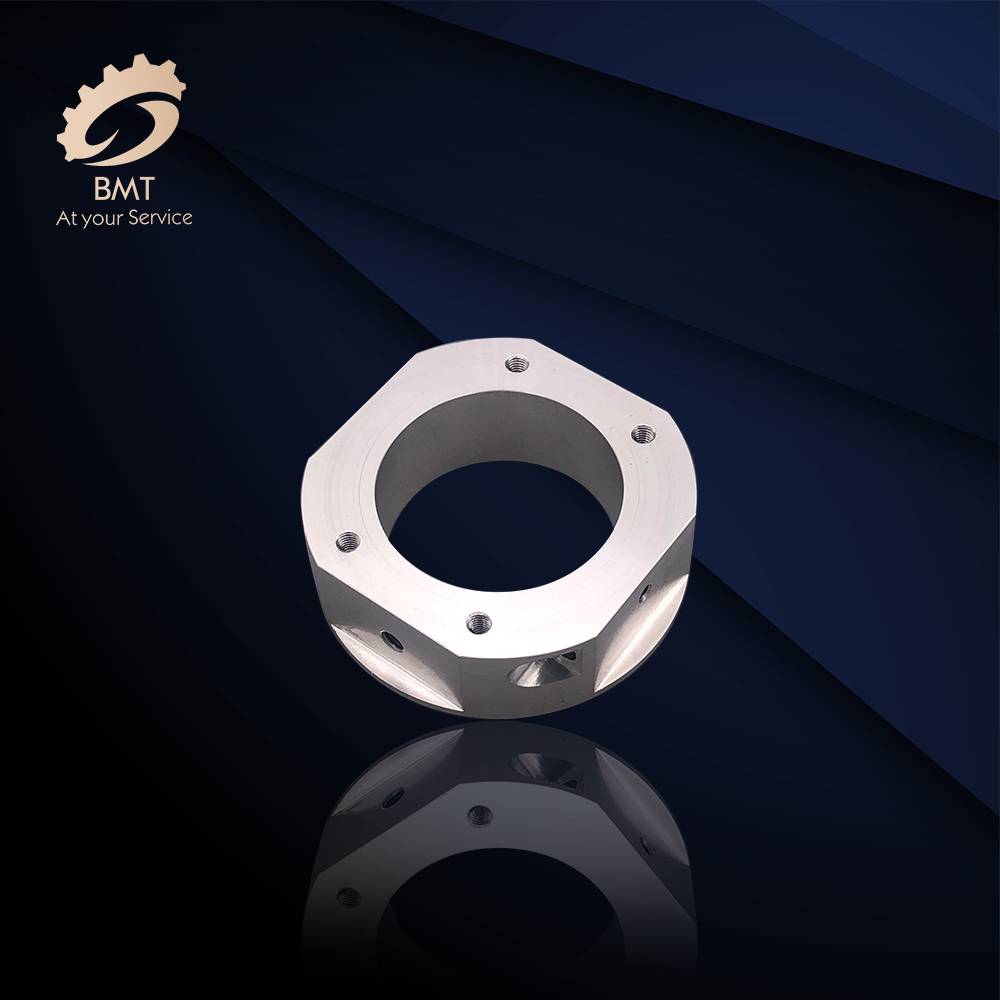

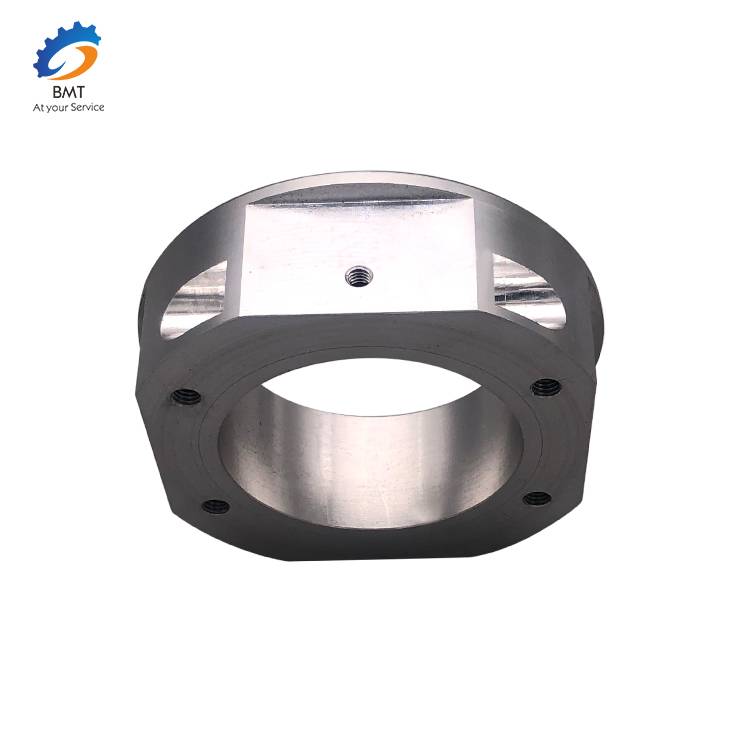

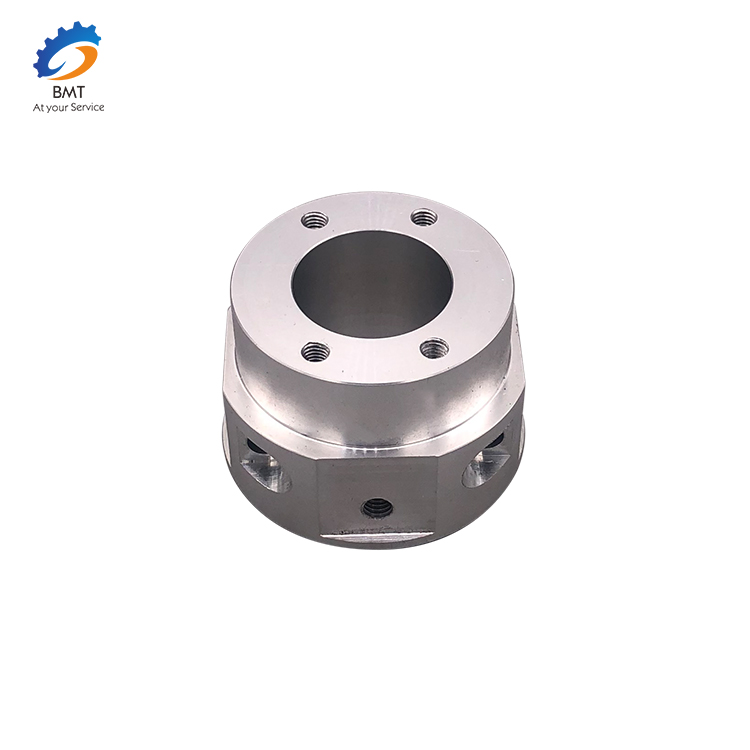

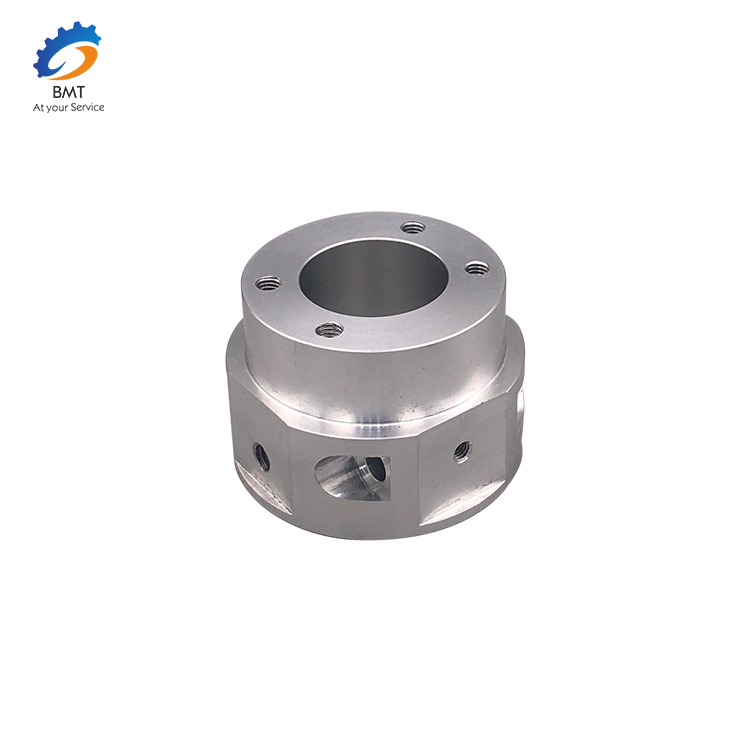

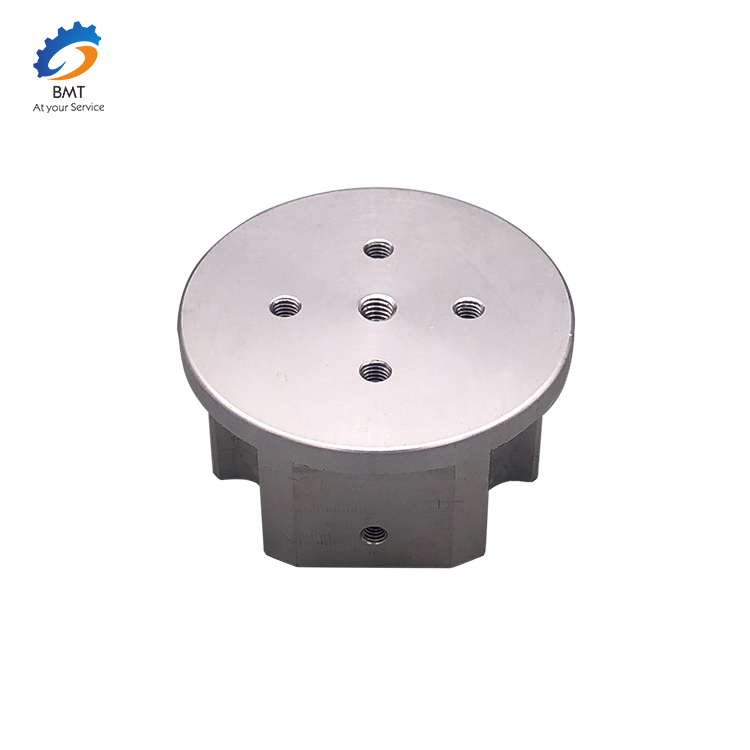

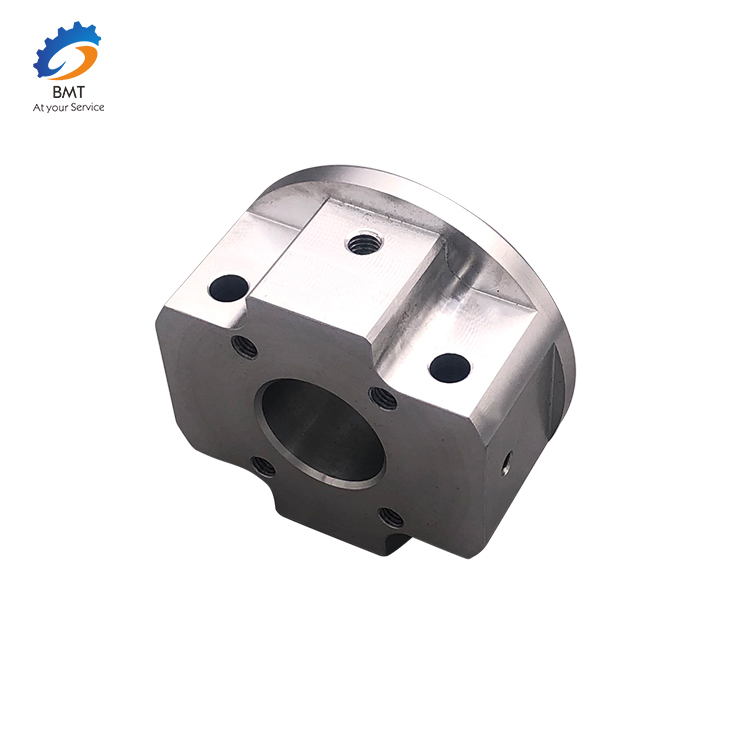

