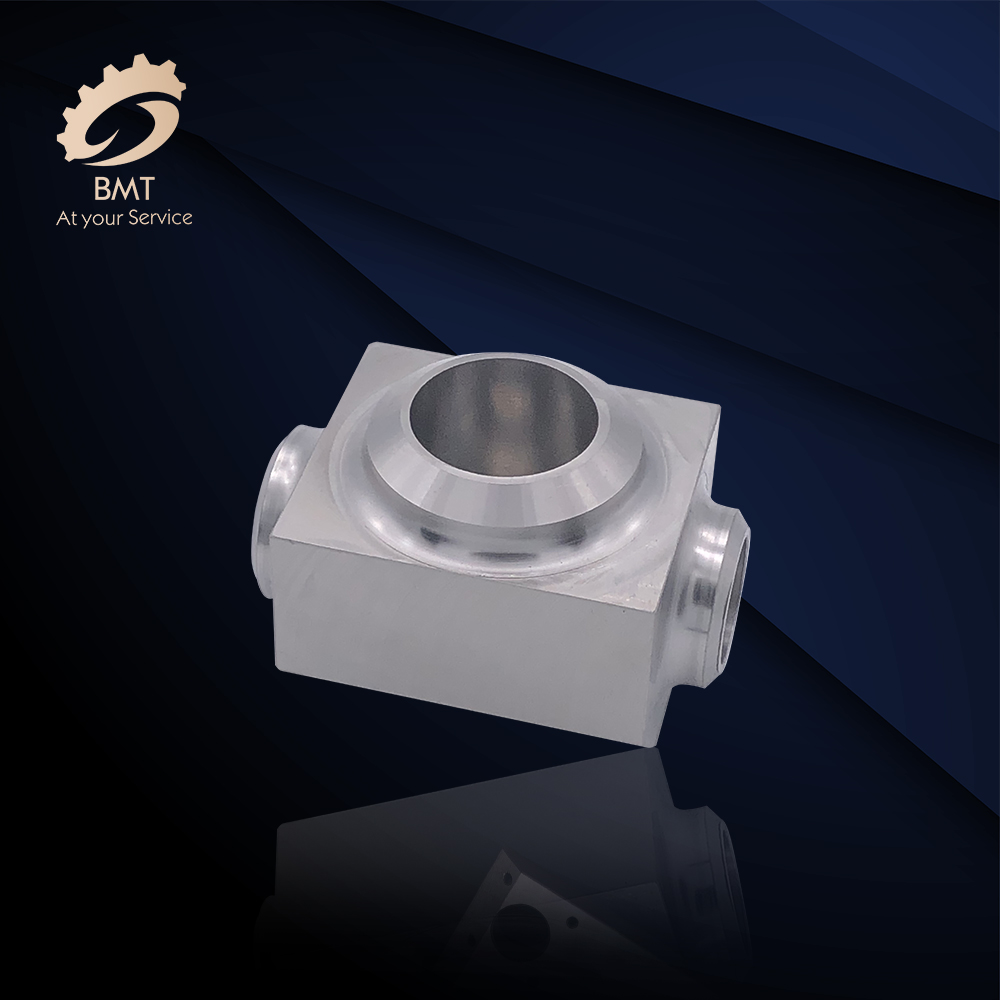

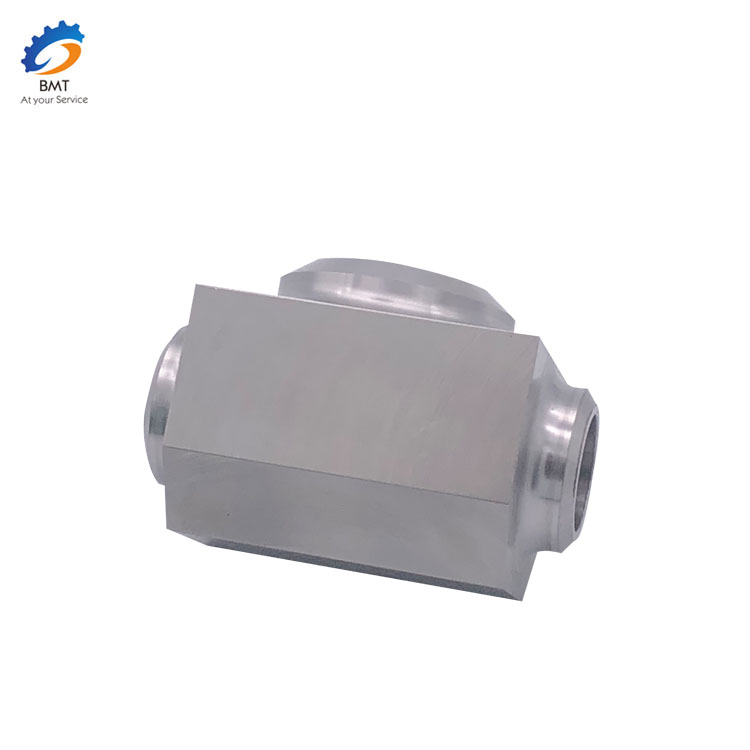

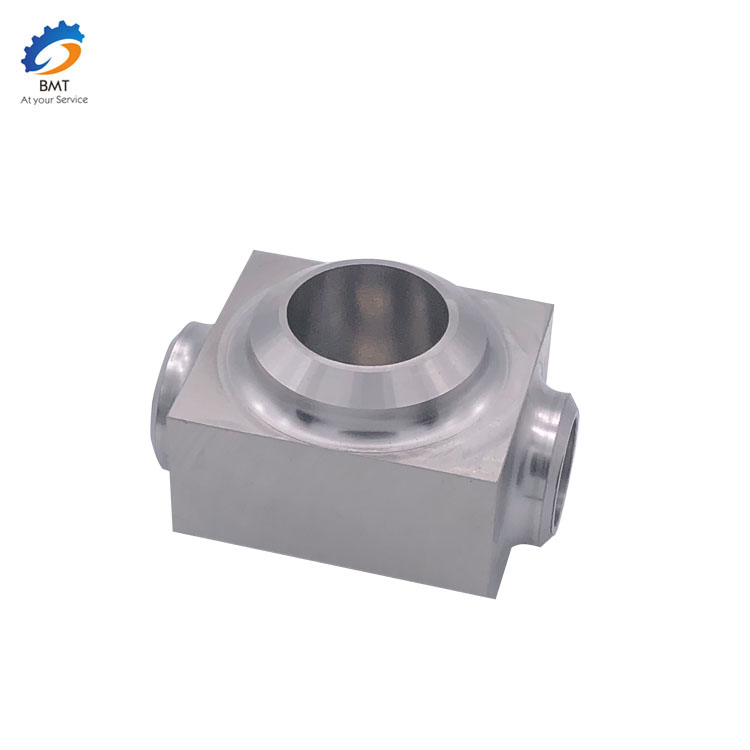

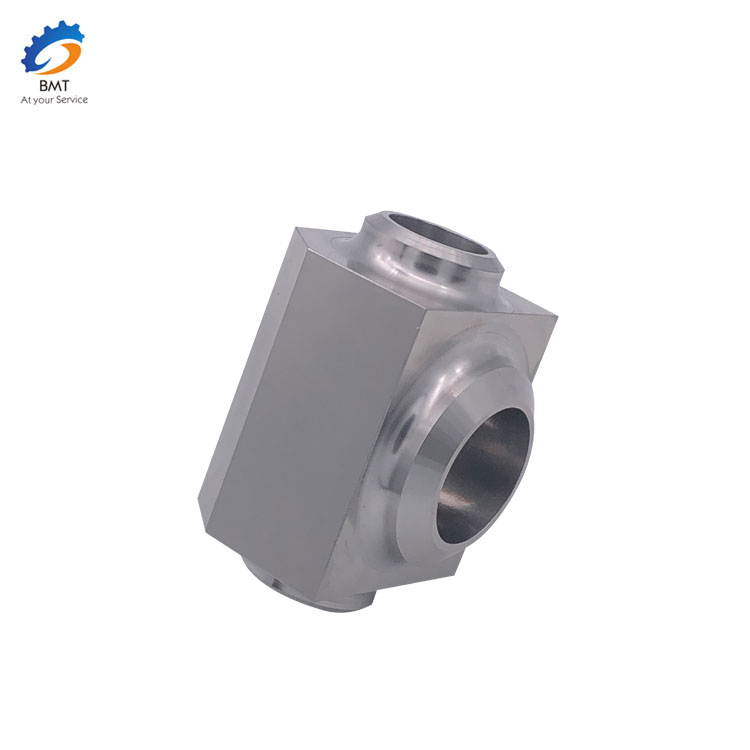

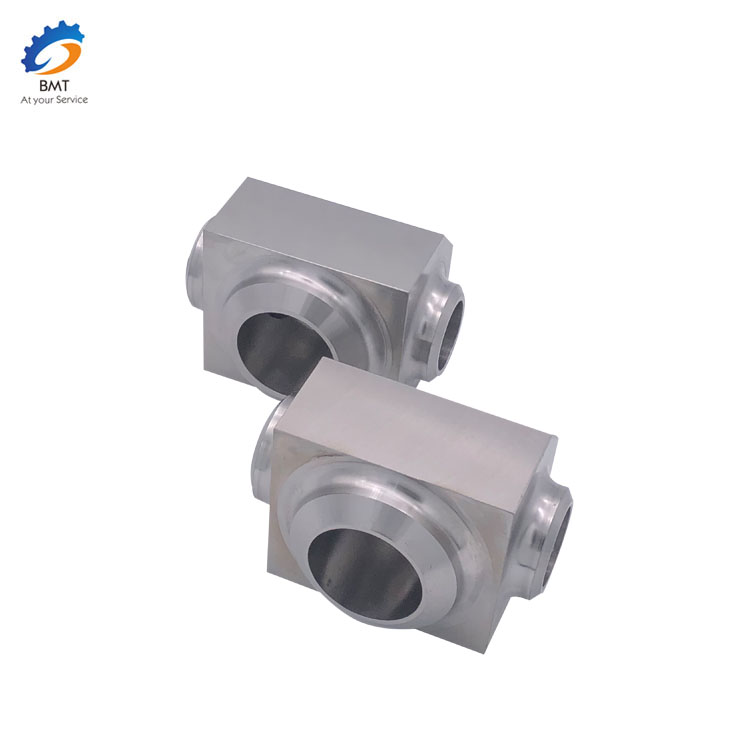

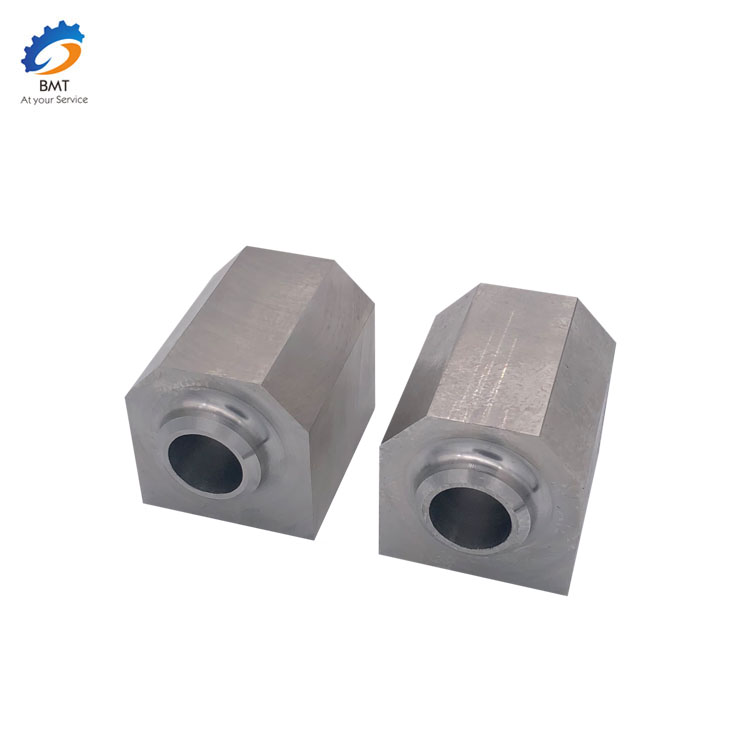

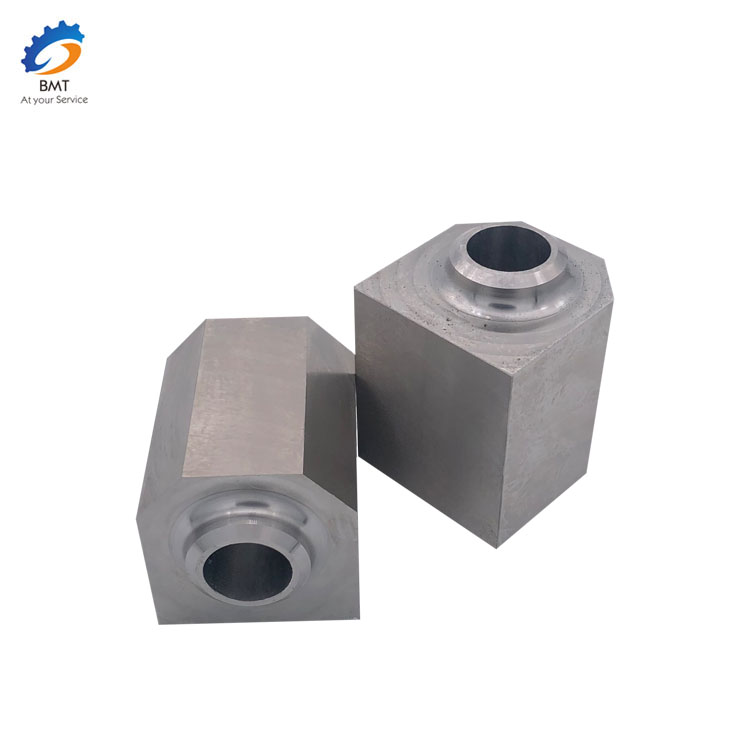

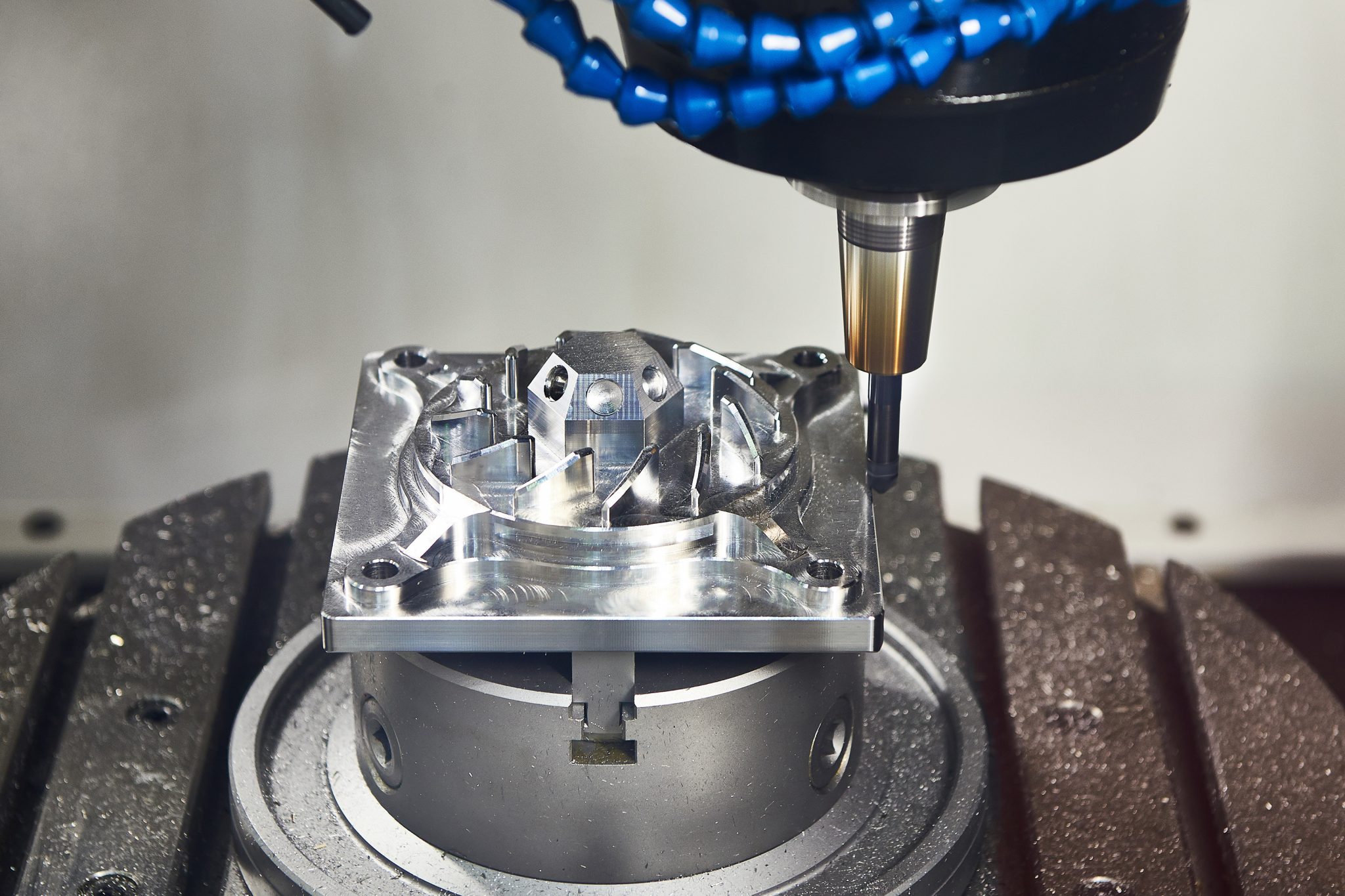

CNC Auto Parts Professional Manufacturer

BMT ƙware ne a cikin mashin ɗin daidaitaccen mashin ɗin, sarrafa kayan aikin da ba daidai ba, sarrafa manyan sassa na CNC, sarrafa sassan mota na lamba, ƙirar titanium gami a cikin manyan sassan sarrafa madaidaicin sassa, sarrafa sassan sassa, sarrafa kayan aikin semiconductor, da