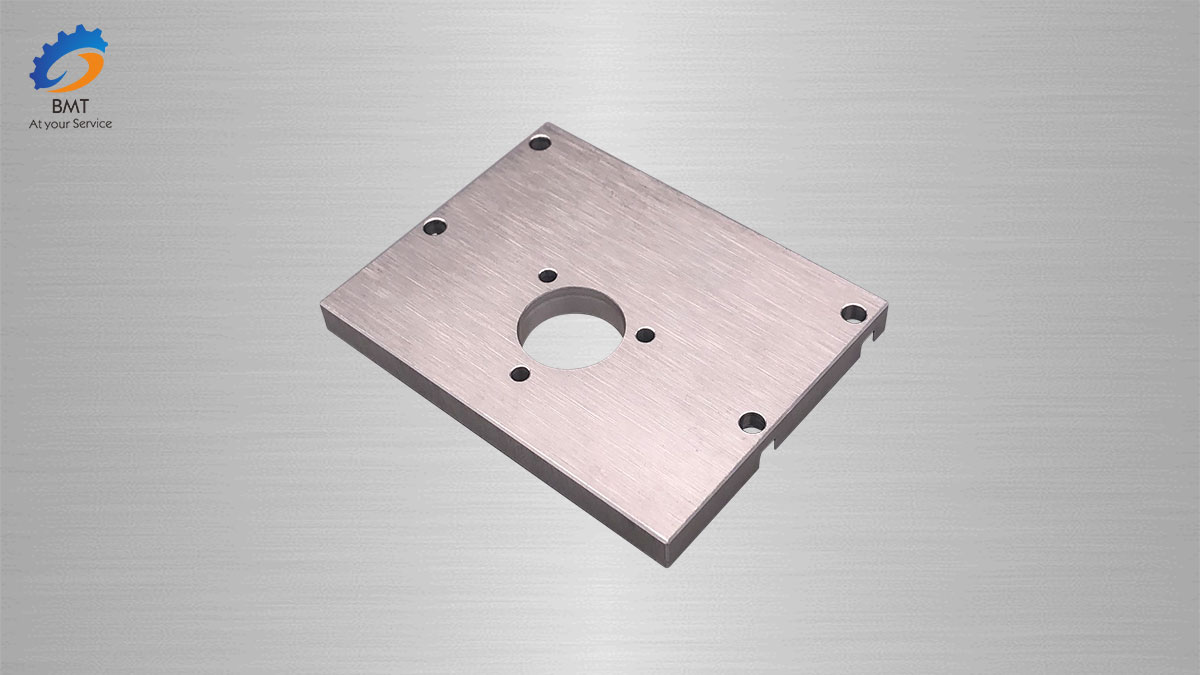

CNC Machining Processing Analysis

Binciken tsari

Abubuwan fasaha na injin CNC na sassan da aka sarrafa sun ƙunshi nau'i-nau'i masu yawa.Abubuwan da ke biyowa sun haɗu da yuwuwar da sauƙi na shirye-shirye don gabatar da wasu mahimman abubuwan da dole ne a yi nazari da sake dubawa.

Girman nadawa yakamata ya dace da halayen injinan CNC

A cikin shirye-shiryen CNC, girman da matsayi na duk maki, layi, da saman sun dogara ne akan asalin shirye-shiryen.Don haka, yana da kyau a ba da girman haɗin kai kai tsaye akan zanen ɓangaren, ko ƙoƙarin faɗi girman tare da datum iri ɗaya.

Sharuɗɗan nada abubuwa na geometric yakamata su zama cikakke kuma daidai

A cikin shirye-shiryen, dole ne mai tsara shirye-shiryen ya fahimci ma'auni na nau'in geometric wanda ya zama kwatankwacin sashin da alakar da ke tsakanin abubuwan geometric.Domin duk abubuwan geometric na kwandon sashin dole ne a bayyana su yayin shirye-shirye ta atomatik, dole ne a ƙididdige madaidaicin kowane kumburi yayin shirye-shiryen hannu.Ko da wane batu ne ba a sani ba ko rashin tabbas, ba za a iya aiwatar da shirye-shirye ba.Duk da haka, saboda rashin isassun la'akari ko rashin kulawa daga masu zanen yanki a cikin tsarin ƙira, galibi ana samun sigogi marasa cikawa ko rashin tabbas, kamar baka da madaidaiciyar layi, baka da baka ko suna tangent ko tsaka-tsaki ko rabuwa.Sabili da haka, lokacin dubawa da nazarin zane-zane, dole ne ku yi hankali kuma ku tuntuɓi mai zane a cikin lokaci idan kun sami matsala.

Dogara mai nadawa datum

A cikin mashin ɗin CNC, hanyoyin sarrafa mashin ɗin galibi suna maida hankali ne, kuma yana da matukar mahimmanci a gano su akan tushe guda.Sabili da haka, sau da yawa ya zama dole don saita wasu datums na taimako, ko ƙara wasu shuwagabannin tsari akan komai.

Ninka iri ko girman nau'in geometry iri ɗaya

Zai fi kyau a ɗauki nau'in nau'i na nau'i na geometric ko girman don siffar da rami na ciki na ɓangaren, don haka za'a iya rage yawan canjin kayan aiki, kuma yana yiwuwa a yi amfani da shirin sarrafawa ko shirin na musamman don rage tsawon tsayi. na shirin.Siffar sassan yana da mahimmanci kamar yadda zai yiwu, wanda ya dace da shirye-shirye tare da aikin injin madubi na kayan aikin CNC don adana lokacin shirye-shirye.