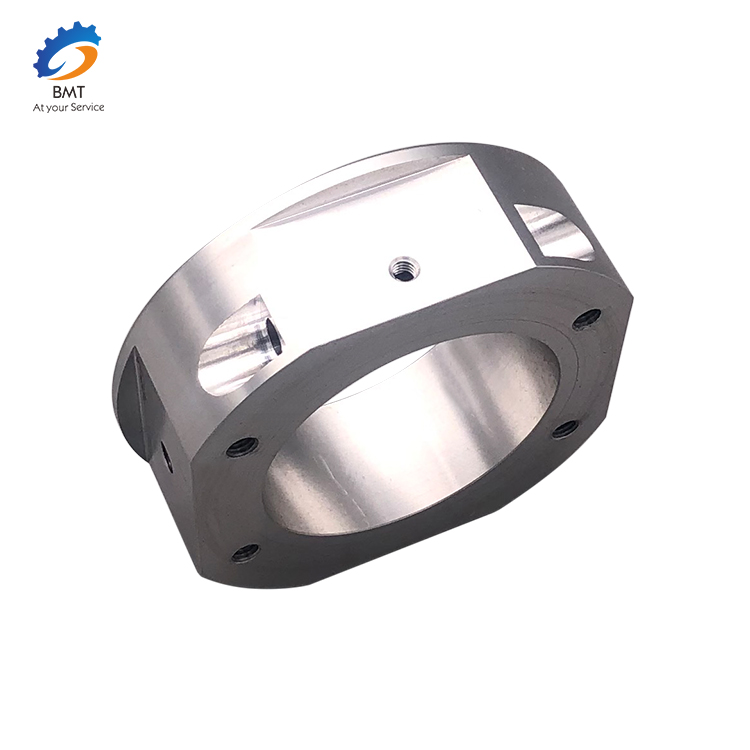

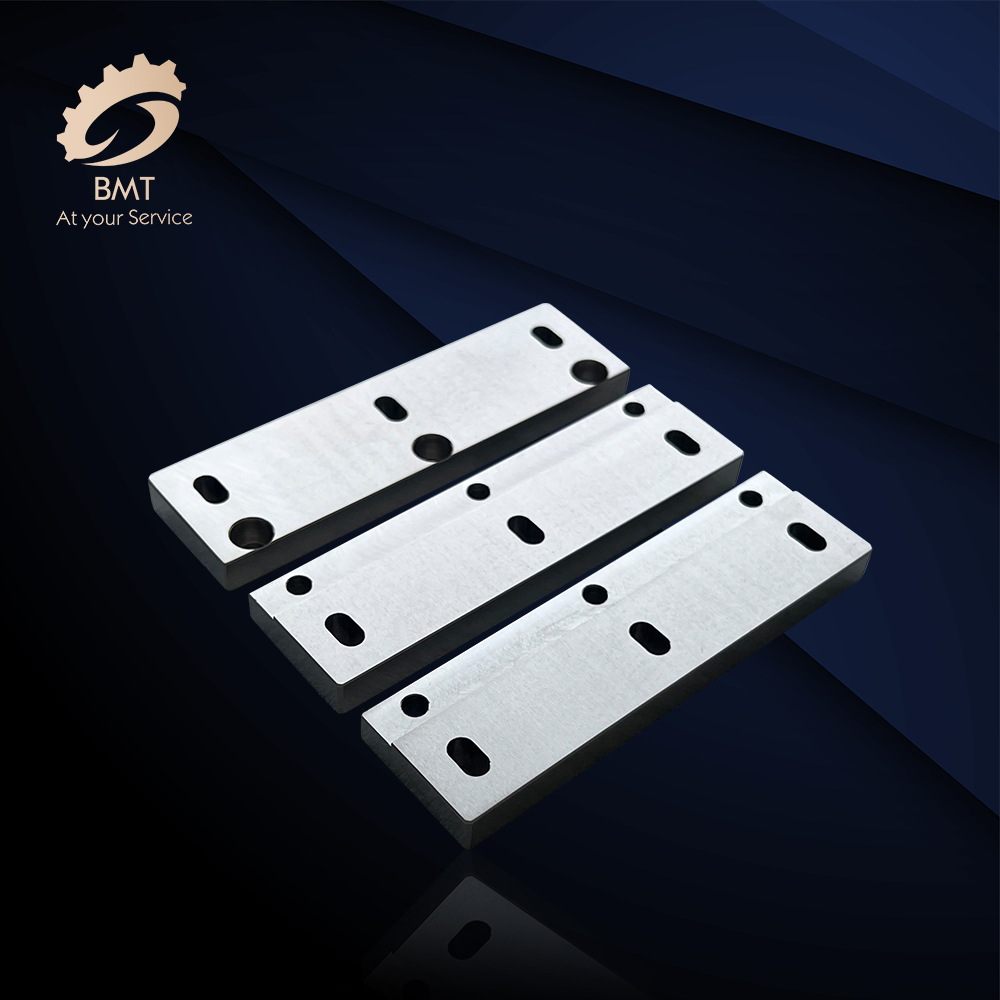

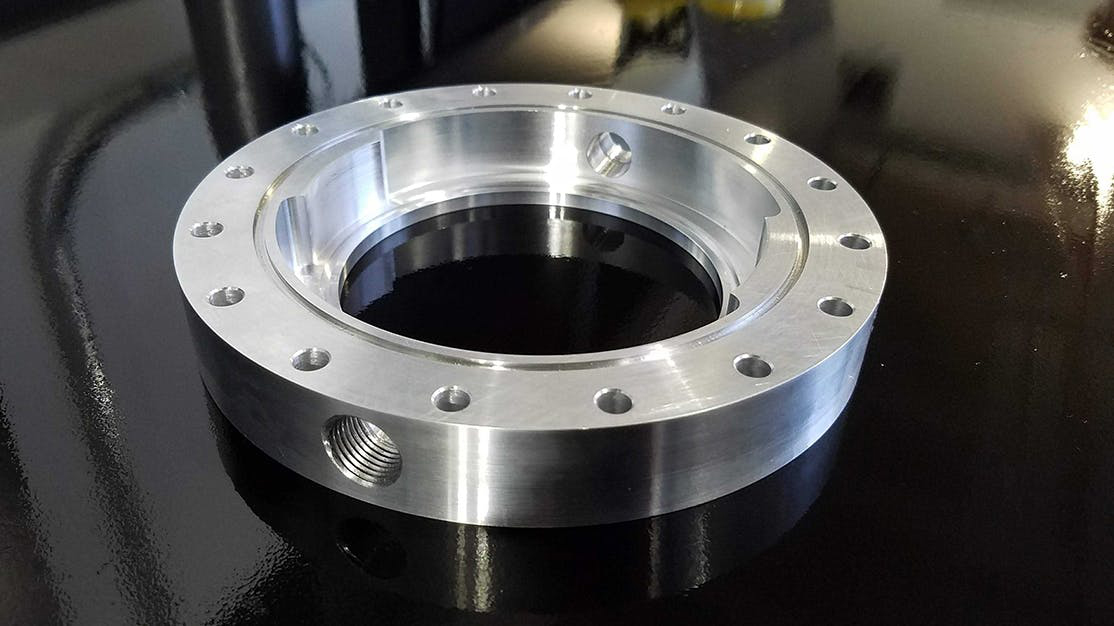

Ana amfani da mashin daidaici sau da yawa don sassan da ke buƙatar kusanci.Injiniyan ƙwararru na iya kera hadaddun sassa tare da ƙayyadaddun ƙayyadaddun bayanai, ta amfani da injin sarrafa CNC ko ƙwararren lathe.Yawancin injina a yau an kammala su da injinan CNC da software na AutoCAD, kuma suna iya amfani da shirye-shiryen CAM.Yawancin ƙira sun dogara da shirye-shiryen CAD/CAM.

Hakanan yana aiki akan nau'ikan karafa iri-iri ciki har da bakin / carbon karfe, aluminum, da tagulla da sauran kayan kamar robobi.Dangane da albarkatun kasa, ana iya amfani da injuna daban-daban.Injiniyan na iya buƙatar yin amfani da lathes, injin matsi, injinan niƙa, da injiniyoyi masu sauri don cire abu daga kayan aikin.