dai sauransu, yana da ƙwarewar ƙwarewa, sanye take tare da CNC machining cibiyar, CNC lathes, waya yankan, milling inji, nika inji, sassaka, uku daidaitawa ma'auni kayan aiki, tsawo ma'auni kayan aiki da sauran high madaidaici samar da gano kayan aiki.

1. Yi nazarin zane-zanen sarrafawa kuma ƙayyade tsarin sarrafawa

Dangane da zane-zanen da abokin ciniki ya bayar, ma'aikatan aikin na iya yin nazarin siffar, daidaiton girman girman, roughness surface, workpiece material, blank type da zafi magani yanayin sassa, sa'an nan zaɓi inji kayan aiki, kayan aiki, ƙayyade sakawa clamping. na'urar, hanyar sarrafawa, tsarin sarrafawa da girman adadin yankan.A cikin aiwatar da ƙayyadaddun tsarin mashin ɗin, aikin umarni na kayan aikin injin CNC ya kamata a yi la'akari da shi sosai, ba da cikakken wasa ga ingantaccen kayan aikin injin, ta yadda hanyar sarrafawa ta dace, ƙarancin lokutan wuka da ɗan gajeren lokacin sarrafawa.

2. Yi ƙididdige ƙimar haɗin gwiwar hanyar kayan aiki da kyau

Dangane da girman geometric na ɓangaren mashin ɗin da tsarin daidaita tsarin shirye-shiryen saiti, ana ƙididdige hanyar motsi na tsakiyar hanyar yanke, kuma ana samun duk bayanan matsayin mai yanke.Tsarin CNC na gabaɗaya yana da aikin tsaka-tsakin tsaka-tsaki da tsaka-tsakin madauwari, don sassauƙan sassa na tsari mai sauƙi, kamar sassan layi da injin kwane-kwane, kawai buƙatar ƙididdige abubuwan geometric na wurin farawa da ƙarshen ƙarshen, madauwari baka na da'irar ( ko radius madauwari), madaidaicin mahaɗar sinadari biyu na geometrical ko madaidaitan ma'ana mai daidaitawa.Idan tsarin nc ba shi da aikin ramuwa na kayan aiki, ya kamata a ƙididdige ƙimar daidaitawa na cibiyar kayan aiki.Ga sassan da ke da siffa mai rikitarwa (kamar sassan da ke tattare da lankwasa maras madauwari da saman), wajibi ne a yi amfani da sashin layi madaidaiciya (ko sashin baka) don kimanta ainihin lanƙwasa ko saman, da ƙididdige ƙimar daidaitawar sa. nodes bisa ga daidaiton injin da ake buƙata.

3. Rubuta CNC machining shirin don sassa

Dangane da sassan hanyar wuka don ƙididdige bayanan hanyar kayan aiki kuma an ƙayyade sigogin tsari da aikin taimako, ma'aikatan shirye-shirye na iya zama daidai da yin amfani da tsarin kula da NUMERICAL da aka tsara a cikin umarnin aiki da tsarin shirin, sashe ta hanyar. sashe don rubuta sassan shirin sarrafawa.Ya kamata a ba da hankali ga: na farko, daidaitattun rubutun shirye-shiryen ya kamata ya kasance mai sauƙin bayyanawa da sadarwa;Na biyu, a cikin yin amfani da kayan aikin injin CNC da umarni bisa cikakkiyar masaniya, umarnin yin amfani da ƙwarewa, ƙwarewar shirye-shirye.