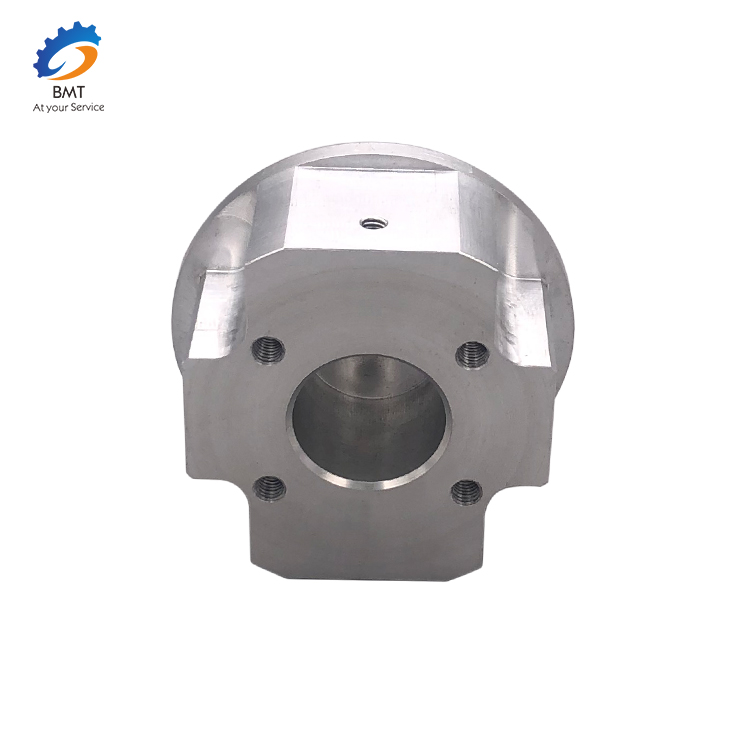

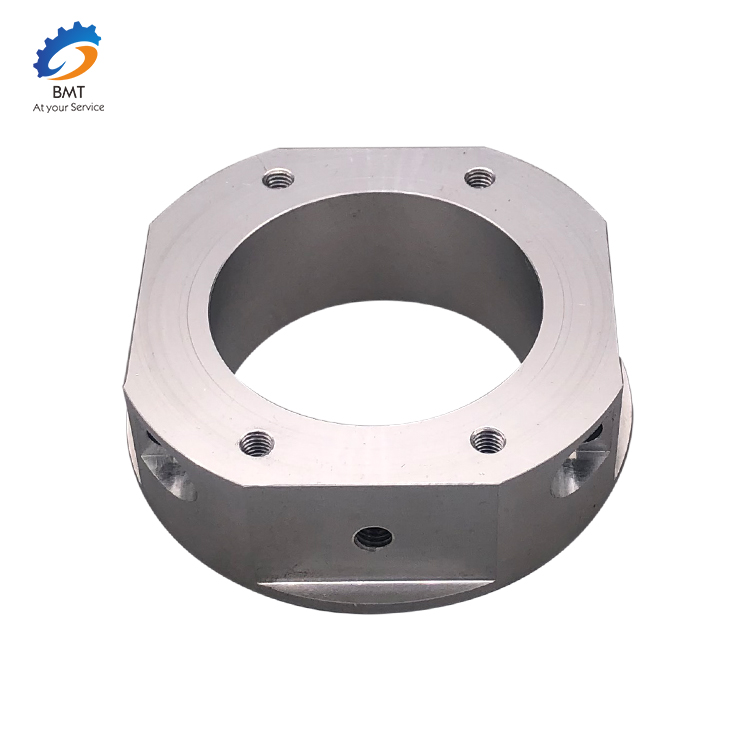

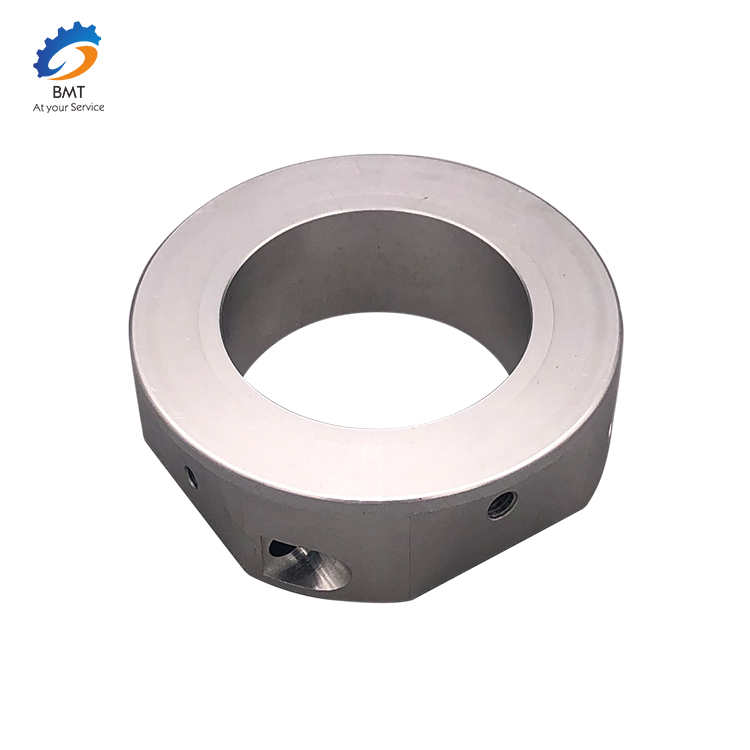

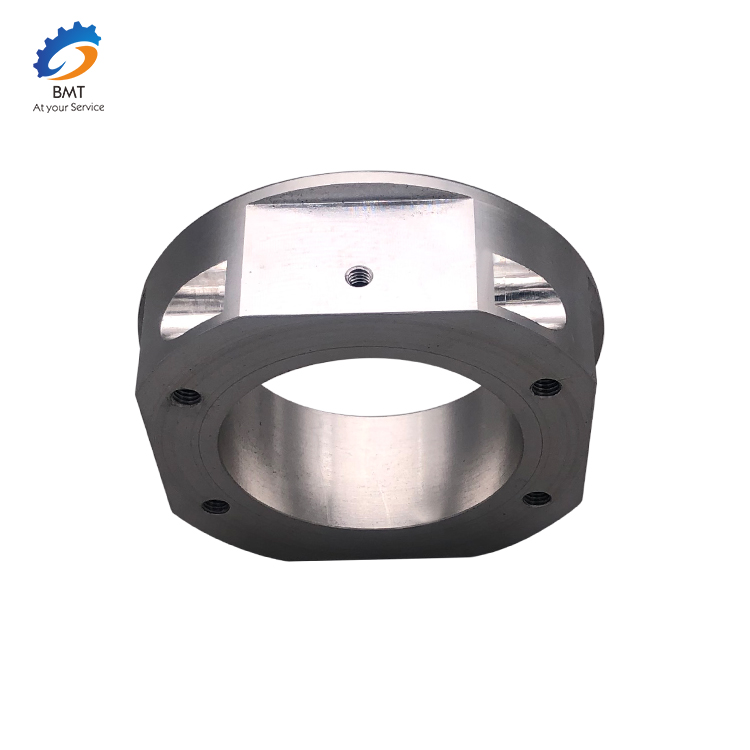

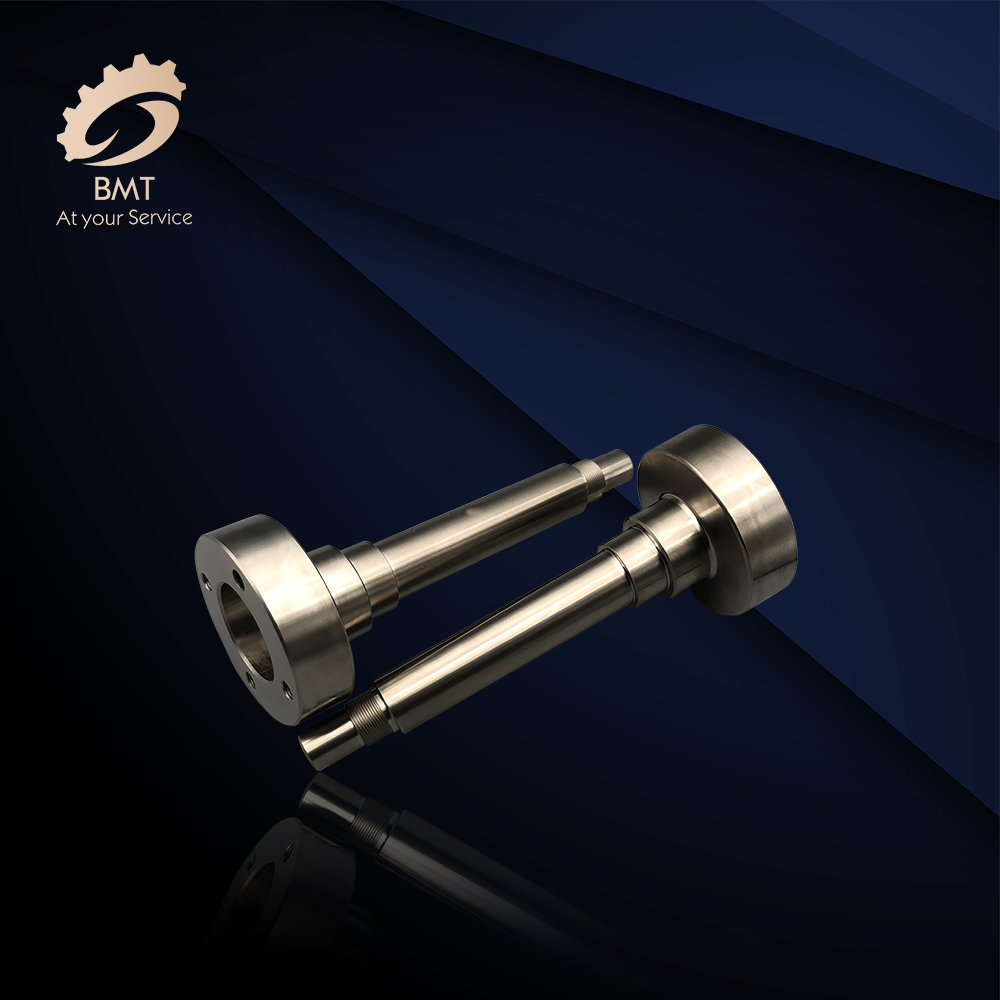

Bayanin Samfura

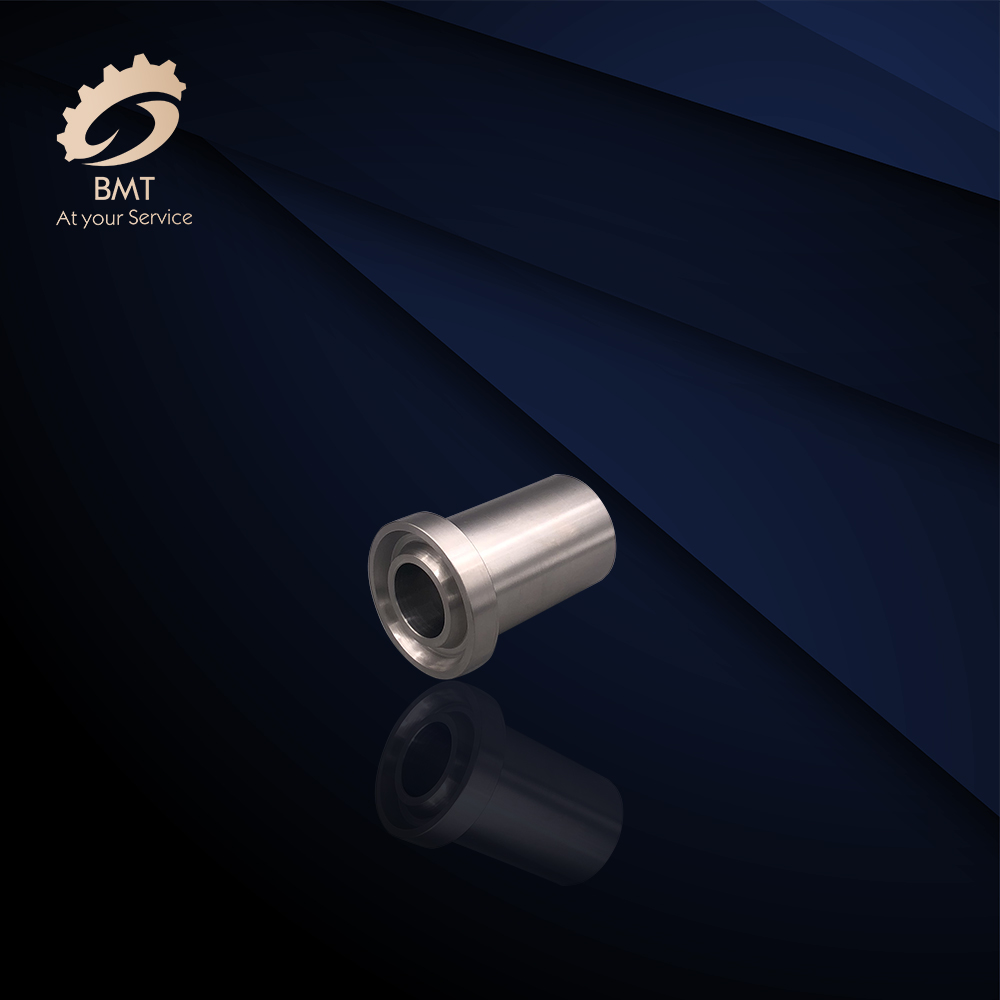

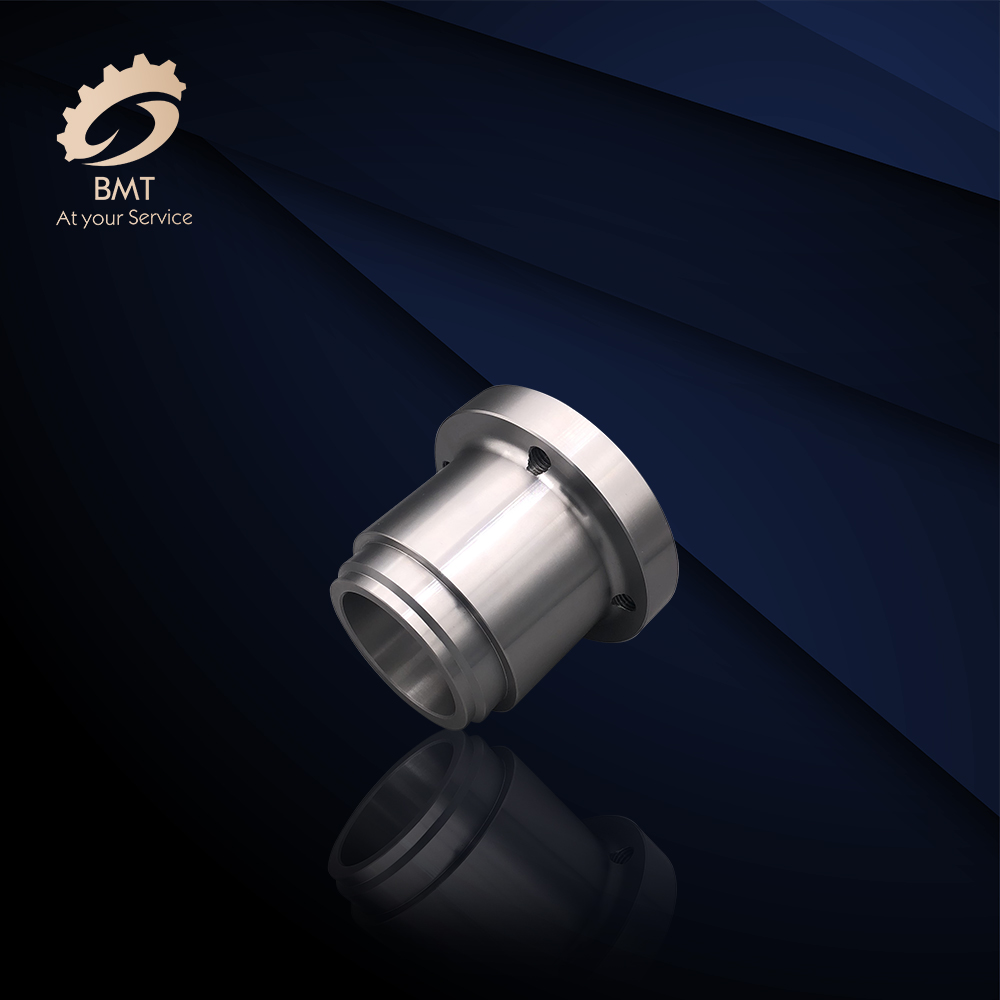

BMT yana alfaharin yin aiki tare da zaɓi na amintattun abokan ciniki, zaɓaɓɓu masu tsauri.Kowane abokin ciniki yana buƙatar bayar da mafi kyawun sassan CNC Machined.Ta hanyar kiyaye kusanci da abokan cinikinmu, BMT yana iya ba da matakan inganci na musamman.

BMT ya yi niyyar bayarwaIngantattun Abubuwan Injin CNCakan lokaci.Yana daya daga cikin dalilai masu yawa da yasa abokan cinikinmu suka amince mana da bukatun masana'anta.

Amince da mu don isar da aikin injin ɗin ku na CNC akan lokaci, zuwa ƙayyadaddun bayanai kuma a farashin gasa.